Product Description

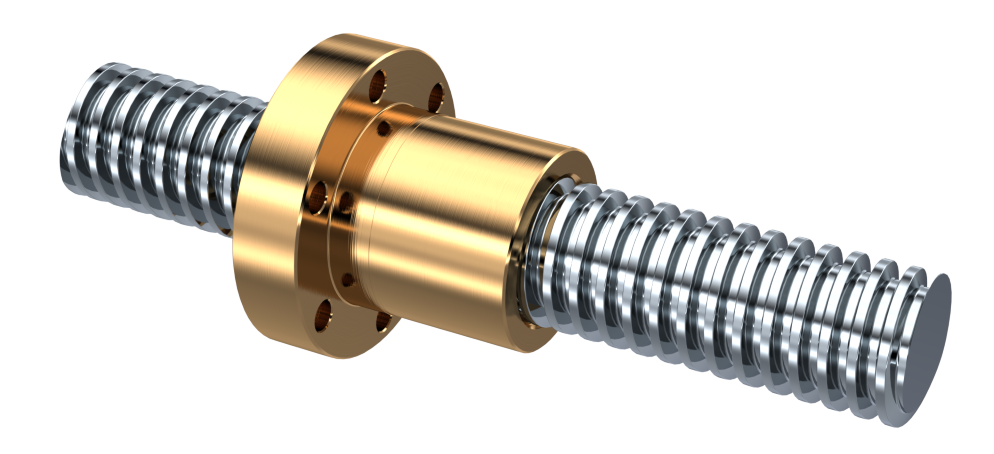

Customized CNC Lead Screw Trapezoidal Threaded Rod with Nut for 3d Printer

Product details

| Product name | Lead Screw |

| Material | carbon steel |

| Process | cnc lathing+stamping |

| Finish | Zinc plated |

| Color | Silver |

| OEM | Yes |

| Package | Carton |

| Usage | Auto spare parts |

Images

Production Flow

Inspection equipments

Package

Delivery

Shipping way

| Express | By Air | By Sea | |

| Price | High | Middle | Low |

| Weight | 50kg | 100-250kg | Above 400kg |

| Deliver time | 3-5 days | 10-15 days | 25-30 days |

Company Information

Manufacturing Workshops

Certificates

Customers

FAQ

Q1: Are you a manufacturer or trading company?

A1: We are a Factory which has 16year-manufacturer in hardware products.

Q2: Do you provide ODM/OEM service?

A2: OEM / ODM is welcome, We got a professional and creative R&D team, and customized colors are optional. From the concept to finished goods, we do all ( design, prototype reviewing, tooling and production ) in the factory.

Q3: Where is your factory located? How can I visit it?

A3: Our factory is located in HangZhou, ZheJiang , HangZhou is the Closest city to HangZhou and HangZhou, Hongkong. 1 hour from HangZhou and HangZhou by car. 1.5 hours flight from Hong Kong ( 1 hour by car+0.5 hour by boat ).

Q4: Is it possible to know how are my products going on without visiting your company?

A4: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q5: How can I get the sample? What’s the lead time?

A5: Normally will be send in 7 days. If need to open new Model, need another 10-15 days more.

Q6: What’s the lead time for mass production?

A6: 15-20 working days after down payment confirmed, can be negotiable.

Q7: How does your factory control product quality?

A7: ISO9001: 2008, ISO / TS16949 Certificated, independent quality control team with 16 inspectors in our factory. Third party certificated and factory audit accepted. Third party quality control accepted.

Q8: What about the payment terms?

A8: FOB HangZhou Port. 30% deposit by T / T, 70% before all shipment.

We offer the photo, video or even Third Party to check.

Q9: If you make poor quality goods, will you refund our fund?

A9: As a matter of fact, we wont take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.

Products Show

More information about us,please click below :

http://yubiao2018

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Stainless Steel |

|---|---|

| Type: | Pan Head |

| Groove: | Interior Angles Quartet |

| Connection: | Common Bolt |

| Head Style: | Without Head |

| Standard: | DIN, GB, ANSI, JIS |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can lead screws be customized for specific industries or machinery configurations?

