Product Description

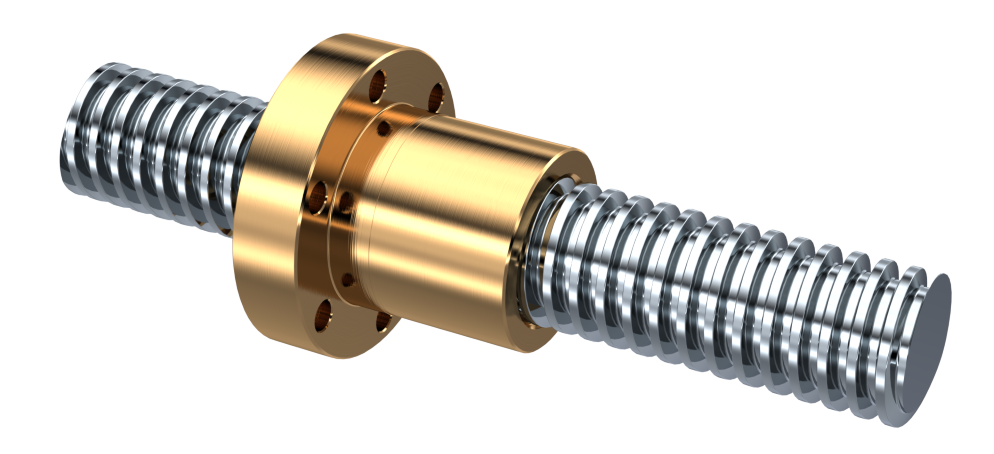

GSR Series of Cold Rolled Ball Screw (C5 / Ct7 / Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

GSR series (cold rolled ball screw and precision ball screw) and BBS series (stainless steel cold rolled ball screw) have 3 precision grades jisC5/ Ct7 /Ct10.

The axial clearance is provided according to the accuracy level 0.005mm / 0.02mm/ 0.05mm .

Material & Surface Hardness

GSR series (cold rolling ball screw and precision ball ) screw shaft screw material S55C (high frequency quenching), nut material scm415h (carburizing quenching), surface hardness of ball screw part is above hrc58.

The screw shaft screw material SUS440C (high frequency quenching) and nut material sus440 (vacuum quenching) of BBS series(stainless steel cold rolling ball screw). The surface hardness of the ball screw part is above HRC55.

Lubrication

In order to prevent rusting,GSR series (cold rolled ball screw and precision ball screw) and BBS series stainless steel cold rolled ball screw products that are not processed on the shaft end are coated with anti-rust oil. Since anti show oil does not have lubricity, please apply lubricant separately before use.

Shaft End Shape

The shaft end shape of GSR series (cold rolled ball screw,precision ball screw) is standardized.

Fast Delivery Time

The GSR series which has not been processed at the shaft end has been standardized, and has been kept delivered in time all the year round. Screw rod and nut can be ordered separately.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5 |

|---|---|

| Screw Diameter: | 5mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 3-Row |

| Nut Type: | Circulator |

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that use lead screws for precise positioning?

Lead screws are widely utilized in various products and machinery that require precise positioning. Here are some examples of products and machinery that commonly use lead screws for precise positioning:

- CNC Machines: Computer numerical control (CNC) machines, including CNC mills, lathes, and routers, use lead screws to precisely position the cutting tools or workpieces. Lead screws enable accurate and repeatable movement in the linear motion systems of these machines, allowing for precise machining operations.

- 3D Printers: Lead screws are extensively used in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material, resulting in high-quality 3D prints.

- Robotics: Lead screws are integral to robotic systems that require precise positioning. They are used in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws provide accurate and controlled linear motion in robot joints, allowing for precise and coordinated movements in industrial, medical, and research robotics.

- Medical Imaging Systems: Lead screws are employed in medical imaging systems, such as computed tomography (CT) scanners and magnetic resonance imaging (MRI) machines, to precisely position the patient bed or gantry. This precise positioning is crucial for accurate imaging and diagnosis.

- Laboratory Automation Equipment: Lead screws are used in laboratory automation equipment, such as liquid handling robots and sample handling systems, for precise positioning and movement of samples, reagents, and labware. They ensure accurate and repeatable positioning required for various laboratory processes.

- Semiconductor Manufacturing Equipment: Lead screws are utilized in semiconductor manufacturing equipment, including wafer handling systems and lithography machines. They provide precise positioning and movement of wafers, masks, and other components critical for semiconductor fabrication processes.

- Camera Sliders: Lead screws are employed in camera sliders used in photography and videography applications. They enable smooth and precise linear motion of the camera along the slider, allowing for controlled tracking shots and precise camera positioning.

- Telescopes and Astronomy Equipment: Lead screws are utilized in telescopes and other astronomy equipment to precisely position optical components and achieve accurate tracking of celestial objects. They enable fine adjustments and precise pointing of telescopes for astronomical observations.

- Industrial Inspection Systems: Lead screws are used in industrial inspection systems, such as coordinate measuring machines (CMMs) and optical inspection systems, for precise movement and positioning of the inspection probes or cameras. This ensures accurate measurement and inspection of manufactured components.

These are just a few examples of the products and machinery that utilize lead screws for precise positioning. The versatility, accuracy, and reliability of lead screws make them a preferred choice in applications that require controlled linear motion and precise positioning of components.

Are there innovations or advancements in lead screw technology that have emerged in recent years?

