Product Description

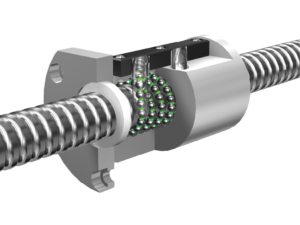

GG Series Stepped Precision Ball Screw (C3/C5)

| Table of Shaft dia. and Lead combination for Precision Ball Screw | |||||||||||||||||||||||

| Lead (mm) | |||||||||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 16 | 20 | 25 | 30 | 32 | 40 | 50 | 60 | 63 | ||

| Shaft dia (mm) | 4 | / | / | / | / | / | |||||||||||||||||

| 5 | / | / | / | ||||||||||||||||||||

| 6 | / | / | / | / | / | / | / | ||||||||||||||||

| 8 | / | / | / | / | / | / | / | / | / | / | / | ||||||||||||

| 10 | / | / | / | / | / | / | / | / | / | / | / | / | |||||||||||

| 12 | / | / | / | / | / | / | / | / | |||||||||||||||

| 13 | / | / | / | ||||||||||||||||||||

| 14 | / | / | / | / | / | ||||||||||||||||||

| 15 | / | / | / | / | |||||||||||||||||||

| 16 | / | / | / | / | / | / | / | / | |||||||||||||||

| 20 | / | / | / | / | / | / | / | / | |||||||||||||||

| 25 | / | / | / | / | / | / | / | ||||||||||||||||

| 28 | / | / | |||||||||||||||||||||

| 30 | / | / | |||||||||||||||||||||

| 32 | / | / | / | / | / | / | / | / | / | / | / | ||||||||||||

| 39 | / | / | / | ||||||||||||||||||||

| 40 | / | / | / | / | / | / | / | / | / | / | / | ||||||||||||

| 48 | / | / | |||||||||||||||||||||

| 50 | / | / | / | / | / | / | / | / | / | / | / | / | / | / | |||||||||

| 60 | / | / | |||||||||||||||||||||

| 63 | / | / | / | / | / | / | / | / | / | / | |||||||||||||

| 80 | / | / | / | / | / | / | / | ||||||||||||||||

| 100 | / | / | / | / | / | ||||||||||||||||||

| 120 | / | / | |||||||||||||||||||||

| 125 | / | / | / | / | / | / | |||||||||||||||||

| 160 | / | / | / | / | |||||||||||||||||||

| 200 | / | / | / | ||||||||||||||||||||

Accuracy class and axial clearance

Accuracy grade of GG series stepped precision ball screw are based on C3 and C5(JISB1192-3). According to accuracy grade, Axial play 0 (Preload :C3) and 0.005mm or less(C5).

Material & Surface Hardness

GG series stepped precision ball screw of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semiconductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Shaft End Shape

The shaft end shape of the GG series stepped precision ball screw has been standardized.

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What role do lead screws play in ensuring proper alignment and tightness in mechanical assemblies?

Lead screws play a crucial role in ensuring proper alignment and tightness in mechanical assemblies. They provide a reliable means of applying axial force to securely fasten components together. Here’s how lead screws contribute to alignment and tightness:

Alignment:

Lead screws aid in achieving proper alignment in mechanical assemblies through the following mechanisms:

- Linear Motion: Lead screws convert rotary motion into linear motion, allowing for controlled movement and alignment of components. By rotating the lead screw, the connected nut or threaded component moves along the screw’s axis, enabling precise positioning and alignment of the assembly.

- Thread Engagement: The mating threads of the lead screw and nut provide a positive mechanical connection. As the nut moves along the screw, the threads engage tightly, ensuring accurate alignment between the screw and the nut. This thread engagement helps maintain the desired position and alignment of components within the assembly.

- Guidance and Support: Lead screws often incorporate guidance mechanisms, such as linear bearings or sliding surfaces, to ensure smooth and accurate linear motion. These guidance systems help prevent lateral movement, minimize misalignment, and maintain the intended trajectory of the assembly, improving overall alignment.

- Positioning Accuracy: Lead screws offer precise positioning capabilities, allowing for the accurate alignment of components. The thread pitch and design, combined with the rotational input, enable controlled linear movement and positioning. This precision is critical in applications where proper alignment is essential for optimal performance and functionality.

Tightness:

Lead screws contribute to achieving tightness and secure fastening in mechanical assemblies through the following means:

- Axial Force Application: Lead screws transmit axial force to clamp or tighten components together. By rotating the lead screw, the axial force is applied through the nut or threaded component, generating a clamping action that holds the assembly tightly. This axial force helps prevent loosening, vibration, or unintended movement of the connected components.

- Self-Locking Capability: Lead screws possess a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads provides resistance to back-driving and helps maintain the tightness of the assembly. This self-locking property ensures that the assembly remains securely fastened, even in the absence of continuous power input.

- Thread Friction: The friction between the mating threads of the lead screw and nut contributes to the tightness of the assembly. When properly lubricated, the thread friction helps increase the resistance to loosening or undesired movement. By controlling the thread friction, the tightness of the assembly can be optimized to meet the specific requirements of the application.

- Preload Adjustment: Lead screws allow for preload adjustment, which is the intentional application of axial force to achieve a desired level of tightness. Preload can be applied by adjusting the initial position of the nut along the lead screw or by incorporating preload mechanisms, such as spring washers or Belleville washers. Preload optimization ensures that the assembly remains tight and secure, even under varying loads or external disturbances.

