Product Description

China Ball Screw Manufacturer/Factory/Supplier Ball Screw (6mm-80mm) with Nut (SFNU SFS SFA SFI SFY SFK BSH SCI)

Product Description

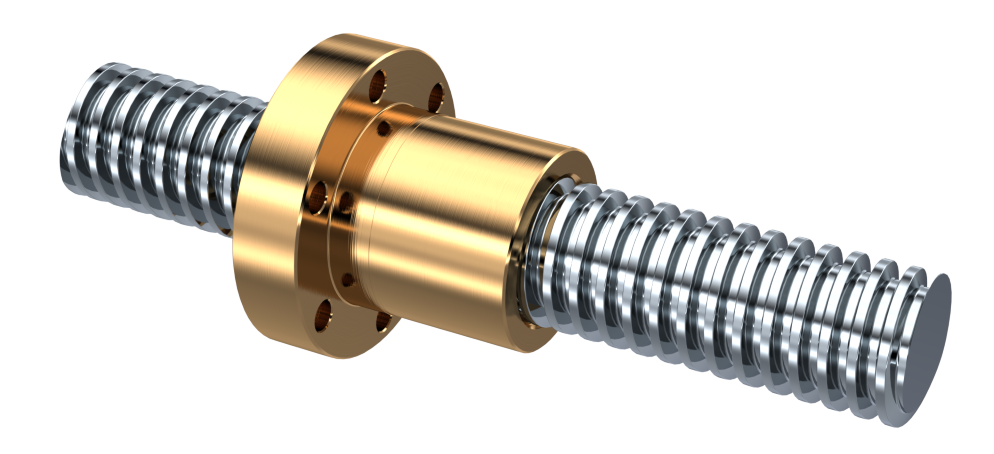

Ball Screw is made of screw and ball nut. It’s function is to turn the rotary motion into linear motion which is a future extension and development of ball screw. The significance of the development is to move into a rolling bearing from sliding action. With little frication, Ball Screw are widely used into various industrial equipment and precision instruments.

