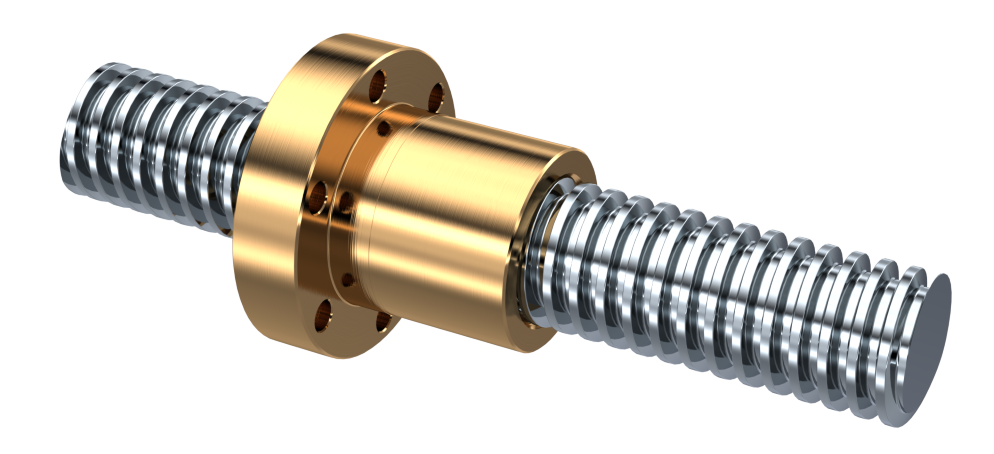

Product Description

The ball screw is a crucial component in automation equipment, designed to provide smooth and precise linear motion. It consists of a screw shaft and a nut assembly, with ball bearings circulating between them. This mechanism enables efficient transfer of rotational motion into linear motion, resulting in high accuracy and repeatability.

The ball screw is widely used in various industries, including manufacturing, automotive, aerospace, and robotics. Its exceptional performance makes it an essential element in automation systems, where precision and reliability are paramount.

Detailed Photos

Product Parameters

Cold rolled ball screw application:

1. Engraving machine; 2. High speed CNC machinery;

4. Automated machinery. 3. Semiconductor equipment;

5. Machine tool; 6. Industrial machinery;

7. Printing machine; 8. Paper machine;

9. Textile machinery; 10. Electronic machinery;

11. Transportation machinery; 12. Robots, etc

Rolling ball screws can not only be used in the above-mentioned general machinery, but also in many advanced industries. Ball screw assembly with electric motor for electromechanical actuators is more environmentally friendly than hydraulic pump systems. Now it has been applied to electric vehicles, Solar power station, railway equipment and many medical and leisure equipment.

Basic information

| Model | SSR2510 | Types | Outer Loop |

| ODM | Yes | OEM | Yes |

| Number of scrolling columns | 3-Row | Number of nuts | Single |

| With or without flanges | With flange | Accuracy | C5 |

| Outer diameter of screw rod | 31-40mm | Screw shaft length | customizable |

| Thread direction | Left/Right | Hardness | 58-62HRC |

| Nut raw materials | 20crmo | Raw materials of screw rod | S55C |

| Country of origin | ZHangZhoug China | Transport packaging | Wooden box/export standard packaging |

| HS CODE | 848390009 | certificate | ISO9001:2000 |

Company Profile

ZHangZhoug Weimute Technology Co., Ltd. was founded in 2016 and located in HangZhou, ZHangZhoug Province. Superior location and convenient transportation. We have extensive industry experience and are a trustworthy supplier. The company has advanced production equipment and skilled frontline employees. Our company mainly engages in the production and sales of linear motion bearing series, slider series, ball screw series, linear guide rail series, flange linear bearing series, cylinder linear guide rail series, joint bearing series, rod end bearing series, radial spherical bearing sliding bearing series, and wheel pin bearing series.Our company knows that its development depends on product innovation and quality. Therefore, our products have strict quality control from raw material procurement to finished product sales. The company has established a quality management system that meets the requirements of the international quality management system. The company continuously innovates according to market and customer needs, always maintaining the novelty and innovation of its products. Our company’s products are sold worldwide. The company has won unanimous recognition from consumers with satisfactory product quality and comprehensive after-sales service. We have a professional research and development team. We can accept OE M and ODM. We sincerely welcome friends from all over the world to visit our company and cooperate with us on the basis of long-term mutual benefit. We look CHINAMFG to receiving your inquiry soon.

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a factory.

Q2: How long does your delivery time and shipping time take?

1. Sample delivery time: Generally 7 working days.

2. Production delivery time: 15-20 working days after receiving the deposit.

Q3: Can we provide free samples?

A: Yes, we provide the samples for free, but you will need to bear the shipping cost.

Q4: What payment methods are accepted?

A: We accept payment through TT (bank transfer), L/C, Western Union.

Q5: What are your strengths?

1. Manufacturers with the most competitive prices and good quality.

2. Perfect technical engineers provide you with the best support.

3. OEM available.

4. Rich inventory and fast delivery.

Q6. If you cannot find the product on our website, what should you do next?

A: Please send us an inquiry with product images and drawings via email or other means, and we will check.

Q7: When can I receive the quotation?

