Product Description

Introduction

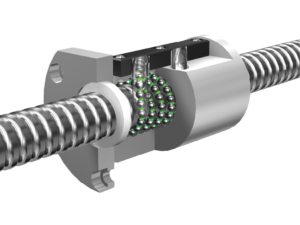

- Diameter from 4mm to 60mm for your different application, and also differenty type of nuts.

- 8mm lead screws offer an excellent way to turn rotational motion into linear motion.

-

Tr8*8-2p (4 starts),Lead Screw Diameter ∅ 8 (mm),Pitch: 2mm, Lead: 8mm

-

These Lead Screws are equipped with a large diameter that helps eliminate whipping and a high pitch which provides a quick 8mm translation for every single revolution on the screw

- The 2mm pitch offers a good trade-off between torque required to drive the screw and linear speed created. Each rotation of the lead screw will drive the mating nut precisely 8mm.

- The OD of lead-screws is just under 8mm to ensure proper fitment in an 8mm ID bearing or clamp.

-

ZS CHINAMFG screw systems feature centralizing thread forms for smooth, no-wedging performance.

-

ZS offers the largest selection of rolled CHINAMFG screw sizes in the industry. Rolled thread screws are cost effective and are stocked for quick delivery.

-

Serving a variety of functions, including fine positioning, focus adjustment, and part transport, lead screws are found in a broad spectrum of products and industries.

-

From the medical and research industries to manufacturing and packaging, lead screws are found in many applications. In addition to our basic lead screws, our design features value-added services to suit customer requirements.

-

Materials Available:Stainless Steel;Aluminum, Steel;Brass:;Bronze; Plastic;etc/as per you required

-

Processing:CNC Machining, CNC milling and turning,, grinding, bending, sheet metal fabrication,etc.

-

Surface Treatment:sand blasting, anodizing, painting,tumbling,grinding and assembling,Zinc-plated, nicke plated, chrome-plated, silver-plated, gold-plated,Passivation etc.

-

Equipments:3/4/5-axis CNC milling, CNC turning, milling machines,Grinding Machines,wire cut Machines etc;

-

Capacity:20,000 pieces per month

-

Measuring equipment:Three coordinates measuring instrument,micrometer,height gauge,hardness tester,roughness measuring instrument,caliper and various PIN gauge.

Application

- Microscopes

- Electronic Instrumentation

- Visual Inspection Equipment

- Printing, Folding, and Cutting Machines

- Blood Analyzers and ScHangZhou Machines

- 3D printers, CNC routers, lift mechanisms and automation projects.

- Precise medical devices,Industry automation,mechanical manufacturing

Feature

- High efficiency of transferring

- Good price with precision quality

- Smooth movement

- High precision, duration, and reliability

- No gap and preloading

- Produced using auto turning CNC machines

- other transmission system

- Precision ball screws

- Low friction

- Durable design

- High-speed operation* Dimension of Linear guideway

1. We have first-class testing equipment to detect linear guide various data parameters and control the quality of the linear guide.Whenever linear guides must first detected whether the quality is qualified and the unqualified linear guide will be eliminated directly.So we can get the trust of a large customer, and supply them for several years.

2. We have our own R & D capabilities, to help customers solve the problem of non-standard linear guides.We can also according to customer requirements change their own mark.

3. Price, our manufacture ensure that our prices across China are quite competitive.It is better for you to compare prices and quality among suppliers.But everyone knows you can not buy the highest quality products with the lowest price,but our product is the best quailty if you use equal price.

FAQ:

1. When can I get the quotation ?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

2. How can I get a sample to check your quality ?

After price confirmed,sample order is available to check our quality.

3. What is your main products ?

Linear motion systems,like lead screws, flexible coupling,Miniature linear guide rails,ball screws,linear rod shaft,ceramic bearings …etc. But also CNC machining centers and CNC machinable tooling boards.

4. Could you get a better price on your products ?

Yes,you can.We will give the best price on all of the products you need,which can help you to compete other companies in your markets.

5. What is the strength of your company ?

We have a engineer team,who have well experienced on product’s and machine designs.We can help you to solve the problems you meet.