| Ball Srew Series | |

| Diameter6mm | 0601 |

| Diameter8mm | 0801 0802 |

| Diameter10mm | 1002 1004 |

| Diameter12mm | |

| Diameter16mm | |

| Diameter20mm | |

| Diameter25mm | |

| Diameter32mm | |

| Diameter40mm | |

| Diameter50mm | |

| Diameter63mm | 6310 6320 |

| Diameter80mm | 8571 |

| SFU Ball Screw Nut Model No.(plastic deflector or metal deflector ) | ||||||

| SFU1204-3;SFU1605-3;SFU1605-4; SFU1610-2; SFU2005-3;SFU2005-4;SFU2505-3; | ||||||

| SFU2505-4;SFU2510-4;SFU3205-3;SFU3205-4;SFU4005-4;SFU4571-4; SFU5571-4; | ||||||

| SFU6310-4;SFU8571-4 | ||||||

| SFK Ball Screw Model No. | ||||||

| SFK0601;SFK0801;SFK0802;SFK082.5;SFK1002;SFK1004;SFK1202;SFK1402 | ||||||

| SFS Ball Screw Model No. | ||||||

| SFS1205;SFS1210;SFS1605;SFS1610;SFS1616;SFS1620;SFS2571;SFS2510;SFS2525;SFS3210;SFS4571 | ||||||

| SFI Ball Screw Model No. | ||||||

| SFI1605;SFI1610;SFI2005;SFI2505;SFI2510;SFI3205;SFI3210;SFI4005;SFI4571 | ||||||

| SFE Ball Screw Model No. | ||||||

| SFE1616;SFE2571;SFE2525;SFE3232;SFE4040 | ||||||

| SFY Ball Screw Model No. | ||||||

| SFY1616;SFY2571;SFY2525;SFY3232;SFY4040 | ||||||

| SFA Ball Screw Model No. | ||||||

| SFA1205;SFA1210;SFA1605;SFA1610;SFA1616;SFA1620;SFA2571;SFA2510;SFA2525;SFA3210;SFA4571 | ||||||

| Ball Screw End Supports Model No. | ||||||

| BK10 BF10, BK12 BF12, BK15 BF15, BK17 BF17, BK20 BF20, BK25 BF25, | ||||||

| BK30 BF30, BK35 BF35, BK40 BF40 | ||||||

| EK06 EF06, EK08 EF08, EK10 EF10, EK12 EF12, EK15 EF15, EK20 EF20; EK25 EF25 | ||||||

| FK06 FF6, FK08 FF08,FK10 FF10, FK12 FF12, FK15 FF15, FK20 FF20, FK25 FF25, FK30 FF30 | ||||||

| Ball Screw Nut Housings Model No. (Aluminium or Iron) | ||||||

| DSG12H(1204),DSG16H(1605/1610), DSG20H(2005/2571), DSG25H(2505/2510), | ||||||

| DSG32H(3205/3210),DSG40H(4005/4571),DSG50H(5005/5571) |

Features

1.High-speed operation

2.Low friction and noise

3.High precision, duration, and reliability

4.Smooth movement

5.High efficiency of transferring

6.No gap and preloading

Applications

1.Machine tools

2.Industrial machinery

3.Printing, paper-processing, automatic machines, textiles, etc.

4.Electronic machinery

5.Robot, measuring instruments, medical equipment, X-Y table, factory automation equipment

6.Transport machinery

Detailed Photos

Product Parameters

Ball Screw Set: Ball Screw, Ball Screw Nut, Ball Screw Nut Housing,Ball Screw End Support(Fixed Side and Floated Side),Coupling; We can supply those together for you.

Ball Screw End Machining: Standard machining according to End Support Units or Customized according to drawing.

HangZhou City CHINAMFG Bearing Co., Ltd. is a professional manufacturer of linear motion products with many years’ experience. We are specialized in the producing linear shaft, linear guides, ball screws, linear bearings, linear guide blocks, ball screw end supports, linear rails, cam followers with good quality and competitive price. Our company is located in HangZhou city, ZHangZhoug province, close to HangZhou port and HangZhou city.

Our products are widely used in precise machines, fitness equipment, printing machines, packing machines, medical and food machines, textile machinery and other machines and supplementary equipment. Our products sell well in North America, West Europe, Australia, Southeast Asia, Middle East, South America and other regions.

After Sales Service

Our Quality:

Quality is the life . We use only the best quality material to ensure the standard of our product range is of the highest caliber.All products we sold out are strictly selected and tested by our QC department.

Warranty:

All products may have problem after used by a period of time. We provide 1 year warranty for all products.

Payment:

We accept payment via TT (Bank transfer), Paypal,Western Union, and Money Gram.

We accept bank transfer for large orders. For small order, you’d better pay via Paypal,Western union or Money Gram

Shipping:

We offer as many shipping options as possible, including DHL, UPS, TNT, FEDEX and EMS, Airfreight and by Sea.

FAQ

1. Are you factory or trading company?

We are professional manufacturer with most competitive price and high quality, 15 year’s experience.

2.What’s your product range?

We are specialized in producing linear shafts, linear bearings, linear guides, linear rails, ball screws,cam follower and other linear motion units.

3.Do you offer OEM&ODM services?

Yes, OEM, ODM is welcomed

4.How Can I get some samples?

We are honored to offer samples. You are requested to pay the shipping cost and some samples cost.

5.What does your factory do about quality control?

We uphold the tenet of “Quality is the future, we have passed ISO9001 certification, and we have strict procedures to control quality.

6. How can I get a quotation?

You can send quotation below or email to us. you can contact dirrectly with us through TM or WhatsApp,Skype as you like.Call any time if you are urgent.

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can you provide examples of products or machinery that use lead screws for precise positioning?

Lead screws are widely utilized in various products and machinery that require precise positioning. Here are some examples of products and machinery that commonly use lead screws for precise positioning:

- CNC Machines: Computer numerical control (CNC) machines, including CNC mills, lathes, and routers, use lead screws to precisely position the cutting tools or workpieces. Lead screws enable accurate and repeatable movement in the linear motion systems of these machines, allowing for precise machining operations.

