Product Description

Company Profile

ZheJiang Bolaige New Material Technology Co., Limited

Bolaige Fasteners was founded in 2017, is located in China ‘s largest fastener producing base -yongnian fasteners center,HangZhou ,ZheJiang province .we have 2 branch factories for manufacturing.

We main produce: Wedge anchors, Hex bolt, 8.8 High strength bolt. Hot-dip gaivanized bolt. Nut. Drop in Anchor. Self-Drilling Screw. Self Tapping Screw. Drywall Screws. Chipboard Screws. Foundation bolt, Thread bolt, sleeve anchors and electric power fitting other customize fasteners and so on .

We can produce the various standard such as : DIN, ASTM, ASME /ANSI, BS and other standards. Our products are widely used in machinery, petrochemical and other fields. We have high quality, good production capacity, punctual delivery and better after-sales evaluation. Over the past few years, we provide good service to customers from Aisa,South America ,Russia ,Middle east and so on .

We will continue to implement the “quality first, customer first” principle, to provide customers

Product Description

Product Parameters

| Item | Drywall screw |

| Material | C1571A |

| Finish | Black/Gray/zinc |

| Color | Black |

| Thread | Coarse thread |

| Length | 13-76mm |

| Size | 3.5-4.2mm |

| Application | Building,Machine parts,Furniture,Electric power fittings etc. |

Screw head type

Exhibition

Certifications

ZheJiang BOLAIGE NEW MATERIAL TECHNOLOGY CO.,LTD

Our company covers an area of 1,200 square meters, has 30 machines, nearly 100 workers, and 30 salesmen.Our main products are:

Hex bolt, Flange bolt, Allen bolt, hex socket head bolt, Hexagon socket head cap bolt, Stud bolt, U bolt, Carriage bolt, T bolt, Anchor bolt, Wedge anchor, Fix bolt, Threaded rod, Hex nut, Flange nut, Nylon nut, Weld nut, T nut, Drywall screw, Chipboard screw, Hex self drilling screw…

Packaging & Shipping

FAQ

1. When can I get my quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2. How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you need the samples, the sample is free, but you need to pay the express fee. But the express cost can be refundable after order confirmation when your quantity of the order is more about the MOQ.

3. What is your terms of payment ?

30% T/T in advance , the balance to be paid against BL copy.

4. How to order?

Step1: Just tell us the size/model and the quantity, so that we quote you first

Step2: Confirm price and order details

Step3: We will arrange production for you after receiving your deposit

5. Why choose us?

(1)Stable and traceable raw material suppling lines

(2)10 years manufacturing and exporting experience

(3)Controllable delivery time

(4)Flexible payment term

(5)Multilingual service: English/Russian/Spanish and so on.

6. How about the after service of your product?

We usually feedback within 24 hours after we get your complaint. And we can guarantee a satisfied solution to every customer.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | ANSI, DIN, GB, ISO, JIS |

|---|---|

| Type: | Common Nail |

| Material: | Steel |

| MOQ: | 1 Ton |

| Delivery: | Within 25days After Receiving Advanced Payment |

| Size: | 3.5-4.2mm |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

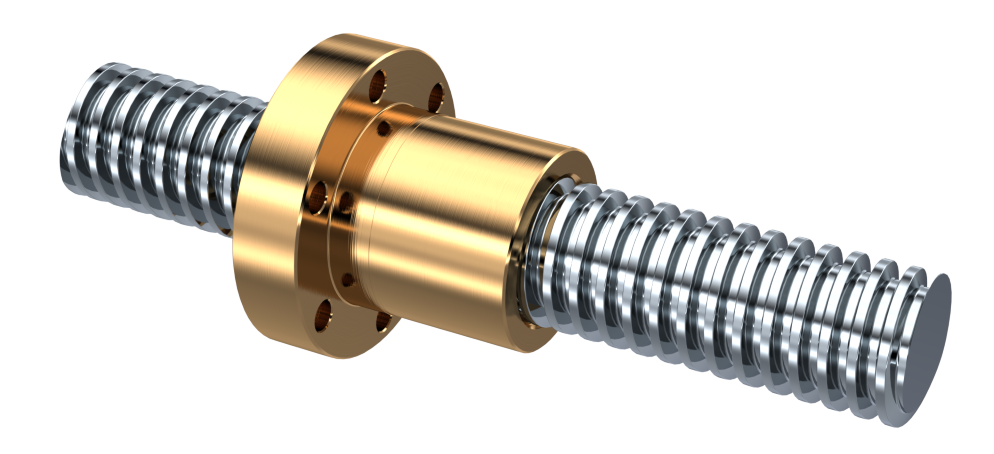

What maintenance practices are recommended for lead screws to ensure optimal functionality?

