Product Description

Introduction

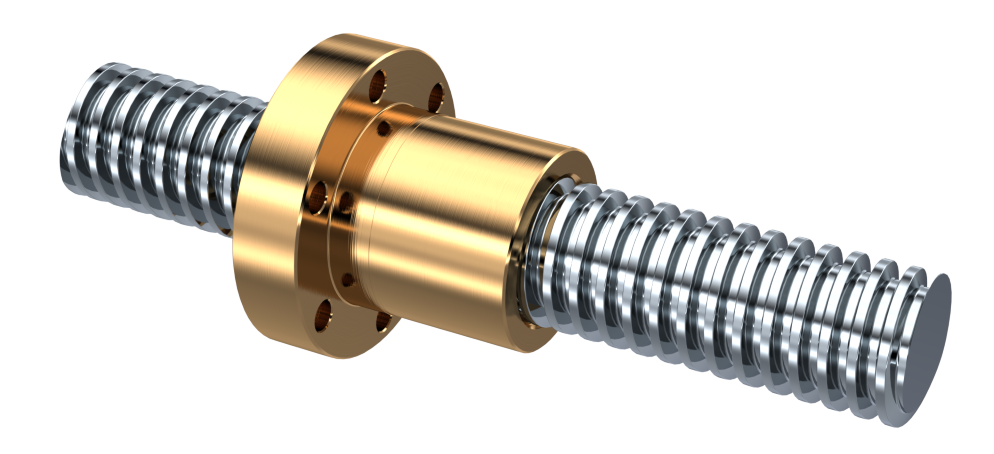

- Diameter from 4mm to 60mm for your different application, and also differenty type of nuts.

- 8mm lead screws offer an excellent way to turn rotational motion into linear motion.

-

Tr8*8-2p (4 starts),Lead Screw Diameter ∅ 8 (mm),Pitch: 2mm, Lead: 8mm

-

These Lead Screws are equipped with a large diameter that helps eliminate whipping and a high pitch which provides a quick 8mm translation for every single revolution on the screw

- The 2mm pitch offers a good trade-off between torque required to drive the screw and linear speed created. Each rotation of the lead screw will drive the mating nut precisely 8mm.

- The OD of lead-screws is just under 8mm to ensure proper fitment in an 8mm ID bearing or clamp.

-

ZS CHINAMFG screw systems feature centralizing thread forms for smooth, no-wedging performance.

-

ZS offers the largest selection of rolled CHINAMFG screw sizes in the industry. Rolled thread screws are cost effective and are stocked for quick delivery.

-

Serving a variety of functions, including fine positioning, focus adjustment, and part transport, lead screws are found in a broad spectrum of products and industries.

-

From the medical and research industries to manufacturing and packaging, lead screws are found in many applications. In addition to our basic lead screws, our design features value-added services to suit customer requirements.

-

Materials Available:Stainless Steel;Aluminum, Steel;Brass:;Bronze; Plastic;etc/as per you required

-

Processing:CNC Machining, CNC milling and turning,, grinding, bending, sheet metal fabrication,etc.

-

Surface Treatment:sand blasting, anodizing, painting,tumbling,grinding and assembling,Zinc-plated, nicke plated, chrome-plated, silver-plated, gold-plated,Passivation etc.

-

Equipments:3/4/5-axis CNC milling, CNC turning, milling machines,Grinding Machines,wire cut Machines etc;

-

Capacity:20,000 pieces per month

-

Measuring equipment:Three coordinates measuring instrument,micrometer,height gauge,hardness tester,roughness measuring instrument,caliper and various PIN gauge.

Application

- Microscopes

- Electronic Instrumentation

- Visual Inspection Equipment

- Printing, Folding, and Cutting Machines

- Blood Analyzers and ScHangZhou Machines

- 3D printers, CNC routers, lift mechanisms and automation projects.

- Precise medical devices,Industry automation,mechanical manufacturing

Feature

- High efficiency of transferring

- Good price with precision quality

- Smooth movement

- High precision, duration, and reliability

- No gap and preloading

- Produced using auto turning CNC machines

- other transmission system

- Precision ball screws

- Low friction

- Durable design

- High-speed operation* Dimension of Linear guideway

1. We have first-class testing equipment to detect linear guide various data parameters and control the quality of the linear guide.Whenever linear guides must first detected whether the quality is qualified and the unqualified linear guide will be eliminated directly.So we can get the trust of a large customer, and supply them for several years.