Welcome to inquiry US!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Flange: | with Flange,Without Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Type: | Linear Guide Trh, Thv, Micro Type |

| Material: | Linear Guide Hgw |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What role do lead screws play in ensuring proper alignment and tightness in mechanical assemblies?

Lead screws play a crucial role in ensuring proper alignment and tightness in mechanical assemblies. They provide a reliable means of applying axial force to securely fasten components together. Here’s how lead screws contribute to alignment and tightness:

Alignment:

Lead screws aid in achieving proper alignment in mechanical assemblies through the following mechanisms:

- Linear Motion: Lead screws convert rotary motion into linear motion, allowing for controlled movement and alignment of components. By rotating the lead screw, the connected nut or threaded component moves along the screw’s axis, enabling precise positioning and alignment of the assembly.

- Thread Engagement: The mating threads of the lead screw and nut provide a positive mechanical connection. As the nut moves along the screw, the threads engage tightly, ensuring accurate alignment between the screw and the nut. This thread engagement helps maintain the desired position and alignment of components within the assembly.

- Guidance and Support: Lead screws often incorporate guidance mechanisms, such as linear bearings or sliding surfaces, to ensure smooth and accurate linear motion. These guidance systems help prevent lateral movement, minimize misalignment, and maintain the intended trajectory of the assembly, improving overall alignment.

- Positioning Accuracy: Lead screws offer precise positioning capabilities, allowing for the accurate alignment of components. The thread pitch and design, combined with the rotational input, enable controlled linear movement and positioning. This precision is critical in applications where proper alignment is essential for optimal performance and functionality.

Tightness:

Lead screws contribute to achieving tightness and secure fastening in mechanical assemblies through the following means:

- Axial Force Application: Lead screws transmit axial force to clamp or tighten components together. By rotating the lead screw, the axial force is applied through the nut or threaded component, generating a clamping action that holds the assembly tightly. This axial force helps prevent loosening, vibration, or unintended movement of the connected components.

- Self-Locking Capability: Lead screws possess a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads provides resistance to back-driving and helps maintain the tightness of the assembly. This self-locking property ensures that the assembly remains securely fastened, even in the absence of continuous power input.

- Thread Friction: The friction between the mating threads of the lead screw and nut contributes to the tightness of the assembly. When properly lubricated, the thread friction helps increase the resistance to loosening or undesired movement. By controlling the thread friction, the tightness of the assembly can be optimized to meet the specific requirements of the application.

- Preload Adjustment: Lead screws allow for preload adjustment, which is the intentional application of axial force to achieve a desired level of tightness. Preload can be applied by adjusting the initial position of the nut along the lead screw or by incorporating preload mechanisms, such as spring washers or Belleville washers. Preload optimization ensures that the assembly remains tight and secure, even under varying loads or external disturbances.

Overall, lead screws provide a reliable means of achieving proper alignment and tightness in mechanical assemblies. Their linear motion capabilities, thread engagement, guidance mechanisms, positioning accuracy, axial force application, self-locking capability, and preload adjustability all contribute to ensuring the stability, alignment, and tightness of the assembled components.

What are the signs that indicate a need for lead screw replacement or maintenance, and how can they be diagnosed?

Lead screws, like any mechanical component, may require replacement or maintenance over time due to wear, damage, or performance degradation. Recognizing the signs of potential issues and diagnosing them accurately is essential for timely intervention. Here are some common signs that indicate a need for lead screw replacement or maintenance, along with diagnostic methods:

- Increased Backlash: An increase in backlash, which is the clearance or play between the lead screw and nut, can signify wear or mechanical issues. Excessive backlash can result in decreased accuracy and precision. Diagnosis: Backlash can be measured using specialized tools, such as dial indicators or laser displacement sensors. Comparing the current backlash with the manufacturer’s specifications can help determine if maintenance or replacement is necessary.