- 3D Printers: Lead screws are extensively used in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material, resulting in high-quality 3D prints.

- Robotics: Lead screws are integral to robotic systems that require precise positioning. They are used in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws provide accurate and controlled linear motion in robot joints, allowing for precise and coordinated movements in industrial, medical, and research robotics.

- Medical Imaging Systems: Lead screws are employed in medical imaging systems, such as computed tomography (CT) scanners and magnetic resonance imaging (MRI) machines, to precisely position the patient bed or gantry. This precise positioning is crucial for accurate imaging and diagnosis.

- Laboratory Automation Equipment: Lead screws are used in laboratory automation equipment, such as liquid handling robots and sample handling systems, for precise positioning and movement of samples, reagents, and labware. They ensure accurate and repeatable positioning required for various laboratory processes.

- Semiconductor Manufacturing Equipment: Lead screws are utilized in semiconductor manufacturing equipment, including wafer handling systems and lithography machines. They provide precise positioning and movement of wafers, masks, and other components critical for semiconductor fabrication processes.

- Camera Sliders: Lead screws are employed in camera sliders used in photography and videography applications. They enable smooth and precise linear motion of the camera along the slider, allowing for controlled tracking shots and precise camera positioning.

- Telescopes and Astronomy Equipment: Lead screws are utilized in telescopes and other astronomy equipment to precisely position optical components and achieve accurate tracking of celestial objects. They enable fine adjustments and precise pointing of telescopes for astronomical observations.

- Industrial Inspection Systems: Lead screws are used in industrial inspection systems, such as coordinate measuring machines (CMMs) and optical inspection systems, for precise movement and positioning of the inspection probes or cameras. This ensures accurate measurement and inspection of manufactured components.

These are just a few examples of the products and machinery that utilize lead screws for precise positioning. The versatility, accuracy, and reliability of lead screws make them a preferred choice in applications that require controlled linear motion and precise positioning of components.

Can you explain the impact of lead screws on the overall durability of mechanical systems?

Lead screws have a significant impact on the overall durability of mechanical systems. As essential components in many machines and mechanisms, lead screws play a crucial role in providing precise linear motion and transferring loads. Their design, quality, and maintenance directly influence the durability and reliability of the systems they are incorporated into. Here are some key factors highlighting the impact of lead screws on overall durability:

- Load-Carrying Capacity: Lead screws are responsible for transmitting axial loads between the rotating screw and the nut. The design and material selection of the lead screw determine its load-carrying capacity. Inadequate design or material choice can lead to premature wear, deformation, or failure under heavy loads, compromising the overall durability of the mechanical system.

- Backlash and Precision: Backlash refers to the play or clearance between the screw and nut in a lead screw system. Excessive backlash can result in reduced precision, inaccuracies in positioning, and decreased overall performance. Lead screws with low backlash, such as ball screws, are often preferred in applications that require high precision and repeatability. Minimizing backlash through proper design and maintenance enhances the durability and performance of the system.

- Wear and Friction: Lead screws are subject to wear and friction during operation. Continuous contact between the screw and nut can result in surface damage and increased friction, leading to accelerated wear. Adequate lubrication, regular maintenance, and proper material selection can help minimize wear and friction, extending the lifespan of the lead screw and improving the durability of the mechanical system.

- Mechanical Efficiency: The efficiency of a lead screw system influences its durability. Inefficient systems generate more heat due to friction, which can cause thermal expansion, accelerated wear, and reduced lifespan. By selecting lead screw designs with high mechanical efficiency, such as ball screws or optimized thread profiles, the overall durability of the mechanical system can be improved.

- Environmental Considerations: Lead screws operating in different environments face varying challenges that can impact their durability. Factors such as temperature extremes, exposure to moisture, chemicals, or abrasive contaminants can accelerate wear, corrosion, or degradation of the lead screw. Proper material selection, protective coatings, sealing, and regular maintenance practices can mitigate the environmental impact and enhance the overall durability of the mechanical system.