2. We have our own R & D capabilities, to help customers solve the problem of non-standard linear guides.We can also according to customer requirements change their own mark.

3. Price, our manufacture ensure that our prices across China are quite competitive.It is better for you to compare prices and quality among suppliers.But everyone knows you can not buy the highest quality products with the lowest price,but our product is the best quailty if you use equal price.

FAQ:

1. When can I get the quotation ?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

2. How can I get a sample to check your quality ?

After price confirmed,sample order is available to check our quality.

3. What is your main products ?

Linear motion systems,like lead screws, flexible coupling,Miniature linear guide rails,ball screws,linear rod shaft,ceramic bearings …etc. But also CNC machining centers and CNC machinable tooling boards.

4. Could you get a better price on your products ?

Yes,you can.We will give the best price on all of the products you need,which can help you to compete other companies in your markets.

5. What is the strength of your company ?

We have a engineer team,who have well experienced on product’s and machine designs.We can help you to solve the problems you meet.

Welcome to inquiry US!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Flange: | with Flange,Without Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Type: | Linear Guide Trh, Thv, Micro Type |

| Material: | Linear Guide Hgw |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that use lead screws for precise positioning?

Lead screws are widely utilized in various products and machinery that require precise positioning. Here are some examples of products and machinery that commonly use lead screws for precise positioning:

- CNC Machines: Computer numerical control (CNC) machines, including CNC mills, lathes, and routers, use lead screws to precisely position the cutting tools or workpieces. Lead screws enable accurate and repeatable movement in the linear motion systems of these machines, allowing for precise machining operations.

- 3D Printers: Lead screws are extensively used in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material, resulting in high-quality 3D prints.

- Robotics: Lead screws are integral to robotic systems that require precise positioning. They are used in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws provide accurate and controlled linear motion in robot joints, allowing for precise and coordinated movements in industrial, medical, and research robotics.

- Medical Imaging Systems: Lead screws are employed in medical imaging systems, such as computed tomography (CT) scanners and magnetic resonance imaging (MRI) machines, to precisely position the patient bed or gantry. This precise positioning is crucial for accurate imaging and diagnosis.

- Laboratory Automation Equipment: Lead screws are used in laboratory automation equipment, such as liquid handling robots and sample handling systems, for precise positioning and movement of samples, reagents, and labware. They ensure accurate and repeatable positioning required for various laboratory processes.

- Semiconductor Manufacturing Equipment: Lead screws are utilized in semiconductor manufacturing equipment, including wafer handling systems and lithography machines. They provide precise positioning and movement of wafers, masks, and other components critical for semiconductor fabrication processes.

- Camera Sliders: Lead screws are employed in camera sliders used in photography and videography applications. They enable smooth and precise linear motion of the camera along the slider, allowing for controlled tracking shots and precise camera positioning.

- Telescopes and Astronomy Equipment: Lead screws are utilized in telescopes and other astronomy equipment to precisely position optical components and achieve accurate tracking of celestial objects. They enable fine adjustments and precise pointing of telescopes for astronomical observations.

- Industrial Inspection Systems: Lead screws are used in industrial inspection systems, such as coordinate measuring machines (CMMs) and optical inspection systems, for precise movement and positioning of the inspection probes or cameras. This ensures accurate measurement and inspection of manufactured components.

These are just a few examples of the products and machinery that utilize lead screws for precise positioning. The versatility, accuracy, and reliability of lead screws make them a preferred choice in applications that require controlled linear motion and precise positioning of components.

Can you explain the impact of lead screws on the overall durability of mechanical systems?

Lead screws have a significant impact on the overall durability of mechanical systems. As essential components in many machines and mechanisms, lead screws play a crucial role in providing precise linear motion and transferring loads. Their design, quality, and maintenance directly influence the durability and reliability of the systems they are incorporated into. Here are some key factors highlighting the impact of lead screws on overall durability:

- Load-Carrying Capacity: Lead screws are responsible for transmitting axial loads between the rotating screw and the nut. The design and material selection of the lead screw determine its load-carrying capacity. Inadequate design or material choice can lead to premature wear, deformation, or failure under heavy loads, compromising the overall durability of the mechanical system.