Yes, lead screws can be customized to meet the specific requirements of different industries or machinery configurations. Customization allows for the adaptation of lead screws to unique applications, ensuring optimal performance and compatibility. Here’s how lead screws can be customized:

Thread Design:

The thread design of lead screws can be customized to suit specific applications. The thread profile, such as Acme, square, or buttress, can be selected based on factors such as load capacity, efficiency, backlash, and self-locking characteristics. The thread pitch can be adjusted to achieve the desired linear travel per revolution, allowing for different positioning resolutions. Custom thread designs can also be implemented to address specific requirements or constraints of the machinery configuration.

Materials and Coatings:

The choice of materials for lead screws can be customized based on the application’s environmental conditions and performance requirements. Different materials, such as stainless steel, carbon steel, or alloys, can be selected for their mechanical properties, corrosion resistance, or temperature resistance. Additionally, lead screws can be coated or treated with specialized coatings, such as Teflon or ceramic coatings, to reduce friction, improve wear resistance, or enhance lubrication properties.

Size and Dimensions:

The size and dimensions of lead screws can be customized to fit specific machinery configurations or space constraints. This includes variations in length, diameter, and thread length to ensure proper fit and integration within the machinery or system. Customization of lead screw dimensions allows for efficient utilization of available space and compatibility with existing components or mounting mechanisms.

End Machining:

Lead screws can be customized with different types of end machining to facilitate their connection to other components or power sources. This may involve the addition of keyways, flats, or other features to enable coupling with drive mechanisms, such as motors or handwheels. Customized end machining ensures proper alignment, torque transmission, and ease of installation within the specific machinery configuration.

Accessories and Attachments:

Customization of lead screws can also involve the addition of accessories or attachments to enhance their functionality or compatibility with specific industries or machinery configurations. This may include the inclusion of anti-backlash nuts, thrust bearings, lubrication systems, or wipers. These accessories and attachments can improve precision, reduce wear, increase load capacity, or address specific application requirements.

By offering customization options, lead screw manufacturers can cater to the diverse needs of different industries and machinery configurations. Customized lead screws ensure that the linear motion system is optimized for performance, efficiency, and compatibility, resulting in improved overall functionality and reliability.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

How does a lead screw differ from other types of screws in terms of design and functionality?

A lead screw differs from other types of screws in terms of its design and functionality. Here’s a detailed explanation of the distinctions between lead screws and other screw types:

- Thread Design: Lead screws have a helical thread design, meaning the threads wrap around the screw’s cylindrical shaft in a continuous spiral. This helical thread allows for the conversion of rotary motion into linear motion. In contrast, other types of screws, such as machine screws or wood screws, typically have a straight or tapered thread design suited for fastening or joining applications.

- Linear Motion Conversion: The primary function of a lead screw is to convert rotary motion into linear motion or vice versa. It achieves this by utilizing the engagement between the helical threads on the screw and the matching threads on the nut. This capability makes lead screws suitable for applications requiring precise positioning, actuation, or adjustment of components along a linear path. In contrast, other screws are primarily used for fastening, joining, or securing objects together.

- Precision and Control: Lead screws offer precise control over linear movement due to their thread pitch and the ability to rotate the screw with precision. The pitch determines the linear distance the nut will travel for each revolution of the screw. This feature makes lead screws well-suited for applications that demand accurate positioning or adjustment. In contrast, other screws are not designed with the same level of precision or control over linear motion.

- Load Handling: Lead screws are designed to handle both axial loads (tension or compression forces) and torque. The helical threads and the engagement between the screw and nut distribute the load over a larger surface area, allowing lead screws to support and transfer significant loads. Other screw types, such as machine screws or wood screws, are primarily used for fastening and may not have the same load-bearing capabilities as lead screws.

- Applications: Lead screws find applications in various mechanical systems that require precise linear motion, such as CNC machines, 3D printers, robotic systems, and adjustable mechanisms. They are commonly used for positioning, actuation, or adjustment purposes. Conversely, other types of screws serve different purposes, such as machine screws used for fastening components together, wood screws for joining wooden materials, or self-tapping screws for creating threads in materials like metal or plastic.

Overall, the key differences between lead screws and other types of screws lie in their thread design, their ability to convert rotary motion to linear motion, the precision and control they offer, their load-handling capabilities, and the specific applications they are designed for. Understanding these distinctions is essential when selecting the appropriate screw type for a particular mechanical application.

editor by CX 2024-03-11