Product Description

High Quality L 316 430 Stainless steel lead screw

Product Description:

Introduction:

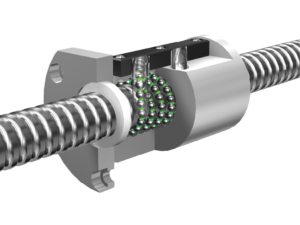

Trapezoidal lead screw is made of screw and T-nut. Its function is to turn the rotary motion into linear motion which is a future extension and development of ball screw. The significance of the development is to move into a rolling bearing from sliding action. With little frication, Trapezoidal Screws are widely used into various industrial equipment and precision instruments.

Application:

The trapezoidal screw is commonly used in instrument-level applications that require smooth, precise, clean, and maintenance-free operation. The nut is usually made of internally lubricated polymer materials. The trapezoidal screw is also used in laboratory and life science equipment, such as DNA sampling equipment, scHangZhou equipment and fluid handling equipment. Other applications include engraving, rapid prototyping, inspection and data storage devices. Alternatively, a sliding lead screw with a metal (usually copper) nut can be used for heavy-duty lifting.

We produce all types of standard or non-standard trapezoidal lead screws and nuts according to customer’s request.Detailed as following table:

| Trapezoidal Screw Material | Stainless steel | Carbon steel | Alloy steel | Alloy steel |

| Screw Nuts Material | Stainless steel | Carbon steel | POM | Bronze/Brass/Copper |

| Regular Size | TR5/6/8/10/12/14/16/18/20/22/25/28/30/32/36/40/45/50,Other sizes mades to orders | |||

| Thread Direction | Right | Left | Right and Left | |

| Manufacturing Process | Rolled Thread | Rolled Thread | ||

| Length | 1000mm/Customized Length 100mm-3000mm | |||

| End machining Customized | Provided | |||

We supply Stainless steel lead screw of various specifications and materials, and provide customized services.

Specifications:

Packing&Delivery:

Packing method: standard packaging or customized

Delivery cycle:Complete the delivery within 5-10 days after your payment.

About us:

Certificate:

We have cooperated with experienced shipping forwarders for many years, they arrange the shipment. No matter by express, by airor by sea, we will track the course of the goods all the way, to make sure goods arrive at you on time and in good condition.

Transportation and payment:

We support sea transportation, air transportation, land transportation, international express and other transportation conditions.

We support LC, TT, Western Union and other payment methods.

FAQ:

Q1. How long can make delivery?

A: For stock products,will make shipments in 2-5 days after receiving deposit or receiving T/T;

for products need new production for common materials,usually make shipments in 7-10 days;

for products need special and rare materials,usually need 15-20 days to make shipment.

Q2. Can you provide the samples?

A:Samples can be provided with samples’ charge and courier fee by the buyer’s side.

Q3: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow

up your case.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

Airline and sea shipping also optional.

For mass products, ship freight is prefered.

Q5. Can you accept customize?

A: Yes. It can be customized as per the customers’ request.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C0 |

|---|---|

| Screw Diameter: | 1-100mm |

| Flange: | Without Flange |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What role do lead screws play in ensuring proper alignment and tightness in mechanical assemblies?

Lead screws play a crucial role in ensuring proper alignment and tightness in mechanical assemblies. They provide a reliable means of applying axial force to securely fasten components together. Here’s how lead screws contribute to alignment and tightness:

Alignment:

Lead screws aid in achieving proper alignment in mechanical assemblies through the following mechanisms:

- Linear Motion: Lead screws convert rotary motion into linear motion, allowing for controlled movement and alignment of components. By rotating the lead screw, the connected nut or threaded component moves along the screw’s axis, enabling precise positioning and alignment of the assembly.

- Thread Engagement: The mating threads of the lead screw and nut provide a positive mechanical connection. As the nut moves along the screw, the threads engage tightly, ensuring accurate alignment between the screw and the nut. This thread engagement helps maintain the desired position and alignment of components within the assembly.

- Guidance and Support: Lead screws often incorporate guidance mechanisms, such as linear bearings or sliding surfaces, to ensure smooth and accurate linear motion. These guidance systems help prevent lateral movement, minimize misalignment, and maintain the intended trajectory of the assembly, improving overall alignment.

- Positioning Accuracy: Lead screws offer precise positioning capabilities, allowing for the accurate alignment of components. The thread pitch and design, combined with the rotational input, enable controlled linear movement and positioning. This precision is critical in applications where proper alignment is essential for optimal performance and functionality.

Tightness:

Lead screws contribute to achieving tightness and secure fastening in mechanical assemblies through the following means:

- Axial Force Application: Lead screws transmit axial force to clamp or tighten components together. By rotating the lead screw, the axial force is applied through the nut or threaded component, generating a clamping action that holds the assembly tightly. This axial force helps prevent loosening, vibration, or unintended movement of the connected components.

- Self-Locking Capability: Lead screws possess a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads provides resistance to back-driving and helps maintain the tightness of the assembly. This self-locking property ensures that the assembly remains securely fastened, even in the absence of continuous power input.

- Thread Friction: The friction between the mating threads of the lead screw and nut contributes to the tightness of the assembly. When properly lubricated, the thread friction helps increase the resistance to loosening or undesired movement. By controlling the thread friction, the tightness of the assembly can be optimized to meet the specific requirements of the application.

- Preload Adjustment: Lead screws allow for preload adjustment, which is the intentional application of axial force to achieve a desired level of tightness. Preload can be applied by adjusting the initial position of the nut along the lead screw or by incorporating preload mechanisms, such as spring washers or Belleville washers. Preload optimization ensures that the assembly remains tight and secure, even under varying loads or external disturbances.

