Product Description

C1571A single lead thread yellow zinc plated 3.0mm-6.0mm chipboard Screws

Product Parameters

| Product name: | chipboard screw |

| Material | C1571A |

| Shank diameter | 3.0mm-6.0mm |

| Length | 19mm-100mm |

| Surface treatment | Electric galvanized, white zinc plated or yellow zinc plated |

| Standard | DIN / ISO / GB |

| Logo | If you need, we provide logo customization service |

| Mark: | According to customer’s requirement |

| Delivery time: | Normally in15-40 days. |

| packing: | bulk package in woven bags or carton, small box as the customer requirement |

| Payment term | 30% TT in advance and 70% TT before shipment |

| Usage | Building construction, decoration field, wooden furniture, electrical component, household and so on |

Company Profile

ZheZheJiang nruifeng Technology Co., Ltd., was established in 2008 and its business covers fastener design, manufacturing and export. We have 3 production bases, with a total area of 16,000 square meters. Our main products include drywall screws, chipboard screws, self-drilling screws and self-tapping screws. We can also provide other fasteners, like nails, staples, blind rivets, anchors, bolts and nuts.

We have 280 sets of automatic production equipment, including wire drawing machines, cold-heading machines, thread rolling machines, tailing machines and heat-treatment lines. We are your one-stop manufacturer from raw material to final products. Our annual production capacity reaches up to 30,000 tons, 70% of which are exported to different countries and regions.

ZheZheJiang nruifeng Technology Co., Ltd. has been in the fastener industry for 1 years and we can customize all kinds of products per your requirements. We have an established management system and quality control procedure. Excellent quality, competitive price and timely delivery are the pillars of the company’s foundation. Win-win and long-term cooperation are our final goals when dealing with different clients.

Packaging & Shipping

After Sales Service

Q: You are a manufacturing company or trading company?

A: We are screws and fastener manufacturing in ZheJiang city of china.

Q: Wonder if you accept small orders?

A: Do not worry. Please feel free to contact us, in order to give our clients more convenience ,we accept small order.

Q: Can we print our the package with own logo ?

A: Yes, we can make it according to your request.

Q: Can we provide the sample ?

A: Yes, the sample will be free to the customer, but the Express fee will be paid from you.

Q: Can you customized the head mark?

A: Yes, welcome customized, all products as your demand.

Q: How long is your delivery time?

A: Generally it is 20-30 days accoding to the order quantity, we need time the prepare the raw material and dies accoding the order.

Q: What is your payment term?

A: Generally, 30% T/T in advance ,balance payment before shippment.

Others products

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can you provide examples of products or machinery that use lead screws for precise positioning?

Lead screws are widely utilized in various products and machinery that require precise positioning. Here are some examples of products and machinery that commonly use lead screws for precise positioning:

- CNC Machines: Computer numerical control (CNC) machines, including CNC mills, lathes, and routers, use lead screws to precisely position the cutting tools or workpieces. Lead screws enable accurate and repeatable movement in the linear motion systems of these machines, allowing for precise machining operations.

- 3D Printers: Lead screws are extensively used in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material, resulting in high-quality 3D prints.

- Robotics: Lead screws are integral to robotic systems that require precise positioning. They are used in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws provide accurate and controlled linear motion in robot joints, allowing for precise and coordinated movements in industrial, medical, and research robotics.

- Medical Imaging Systems: Lead screws are employed in medical imaging systems, such as computed tomography (CT) scanners and magnetic resonance imaging (MRI) machines, to precisely position the patient bed or gantry. This precise positioning is crucial for accurate imaging and diagnosis.

- Laboratory Automation Equipment: Lead screws are used in laboratory automation equipment, such as liquid handling robots and sample handling systems, for precise positioning and movement of samples, reagents, and labware. They ensure accurate and repeatable positioning required for various laboratory processes.

- Semiconductor Manufacturing Equipment: Lead screws are utilized in semiconductor manufacturing equipment, including wafer handling systems and lithography machines. They provide precise positioning and movement of wafers, masks, and other components critical for semiconductor fabrication processes.