We usually provide a quotation within 24 hours after receiving your inquiry. If you are very eager to obtain a price, please call us or let us know in your email so that we can prioritize your inquiry.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5 |

|---|---|

| Screw Diameter: | 31-40mm |

| Flange: | With Flange |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can lead screws be customized for specific industries or machinery configurations?

Yes, lead screws can be customized to meet the specific requirements of different industries or machinery configurations. Customization allows for the adaptation of lead screws to unique applications, ensuring optimal performance and compatibility. Here’s how lead screws can be customized:

Thread Design:

The thread design of lead screws can be customized to suit specific applications. The thread profile, such as Acme, square, or buttress, can be selected based on factors such as load capacity, efficiency, backlash, and self-locking characteristics. The thread pitch can be adjusted to achieve the desired linear travel per revolution, allowing for different positioning resolutions. Custom thread designs can also be implemented to address specific requirements or constraints of the machinery configuration.

Materials and Coatings:

The choice of materials for lead screws can be customized based on the application’s environmental conditions and performance requirements. Different materials, such as stainless steel, carbon steel, or alloys, can be selected for their mechanical properties, corrosion resistance, or temperature resistance. Additionally, lead screws can be coated or treated with specialized coatings, such as Teflon or ceramic coatings, to reduce friction, improve wear resistance, or enhance lubrication properties.

Size and Dimensions:

The size and dimensions of lead screws can be customized to fit specific machinery configurations or space constraints. This includes variations in length, diameter, and thread length to ensure proper fit and integration within the machinery or system. Customization of lead screw dimensions allows for efficient utilization of available space and compatibility with existing components or mounting mechanisms.

End Machining:

Lead screws can be customized with different types of end machining to facilitate their connection to other components or power sources. This may involve the addition of keyways, flats, or other features to enable coupling with drive mechanisms, such as motors or handwheels. Customized end machining ensures proper alignment, torque transmission, and ease of installation within the specific machinery configuration.

Accessories and Attachments:

Customization of lead screws can also involve the addition of accessories or attachments to enhance their functionality or compatibility with specific industries or machinery configurations. This may include the inclusion of anti-backlash nuts, thrust bearings, lubrication systems, or wipers. These accessories and attachments can improve precision, reduce wear, increase load capacity, or address specific application requirements.

By offering customization options, lead screw manufacturers can cater to the diverse needs of different industries and machinery configurations. Customized lead screws ensure that the linear motion system is optimized for performance, efficiency, and compatibility, resulting in improved overall functionality and reliability.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

Can you describe the various types and configurations of lead screws available in the market?

Lead screws are available in various types and configurations to suit different applications and requirements. Here’s an overview of the common types and configurations of lead screws found in the market:

- Acme Lead Screws: Acme lead screws are one of the most widely used types. They have a trapezoidal thread profile with a 29-degree thread angle. Acme screws are known for their strength, durability, and high load-carrying capacity. They offer efficient linear motion conversion and are commonly used in applications that require heavy-duty and high-load capabilities.

- Ball Screws: Ball screws are precision lead screws that incorporate ball bearings between the screw and nut. The ball bearings reduce friction, allowing for smoother and more efficient linear motion. Ball screws offer high accuracy, low backlash, and excellent repeatability. They are commonly used in applications that require high precision, such as CNC machines, robotics, and semiconductor manufacturing equipment.

- Stub Acme Screws: Stub Acme screws are similar to Acme screws but have a shallower thread depth. They offer higher efficiency and smoother operation compared to Acme screws. Stub Acme screws are commonly used in applications where space is limited or when a lighter load capacity is required.

- Buttress Screws: Buttress screws have a thread profile with one flank at a 45-degree angle and the other flank perpendicular to the screw axis. This design provides high load-carrying capacity in one direction while allowing for easy movement in the opposite direction. Buttress screws are commonly used in applications that require the transmission of heavy axial loads in a single direction, such as presses or jacks.

- Multiple-Start Screws: Multiple-start screws have two or more threads wrapped around the screw shaft. This design allows for faster linear travel per revolution compared to single-start screws. Multiple-start screws are used in applications where higher linear speeds or quick linear positioning is required.

- Thread Forms: Apart from the specific types mentioned above, lead screws can also come in different thread forms to suit specific applications. Some common thread forms include square threads, triangular threads, and rounded threads. These thread forms offer variations in load-carrying capacity, efficiency, backlash, and cost, providing options to meet specific application requirements.

- Lead Screw Configurations: Lead screws can be found in various configurations depending on the specific application. Some configurations include:

- – Standard Lead Screws: These are the most common configurations with a cylindrical shaft and threads along its length.

- – Flanged Lead Screws: These lead screws have a flange at one or both ends, providing support and alignment in certain applications.

- – Anti-Backlash Lead Screws: These lead screws incorporate mechanisms to minimize or eliminate backlash, providing more precise linear motion control.

- – Customized Lead Screws: Lead screws can be customized to meet specific application requirements, such as specific dimensions, thread pitch, end machining, or material selection.

These are some of the common types and configurations of lead screws available in the market. The selection of the appropriate lead screw type depends on factors such as load requirements, precision needs, speed, backlash tolerance, and specific application constraints.

editor by Dream 2024-04-23