Maintaining lead screws is crucial for ensuring their optimal functionality and longevity. Regular maintenance practices can help prevent issues such as wear, backlash, and premature failure. Here are some recommended maintenance practices for lead screws:

- Cleaning: Regularly clean the lead screw and nut to remove dirt, debris, and contaminants that can cause friction and wear. Use a soft brush or cloth to gently wipe away any buildup. Avoid using abrasive materials or harsh chemicals that can damage the surfaces.

- Lubrication: Proper lubrication is essential for reducing friction and ensuring smooth operation of the lead screw. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant for the specific application. Apply the lubricant evenly along the entire length of the screw, ensuring that it reaches the threads and engages with the nut. Be careful not to over-lubricate, as excess lubricant can attract more dirt and debris.

- Inspection: Regularly inspect the lead screw for any signs of wear, damage, or misalignment. Look for excessive backlash, unusual noise during operation, or visible signs of wear on the threads. Check the nut for any signs of wear, such as uneven or flattened threads. If any issues are detected, take appropriate measures to address them, such as replacing worn components or realigning the system.

- Tension Adjustment: If the lead screw system utilizes tensioning mechanisms, such as adjustable tension nuts or spring-loaded devices, periodically check and adjust the tension as needed. Proper tension ensures proper engagement between the screw and nut, minimizing backlash and maintaining accurate positioning.

- Protection: Protect the lead screw from environmental factors that can contribute to corrosion or damage. If the lead screw is exposed to moisture, chemicals, or extreme temperatures, consider implementing protective measures such as using covers, seals, or coatings to shield the screw and nut. This is particularly important for lead screws operating in outdoor or harsh industrial environments.

- Training and Operator Practices: Provide proper training to operators who work with lead screw systems. Ensure they understand the correct operating procedures, including any specific maintenance requirements. Encourage operators to report any abnormalities or issues promptly to prevent further damage or downtime.

By following these maintenance practices, lead screw systems can operate optimally and have a longer service life. Regular cleaning, appropriate lubrication, thorough inspection, tension adjustment, protection from external factors, and proper operator practices are all essential for ensuring the optimal functionality and reliability of lead screws.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

Are there specific advantages to using lead screws over other linear motion systems?

Yes, there are specific advantages to using lead screws over other linear motion systems. Here are some of the advantages associated with lead screws:

- Precision and Accuracy: Lead screws offer precise and accurate linear motion control. The thread design and pitch allow for precise positioning and movement of components, making them suitable for applications that require high levels of accuracy and repeatability.

- Cost-Effectiveness: Lead screws are often more cost-effective compared to other linear motion systems, such as ball screws or linear actuators. They provide a reliable and efficient solution for converting rotary motion into linear motion at a relatively lower cost, making them a popular choice for many applications.

- High Load Capacity: Lead screws are capable of handling significant axial loads and torque. The thread engagement between the screw and nut distributes the load over a larger surface area, allowing lead screws to support and transfer substantial loads. This makes them suitable for applications that require heavy-duty performance and load-carrying capabilities.

- Self-Locking: Lead screws have a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads helps prevent back-driving and maintains the position of the load, providing stability and safety in applications where holding the position is critical.

- Simple Design and Installation: Lead screws have a relatively simple design, consisting of a screw and a nut. This simplicity makes them easier to install and maintain compared to more complex linear motion systems. Additionally, the straightforward design allows for customization and modification to meet specific application requirements.

- Efficiency: Lead screws can achieve high mechanical efficiency in converting rotary motion to linear motion. The efficiency depends on factors such as the thread design, lubrication, and preload. With proper design and lubrication, lead screws can operate with minimal friction and energy loss, ensuring efficient power transmission.

- Versatility: Lead screws can be used in a wide range of applications across various industries. They are suitable for applications that require linear motion, precise positioning, or adjustment of components. Lead screws find applications in industries such as manufacturing, automation, robotics, aerospace, medical, and more.

These advantages make lead screws a popular choice in many applications where precise linear motion control, cost-effectiveness, high load capacity, and simplicity are essential. However, it’s important to consider specific application requirements and factors such as speed, accuracy, duty cycle, and environmental conditions when selecting the appropriate linear motion system.

editor by CX 2024-01-17