- Camera Sliders: Lead screws are employed in camera sliders used in photography and videography applications. They enable smooth and precise linear motion of the camera along the slider, allowing for controlled tracking shots and precise camera positioning.

- Telescopes and Astronomy Equipment: Lead screws are utilized in telescopes and other astronomy equipment to precisely position optical components and achieve accurate tracking of celestial objects. They enable fine adjustments and precise pointing of telescopes for astronomical observations.

- Industrial Inspection Systems: Lead screws are used in industrial inspection systems, such as coordinate measuring machines (CMMs) and optical inspection systems, for precise movement and positioning of the inspection probes or cameras. This ensures accurate measurement and inspection of manufactured components.

These are just a few examples of the products and machinery that utilize lead screws for precise positioning. The versatility, accuracy, and reliability of lead screws make them a preferred choice in applications that require controlled linear motion and precise positioning of components.

What are the signs that indicate a need for lead screw replacement or maintenance, and how can they be diagnosed?

Lead screws, like any mechanical component, may require replacement or maintenance over time due to wear, damage, or performance degradation. Recognizing the signs of potential issues and diagnosing them accurately is essential for timely intervention. Here are some common signs that indicate a need for lead screw replacement or maintenance, along with diagnostic methods:

- Increased Backlash: An increase in backlash, which is the clearance or play between the lead screw and nut, can signify wear or mechanical issues. Excessive backlash can result in decreased accuracy and precision. Diagnosis: Backlash can be measured using specialized tools, such as dial indicators or laser displacement sensors. Comparing the current backlash with the manufacturer’s specifications can help determine if maintenance or replacement is necessary.

- Unusual Noise or Vibration: Unusual noises, vibrations, or excessive mechanical resonance during operation can indicate misalignment, worn components, or inadequate lubrication. Diagnosis: Careful observation and listening during operation can help identify abnormal noise or vibration. Inspecting the lead screw for signs of wear, checking alignment, and ensuring proper lubrication can help diagnose the underlying issue.

- Reduced Accuracy or Repeatability: If a lead screw system starts exhibiting decreased accuracy or repeatability in positioning, it may indicate wear, misalignment, or damaged components. Diagnosis: Conducting precision tests or comparing the system’s actual position with the desired position can help identify any inconsistencies. Inspecting the lead screw, nut, or associated components for signs of wear or damage can provide further insights.

- Increased Friction or Sticking: If the lead screw system experiences increased friction or sticking during operation, it may indicate inadequate lubrication, contamination, or worn components. Diagnosis: Observing the smoothness of the lead screw’s movement and checking for signs of lubrication deficiency or contamination can help diagnose the issue. Cleaning the lead screw and applying appropriate lubrication may resolve minor friction-related problems.

- Visible Wear or Damage: Visual inspection of the lead screw and nut may reveal signs of wear, corrosion, or physical damage. This can include worn threads, scoring, pitting, or deformation. Diagnosis: Regular visual inspection of the lead screw system is important to identify visible signs of wear or damage. If significant wear or damage is observed, replacement or repair may be necessary.

- Inconsistent or Jerky Movement: If the lead screw system exhibits inconsistent or jerky movement instead of smooth and controlled motion, it may indicate misalignment, binding, or damaged components. Diagnosis: Careful observation of the system’s movement, checking for misalignment, and inspecting the lead screw, nut, or associated bearings for signs of binding or damage can help diagnose the issue.

It’s important to note that proper diagnosis and decision-making regarding lead screw replacement or maintenance may require the expertise of qualified technicians or engineers familiar with the specific application and system requirements. Following manufacturer guidelines, maintenance schedules, and seeking professional assistance can help ensure accurate diagnosis and appropriate actions to maintain or replace the lead screw when necessary.