- Backlash and Precision: Backlash refers to the play or clearance between the screw and nut in a lead screw system. Excessive backlash can result in reduced precision, inaccuracies in positioning, and decreased overall performance. Lead screws with low backlash, such as ball screws, are often preferred in applications that require high precision and repeatability. Minimizing backlash through proper design and maintenance enhances the durability and performance of the system.

- Wear and Friction: Lead screws are subject to wear and friction during operation. Continuous contact between the screw and nut can result in surface damage and increased friction, leading to accelerated wear. Adequate lubrication, regular maintenance, and proper material selection can help minimize wear and friction, extending the lifespan of the lead screw and improving the durability of the mechanical system.

- Mechanical Efficiency: The efficiency of a lead screw system influences its durability. Inefficient systems generate more heat due to friction, which can cause thermal expansion, accelerated wear, and reduced lifespan. By selecting lead screw designs with high mechanical efficiency, such as ball screws or optimized thread profiles, the overall durability of the mechanical system can be improved.

- Environmental Considerations: Lead screws operating in different environments face varying challenges that can impact their durability. Factors such as temperature extremes, exposure to moisture, chemicals, or abrasive contaminants can accelerate wear, corrosion, or degradation of the lead screw. Proper material selection, protective coatings, sealing, and regular maintenance practices can mitigate the environmental impact and enhance the overall durability of the mechanical system.

- Maintenance and Service Life: Adequate maintenance practices, including cleaning, lubrication, inspection, and adjustment, are essential for preserving the durability of lead screws and the mechanical systems they are part of. Regular maintenance helps identify and address issues early, preventing further damage and extending the service life of the system.

In conclusion, lead screws have a significant impact on the overall durability of mechanical systems. Their load-carrying capacity, precision, wear characteristics, mechanical efficiency, environmental resistance, and proper maintenance practices all contribute to the durability, reliability, and performance of the system. By considering these factors and selecting suitable lead screw designs, materials, and maintenance strategies, the overall durability of mechanical systems can be significantly improved.

Can you explain the role of a lead screw in converting rotary motion to linear motion?

A lead screw plays a crucial role in converting rotary motion into linear motion in mechanical systems. It achieves this by utilizing the helical threads on the screw and the corresponding threads on the nut. Here’s a detailed explanation of how a lead screw accomplishes the conversion:

- Helical Thread Design: A lead screw is designed with a helical thread that wraps around its cylindrical shaft. The thread is typically a continuous spiral groove with a specific pitch, which is the distance between adjacent threads. The pitch determines the linear distance the nut will travel when the lead screw makes one complete revolution.

- Matching Threaded Nut: The lead screw is paired with a nut that has threads matching those on the screw. The nut is typically fixed in place while the lead screw rotates. The nut contains internal threads that engage with the external threads of the lead screw.

- Rotary Motion: When the lead screw is rotated, either manually or by a motor-driven mechanism, the helical threads on the screw cause the nut to move linearly along the length of the screw. The direction and magnitude of the linear motion depend on the direction and speed of the screw’s rotation.

- Linear Motion: As the lead screw rotates, the engaged threads between the screw and the nut create a force that translates the rotational motion into linear motion. The helical threads on the screw push against the matching threads in the nut, causing the nut to move along the length of the screw. This results in linear displacement of the nut and any attached components.

- Precision and Control: The pitch of the lead screw determines the linear distance traveled by the nut for each revolution of the screw. By controlling the rotational motion of the lead screw, precise and controlled linear movement can be achieved. This makes lead screws suitable for applications that require accurate positioning or adjustment of components.

- Load Capacity: Lead screws can handle both axial loads (tension or compression forces) and torque. The helical threads distribute the load over a larger surface area, allowing the lead screw to support and transfer significant loads. By incorporating thrust bearings or other supporting elements, the lead screw can handle high loads while maintaining smooth and controlled linear motion.

Overall, the lead screw’s role in converting rotary motion to linear motion relies on the interaction between the helical threads of the lead screw and the matching threads of the nut. This mechanism provides a reliable and precise means to translate rotational motion into linear displacement, making lead screws a valuable component in various mechanical systems and applications.

editor by CX 2024-02-24