- Maintenance and Service Life: Adequate maintenance practices, including cleaning, lubrication, inspection, and adjustment, are essential for preserving the durability of lead screws and the mechanical systems they are part of. Regular maintenance helps identify and address issues early, preventing further damage and extending the service life of the system.

In conclusion, lead screws have a significant impact on the overall durability of mechanical systems. Their load-carrying capacity, precision, wear characteristics, mechanical efficiency, environmental resistance, and proper maintenance practices all contribute to the durability, reliability, and performance of the system. By considering these factors and selecting suitable lead screw designs, materials, and maintenance strategies, the overall durability of mechanical systems can be significantly improved.

Can you describe the various types and configurations of lead screws available in the market?

Lead screws are available in various types and configurations to suit different applications and requirements. Here’s an overview of the common types and configurations of lead screws found in the market:

- Acme Lead Screws: Acme lead screws are one of the most widely used types. They have a trapezoidal thread profile with a 29-degree thread angle. Acme screws are known for their strength, durability, and high load-carrying capacity. They offer efficient linear motion conversion and are commonly used in applications that require heavy-duty and high-load capabilities.

- Ball Screws: Ball screws are precision lead screws that incorporate ball bearings between the screw and nut. The ball bearings reduce friction, allowing for smoother and more efficient linear motion. Ball screws offer high accuracy, low backlash, and excellent repeatability. They are commonly used in applications that require high precision, such as CNC machines, robotics, and semiconductor manufacturing equipment.

- Stub Acme Screws: Stub Acme screws are similar to Acme screws but have a shallower thread depth. They offer higher efficiency and smoother operation compared to Acme screws. Stub Acme screws are commonly used in applications where space is limited or when a lighter load capacity is required.

- Buttress Screws: Buttress screws have a thread profile with one flank at a 45-degree angle and the other flank perpendicular to the screw axis. This design provides high load-carrying capacity in one direction while allowing for easy movement in the opposite direction. Buttress screws are commonly used in applications that require the transmission of heavy axial loads in a single direction, such as presses or jacks.

- Multiple-Start Screws: Multiple-start screws have two or more threads wrapped around the screw shaft. This design allows for faster linear travel per revolution compared to single-start screws. Multiple-start screws are used in applications where higher linear speeds or quick linear positioning is required.

- Thread Forms: Apart from the specific types mentioned above, lead screws can also come in different thread forms to suit specific applications. Some common thread forms include square threads, triangular threads, and rounded threads. These thread forms offer variations in load-carrying capacity, efficiency, backlash, and cost, providing options to meet specific application requirements.

- Lead Screw Configurations: Lead screws can be found in various configurations depending on the specific application. Some configurations include:

- – Standard Lead Screws: These are the most common configurations with a cylindrical shaft and threads along its length.

- – Flanged Lead Screws: These lead screws have a flange at one or both ends, providing support and alignment in certain applications.

- – Anti-Backlash Lead Screws: These lead screws incorporate mechanisms to minimize or eliminate backlash, providing more precise linear motion control.

- – Customized Lead Screws: Lead screws can be customized to meet specific application requirements, such as specific dimensions, thread pitch, end machining, or material selection.

These are some of the common types and configurations of lead screws available in the market. The selection of the appropriate lead screw type depends on factors such as load requirements, precision needs, speed, backlash tolerance, and specific application constraints.

<img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l1.webp" alt="China Hot selling China Factory Precision Ballscrew Rolled Ground Ball Screw (6mm-80mm) with Nut (SFNU SFS SFA SFH SFI SFY SFE SFK BSH) Tbi Size Miniature/Big Lead for CNC Router “><img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l2.webp" alt="China Hot selling China Factory Precision Ballscrew Rolled Ground Ball Screw (6mm-80mm) with Nut (SFNU SFS SFA SFH SFI SFY SFE SFK BSH) Tbi Size Miniature/Big Lead for CNC Router “>

editor by Dream 2024-10-08