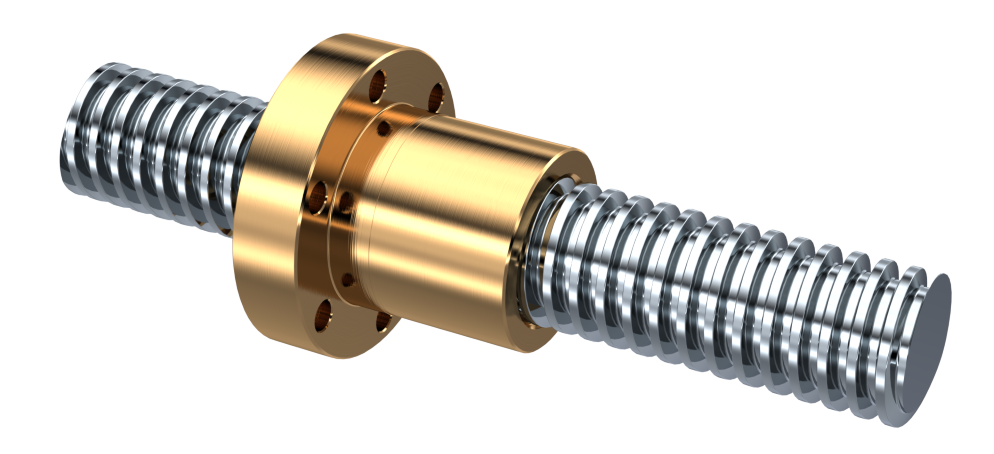

How does a lead screw differ from other types of screws in terms of design and functionality?

A lead screw differs from other types of screws in terms of its design and functionality. Here’s a detailed explanation of the distinctions between lead screws and other screw types:

- Thread Design: Lead screws have a helical thread design, meaning the threads wrap around the screw’s cylindrical shaft in a continuous spiral. This helical thread allows for the conversion of rotary motion into linear motion. In contrast, other types of screws, such as machine screws or wood screws, typically have a straight or tapered thread design suited for fastening or joining applications.

- Linear Motion Conversion: The primary function of a lead screw is to convert rotary motion into linear motion or vice versa. It achieves this by utilizing the engagement between the helical threads on the screw and the matching threads on the nut. This capability makes lead screws suitable for applications requiring precise positioning, actuation, or adjustment of components along a linear path. In contrast, other screws are primarily used for fastening, joining, or securing objects together.

- Precision and Control: Lead screws offer precise control over linear movement due to their thread pitch and the ability to rotate the screw with precision. The pitch determines the linear distance the nut will travel for each revolution of the screw. This feature makes lead screws well-suited for applications that demand accurate positioning or adjustment. In contrast, other screws are not designed with the same level of precision or control over linear motion.

- Load Handling: Lead screws are designed to handle both axial loads (tension or compression forces) and torque. The helical threads and the engagement between the screw and nut distribute the load over a larger surface area, allowing lead screws to support and transfer significant loads. Other screw types, such as machine screws or wood screws, are primarily used for fastening and may not have the same load-bearing capabilities as lead screws.

- Applications: Lead screws find applications in various mechanical systems that require precise linear motion, such as CNC machines, 3D printers, robotic systems, and adjustable mechanisms. They are commonly used for positioning, actuation, or adjustment purposes. Conversely, other types of screws serve different purposes, such as machine screws used for fastening components together, wood screws for joining wooden materials, or self-tapping screws for creating threads in materials like metal or plastic.

Overall, the key differences between lead screws and other types of screws lie in their thread design, their ability to convert rotary motion to linear motion, the precision and control they offer, their load-handling capabilities, and the specific applications they are designed for. Understanding these distinctions is essential when selecting the appropriate screw type for a particular mechanical application.

<img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l1.webp" alt="China best C1022A Single Lead Thread Yellow Zinc Plated 3.0mm-6.0mm Chipboard Screws “><img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l2.webp" alt="China best C1022A Single Lead Thread Yellow Zinc Plated 3.0mm-6.0mm Chipboard Screws “>

editor by Dream 2024-10-11