In recent years, there have been notable innovations and advancements in lead screw technology aimed at improving performance, efficiency, precision, and durability. These advancements have been driven by the demand for more sophisticated machinery and automation systems. Here are some key innovations in lead screw technology that have emerged in recent years:

- Anti-Backlash Designs: Backlash, which refers to the play or clearance between the screw and nut, has been a longstanding challenge in lead screw systems. To address this issue, innovative anti-backlash designs have been developed. These designs incorporate mechanisms such as preloading systems, split nuts, or adjustable axial play to minimize or eliminate backlash, resulting in improved precision and repeatability.

- High-Efficiency Thread Profiles: Traditional lead screws often feature trapezoidal or ACME thread profiles, which can result in higher friction and lower mechanical efficiency. Recent advancements have introduced new thread profiles, such as the “triangular” or “wedge” profiles, which optimize the contact area between the screw and nut, reducing friction and improving mechanical efficiency. These high-efficiency thread profiles offer smoother operation, increased load-carrying capacity, and improved energy efficiency.

- Lead Screw Coatings and Surface Treatments: Coatings and surface treatments have been developed to enhance the durability, wear resistance, and lubrication properties of lead screws. For example, advanced coatings like Teflon, ceramic, or DLC (Diamond-Like Carbon) coatings provide low friction, reduce wear, and improve the lifespan of the lead screw. These coatings also help prevent contaminants from adhering to the surfaces, minimizing the risk of damage or performance degradation.

- Integrated Lubrication Systems: Lubrication is crucial for smooth operation and longevity of lead screws. Recent advancements have introduced integrated lubrication systems that automatically deliver a controlled amount of lubricant to the screw and nut. These systems ensure consistent and optimal lubrication, reducing friction, wear, and the need for manual lubrication maintenance. Integrated lubrication systems can be particularly beneficial in applications where access to the lead screw is limited or in environments where contamination risks are high.

- Smart and Connected Lead Screw Systems: The rise of Industry 4.0 and the Internet of Things (IoT) has led to the development of smart and connected lead screw systems. These systems feature embedded sensors, communication capabilities, and data analytics algorithms. They enable real-time monitoring of operating parameters, condition monitoring, predictive maintenance, and performance optimization. Smart lead screw systems provide valuable insights, enhance operational efficiency, and reduce downtime by enabling proactive maintenance and troubleshooting.

- Hybrid Lead Screw Technologies: Hybrid lead screw technologies combine the advantages of different types of screws, such as combining a traditional lead screw with a ball screw or roller screw elements. This fusion results in enhanced performance characteristics, such as increased load capacity, improved efficiency, reduced friction, and higher precision. Hybrid lead screws offer a cost-effective alternative to high-precision ball screws while providing superior performance compared to traditional lead screws.

These recent innovations and advancements in lead screw technology have significantly improved the performance, efficiency, precision, and durability of lead screw systems. Anti-backlash designs, high-efficiency thread profiles, advanced coatings, integrated lubrication systems, smart and connected features, and hybrid technologies have expanded the capabilities and application range of lead screws in various industries, including aerospace, automotive, robotics, and industrial automation.

What is a lead screw, and how is it used in mechanical applications?

A lead screw is a type of threaded shaft used in mechanical applications to convert rotary motion into linear motion or vice versa. It consists of a screw with a helical thread and a matching nut with corresponding threads. The lead screw and nut are designed in such a way that when the screw is rotated, it moves the nut along its length, resulting in linear motion.

The primary purpose of a lead screw is to transmit motion and force between rotating and linearly translating components in a mechanical system. It offers precise control over linear movement and is commonly used in various applications, including but not limited to:

- Precision Positioning: Lead screws are widely used in applications that require precise positioning, such as CNC machines, 3D printers, and robotic systems. By coupling the lead screw to a motor or handwheel, the rotational motion can be translated into precise linear movement, allowing for accurate positioning of components or tools.

- Actuation and Adjustment: Lead screws are often utilized for actuation and adjustment mechanisms in equipment and machinery. They can be employed to raise or lower platforms, adjust the height of work surfaces, control the position of tool heads, or move components along a linear path. Lead screws provide a straightforward and reliable means of achieving controlled linear motion in these applications.

- Load Transfer: Lead screws can also serve as load-bearing elements in mechanical systems. They can transmit axial loads and handle tension or compression forces, making them suitable for applications that require smooth and controlled lifting or lowering of heavy loads. In such cases, the lead screw is often combined with thrust bearings or other supporting elements to handle the applied loads.

- Manual and Handwheel Operations: Lead screws are commonly used in manual and handwheel-operated systems. By incorporating a handle or handwheel, the user can rotate the lead screw directly, enabling manual adjustment or movement of components. This is frequently seen in applications like manual stage positioning, height adjustment mechanisms, or manual clamping systems.

- Power Transmission: In some cases, lead screws can be employed for power transmission purposes. While they are not as efficient as other transmission methods like gears or belts, lead screws can be used to transfer torque between rotating shafts and linearly translating components. This is often seen in applications where the primary focus is on converting rotational motion into linear motion rather than optimizing power transmission efficiency.

Lead screws come in various designs, including single-start and multi-start threads, different thread pitches, and varying lead screw and nut materials. The selection of a lead screw depends on the specific requirements of the application, such as load capacity, desired speed, precision, and environmental conditions. Factors like backlash, efficiency, and maintenance requirements should also be considered when choosing a lead screw for a particular mechanical application.

editor by Dream 2024-05-06