Overall, lead screws provide a reliable means of achieving proper alignment and tightness in mechanical assemblies. Their linear motion capabilities, thread engagement, guidance mechanisms, positioning accuracy, axial force application, self-locking capability, and preload adjustability all contribute to ensuring the stability, alignment, and tightness of the assembled components.

Are there innovations or advancements in lead screw technology that have emerged in recent years?

In recent years, there have been notable innovations and advancements in lead screw technology aimed at improving performance, efficiency, precision, and durability. These advancements have been driven by the demand for more sophisticated machinery and automation systems. Here are some key innovations in lead screw technology that have emerged in recent years:

- Anti-Backlash Designs: Backlash, which refers to the play or clearance between the screw and nut, has been a longstanding challenge in lead screw systems. To address this issue, innovative anti-backlash designs have been developed. These designs incorporate mechanisms such as preloading systems, split nuts, or adjustable axial play to minimize or eliminate backlash, resulting in improved precision and repeatability.

- High-Efficiency Thread Profiles: Traditional lead screws often feature trapezoidal or ACME thread profiles, which can result in higher friction and lower mechanical efficiency. Recent advancements have introduced new thread profiles, such as the “triangular” or “wedge” profiles, which optimize the contact area between the screw and nut, reducing friction and improving mechanical efficiency. These high-efficiency thread profiles offer smoother operation, increased load-carrying capacity, and improved energy efficiency.

- Lead Screw Coatings and Surface Treatments: Coatings and surface treatments have been developed to enhance the durability, wear resistance, and lubrication properties of lead screws. For example, advanced coatings like Teflon, ceramic, or DLC (Diamond-Like Carbon) coatings provide low friction, reduce wear, and improve the lifespan of the lead screw. These coatings also help prevent contaminants from adhering to the surfaces, minimizing the risk of damage or performance degradation.

- Integrated Lubrication Systems: Lubrication is crucial for smooth operation and longevity of lead screws. Recent advancements have introduced integrated lubrication systems that automatically deliver a controlled amount of lubricant to the screw and nut. These systems ensure consistent and optimal lubrication, reducing friction, wear, and the need for manual lubrication maintenance. Integrated lubrication systems can be particularly beneficial in applications where access to the lead screw is limited or in environments where contamination risks are high.

- Smart and Connected Lead Screw Systems: The rise of Industry 4.0 and the Internet of Things (IoT) has led to the development of smart and connected lead screw systems. These systems feature embedded sensors, communication capabilities, and data analytics algorithms. They enable real-time monitoring of operating parameters, condition monitoring, predictive maintenance, and performance optimization. Smart lead screw systems provide valuable insights, enhance operational efficiency, and reduce downtime by enabling proactive maintenance and troubleshooting.

- Hybrid Lead Screw Technologies: Hybrid lead screw technologies combine the advantages of different types of screws, such as combining a traditional lead screw with a ball screw or roller screw elements. This fusion results in enhanced performance characteristics, such as increased load capacity, improved efficiency, reduced friction, and higher precision. Hybrid lead screws offer a cost-effective alternative to high-precision ball screws while providing superior performance compared to traditional lead screws.

These recent innovations and advancements in lead screw technology have significantly improved the performance, efficiency, precision, and durability of lead screw systems. Anti-backlash designs, high-efficiency thread profiles, advanced coatings, integrated lubrication systems, smart and connected features, and hybrid technologies have expanded the capabilities and application range of lead screws in various industries, including aerospace, automotive, robotics, and industrial automation.

Are there specific advantages to using lead screws over other linear motion systems?

Yes, there are specific advantages to using lead screws over other linear motion systems. Here are some of the advantages associated with lead screws:

- Precision and Accuracy: Lead screws offer precise and accurate linear motion control. The thread design and pitch allow for precise positioning and movement of components, making them suitable for applications that require high levels of accuracy and repeatability.

- Cost-Effectiveness: Lead screws are often more cost-effective compared to other linear motion systems, such as ball screws or linear actuators. They provide a reliable and efficient solution for converting rotary motion into linear motion at a relatively lower cost, making them a popular choice for many applications.

- High Load Capacity: Lead screws are capable of handling significant axial loads and torque. The thread engagement between the screw and nut distributes the load over a larger surface area, allowing lead screws to support and transfer substantial loads. This makes them suitable for applications that require heavy-duty performance and load-carrying capabilities.

- Self-Locking: Lead screws have a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads helps prevent back-driving and maintains the position of the load, providing stability and safety in applications where holding the position is critical.

- Simple Design and Installation: Lead screws have a relatively simple design, consisting of a screw and a nut. This simplicity makes them easier to install and maintain compared to more complex linear motion systems. Additionally, the straightforward design allows for customization and modification to meet specific application requirements.

- Efficiency: Lead screws can achieve high mechanical efficiency in converting rotary motion to linear motion. The efficiency depends on factors such as the thread design, lubrication, and preload. With proper design and lubrication, lead screws can operate with minimal friction and energy loss, ensuring efficient power transmission.

- Versatility: Lead screws can be used in a wide range of applications across various industries. They are suitable for applications that require linear motion, precise positioning, or adjustment of components. Lead screws find applications in industries such as manufacturing, automation, robotics, aerospace, medical, and more.

These advantages make lead screws a popular choice in many applications where precise linear motion control, cost-effectiveness, high load capacity, and simplicity are essential. However, it’s important to consider specific application requirements and factors such as speed, accuracy, duty cycle, and environmental conditions when selecting the appropriate linear motion system.

editor by CX 2024-02-23