Overall, lead screws provide a reliable means of achieving proper alignment and tightness in mechanical assemblies. Their linear motion capabilities, thread engagement, guidance mechanisms, positioning accuracy, axial force application, self-locking capability, and preload adjustability all contribute to ensuring the stability, alignment, and tightness of the assembled components.

What are the signs that indicate a need for lead screw replacement or maintenance, and how can they be diagnosed?

Lead screws, like any mechanical component, may require replacement or maintenance over time due to wear, damage, or performance degradation. Recognizing the signs of potential issues and diagnosing them accurately is essential for timely intervention. Here are some common signs that indicate a need for lead screw replacement or maintenance, along with diagnostic methods:

- Increased Backlash: An increase in backlash, which is the clearance or play between the lead screw and nut, can signify wear or mechanical issues. Excessive backlash can result in decreased accuracy and precision. Diagnosis: Backlash can be measured using specialized tools, such as dial indicators or laser displacement sensors. Comparing the current backlash with the manufacturer’s specifications can help determine if maintenance or replacement is necessary.

- Unusual Noise or Vibration: Unusual noises, vibrations, or excessive mechanical resonance during operation can indicate misalignment, worn components, or inadequate lubrication. Diagnosis: Careful observation and listening during operation can help identify abnormal noise or vibration. Inspecting the lead screw for signs of wear, checking alignment, and ensuring proper lubrication can help diagnose the underlying issue.

- Reduced Accuracy or Repeatability: If a lead screw system starts exhibiting decreased accuracy or repeatability in positioning, it may indicate wear, misalignment, or damaged components. Diagnosis: Conducting precision tests or comparing the system’s actual position with the desired position can help identify any inconsistencies. Inspecting the lead screw, nut, or associated components for signs of wear or damage can provide further insights.

- Increased Friction or Sticking: If the lead screw system experiences increased friction or sticking during operation, it may indicate inadequate lubrication, contamination, or worn components. Diagnosis: Observing the smoothness of the lead screw’s movement and checking for signs of lubrication deficiency or contamination can help diagnose the issue. Cleaning the lead screw and applying appropriate lubrication may resolve minor friction-related problems.

- Visible Wear or Damage: Visual inspection of the lead screw and nut may reveal signs of wear, corrosion, or physical damage. This can include worn threads, scoring, pitting, or deformation. Diagnosis: Regular visual inspection of the lead screw system is important to identify visible signs of wear or damage. If significant wear or damage is observed, replacement or repair may be necessary.

- Inconsistent or Jerky Movement: If the lead screw system exhibits inconsistent or jerky movement instead of smooth and controlled motion, it may indicate misalignment, binding, or damaged components. Diagnosis: Careful observation of the system’s movement, checking for misalignment, and inspecting the lead screw, nut, or associated bearings for signs of binding or damage can help diagnose the issue.

It’s important to note that proper diagnosis and decision-making regarding lead screw replacement or maintenance may require the expertise of qualified technicians or engineers familiar with the specific application and system requirements. Following manufacturer guidelines, maintenance schedules, and seeking professional assistance can help ensure accurate diagnosis and appropriate actions to maintain or replace the lead screw when necessary.

Can you explain the role of a lead screw in converting rotary motion to linear motion?

A lead screw plays a crucial role in converting rotary motion into linear motion in mechanical systems. It achieves this by utilizing the helical threads on the screw and the corresponding threads on the nut. Here’s a detailed explanation of how a lead screw accomplishes the conversion:

- Helical Thread Design: A lead screw is designed with a helical thread that wraps around its cylindrical shaft. The thread is typically a continuous spiral groove with a specific pitch, which is the distance between adjacent threads. The pitch determines the linear distance the nut will travel when the lead screw makes one complete revolution.

- Matching Threaded Nut: The lead screw is paired with a nut that has threads matching those on the screw. The nut is typically fixed in place while the lead screw rotates. The nut contains internal threads that engage with the external threads of the lead screw.

- Rotary Motion: When the lead screw is rotated, either manually or by a motor-driven mechanism, the helical threads on the screw cause the nut to move linearly along the length of the screw. The direction and magnitude of the linear motion depend on the direction and speed of the screw’s rotation.

- Linear Motion: As the lead screw rotates, the engaged threads between the screw and the nut create a force that translates the rotational motion into linear motion. The helical threads on the screw push against the matching threads in the nut, causing the nut to move along the length of the screw. This results in linear displacement of the nut and any attached components.

- Precision and Control: The pitch of the lead screw determines the linear distance traveled by the nut for each revolution of the screw. By controlling the rotational motion of the lead screw, precise and controlled linear movement can be achieved. This makes lead screws suitable for applications that require accurate positioning or adjustment of components.

- Load Capacity: Lead screws can handle both axial loads (tension or compression forces) and torque. The helical threads distribute the load over a larger surface area, allowing the lead screw to support and transfer significant loads. By incorporating thrust bearings or other supporting elements, the lead screw can handle high loads while maintaining smooth and controlled linear motion.

Overall, the lead screw’s role in converting rotary motion to linear motion relies on the interaction between the helical threads of the lead screw and the matching threads of the nut. This mechanism provides a reliable and precise means to translate rotational motion into linear displacement, making lead screws a valuable component in various mechanical systems and applications.

<img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l1.webp" alt="China Hot selling CHINAMFG Hight Quality Ball Guide Ball Screw for Hydraulic Pump Parts (GG Series, Lead: 2mm, Shaft: 8mm) “><img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l2.webp" alt="China Hot selling CHINAMFG Hight Quality Ball Guide Ball Screw for Hydraulic Pump Parts (GG Series, Lead: 2mm, Shaft: 8mm) “>

editor by Dream 2024-10-24