- Unusual Noise or Vibration: Unusual noises, vibrations, or excessive mechanical resonance during operation can indicate misalignment, worn components, or inadequate lubrication. Diagnosis: Careful observation and listening during operation can help identify abnormal noise or vibration. Inspecting the lead screw for signs of wear, checking alignment, and ensuring proper lubrication can help diagnose the underlying issue.

- Reduced Accuracy or Repeatability: If a lead screw system starts exhibiting decreased accuracy or repeatability in positioning, it may indicate wear, misalignment, or damaged components. Diagnosis: Conducting precision tests or comparing the system’s actual position with the desired position can help identify any inconsistencies. Inspecting the lead screw, nut, or associated components for signs of wear or damage can provide further insights.

- Increased Friction or Sticking: If the lead screw system experiences increased friction or sticking during operation, it may indicate inadequate lubrication, contamination, or worn components. Diagnosis: Observing the smoothness of the lead screw’s movement and checking for signs of lubrication deficiency or contamination can help diagnose the issue. Cleaning the lead screw and applying appropriate lubrication may resolve minor friction-related problems.

- Visible Wear or Damage: Visual inspection of the lead screw and nut may reveal signs of wear, corrosion, or physical damage. This can include worn threads, scoring, pitting, or deformation. Diagnosis: Regular visual inspection of the lead screw system is important to identify visible signs of wear or damage. If significant wear or damage is observed, replacement or repair may be necessary.

- Inconsistent or Jerky Movement: If the lead screw system exhibits inconsistent or jerky movement instead of smooth and controlled motion, it may indicate misalignment, binding, or damaged components. Diagnosis: Careful observation of the system’s movement, checking for misalignment, and inspecting the lead screw, nut, or associated bearings for signs of binding or damage can help diagnose the issue.

It’s important to note that proper diagnosis and decision-making regarding lead screw replacement or maintenance may require the expertise of qualified technicians or engineers familiar with the specific application and system requirements. Following manufacturer guidelines, maintenance schedules, and seeking professional assistance can help ensure accurate diagnosis and appropriate actions to maintain or replace the lead screw when necessary.

In what industries or applications are lead screws commonly utilized?

Lead screws are commonly utilized in various industries and applications that require precise linear motion, positioning, or adjustment of components. Here are some of the industries and applications where lead screws are frequently used:

- CNC Machining: Lead screws play a vital role in computer numerical control (CNC) machines. They are used in the linear motion systems of CNC mills, lathes, and routers to position and move the cutting tools or workpieces with high accuracy and repeatability.

- 3D Printing: Lead screws are widely employed in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material.

- Robotics: Lead screws find extensive use in robotic systems for various applications. They are utilized in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws also enable precise linear motion in robot joints, allowing for accurate and controlled robotic movements.

- Medical Equipment: Lead screws are employed in medical equipment and devices that require precise linear motion control. They can be found in medical imaging systems, laboratory automation equipment, surgical robots, patient positioning systems, and other medical devices.

- Industrial Automation: Lead screws are utilized in industrial automation applications for precise positioning and linear motion control. They are commonly found in assembly lines, packaging machines, material handling systems, and automated testing equipment.

- Aerospace and Aviation: Lead screws find use in aerospace and aviation applications that require accurate control of movable components. They can be found in aircraft controls, navigation systems, satellite positioning mechanisms, and aerospace testing equipment.

- Optics and Photonics: Lead screws are utilized in optics and photonics applications that require precise positioning or adjustment of optical components. They can be found in telescopes, microscopes, laser systems, and optical testing equipment.

- Industrial Machinery: Lead screws are commonly used in various types of industrial machinery. They can be found in equipment such as milling machines, drilling machines, grinding machines, textile machinery, printing presses, and many other types of machinery that require controlled linear motion.

- Automation in Home and Office: Lead screws are also utilized in automation systems for home and office applications. They can be found in motorized adjustable desks, automated window blinds, camera sliders, home theater systems, and other automated systems that require precise linear motion control.

These are just a few examples of the industries and applications where lead screws are commonly utilized. The versatility, precision, and reliability of lead screws make them a valuable component in numerous mechanical systems that require controlled linear motion or positioning of components.

editor by CX 2024-01-19