Product Description

Product Description:

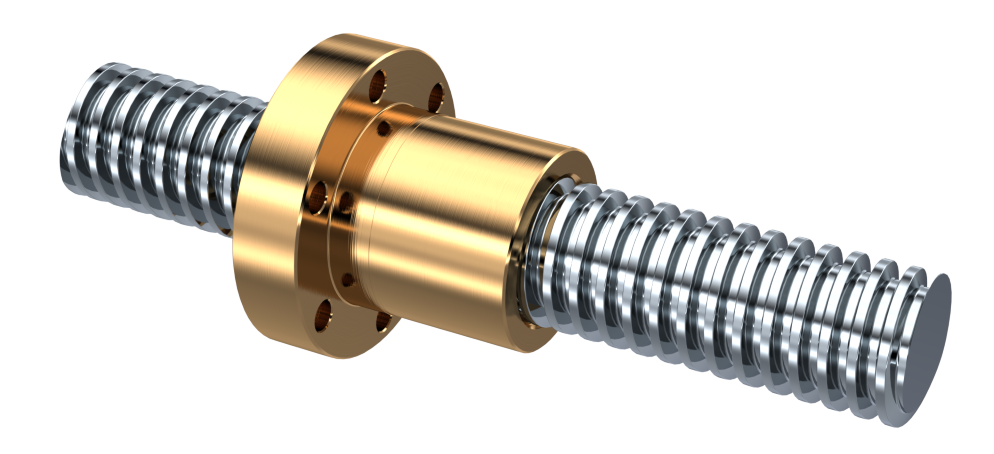

Our Factory Direct Stainless Steel Lead Screw is made from high-quality SS310, SS316, and SS304. It can be customized to any size you need. Perfect for various applications.

ZheJiang Ruixin Metal Products Co., Ltd. offers a wide range of stainless steel bars in various specifications and materials. Our stainless steel bars can be customized to meet your specific requirements. Choose from our selection of 201, 304, 316, and 430 stainless steel lead screws. Our lead screws are available in different sizes to suit your needs. Trust us for high-quality stainless steel products.

Specification:

|

Standard |

ASTM A479,ASTM A276,ASTM A484, ASTM A582, |

||

|

Material |

301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202 |

||

|

Specifications |

Round bar |

Diameter:1~500mm |

|

|

Angle bar |

Size: 0.5mm*4mm*4mm~20mm*400mm*400mm |

||

|

Flat bar |

Thickness |

0.3~200mm |

|

|

Width |

1~2500mm |

||

|

Square bar |

Size: 1mm*1mm~800mm*800mm |

||

|

Length |

2m, 5.8m, 6m, or as required. |

||

|

Surface |

Black, peeled, polishing, bright, sand blast, hair line, etc. |

||

|

Price Term |

Ex-work, FOB, CFR, CIF, etc. |

||

|

Export to |

Singapore, Canada, Indonesia, Korea, USA, UK, Thailand, Peru, Saudi Arabia, |

||

|

Delivery Time |

Standard size is in stock,prompt delivery or as order’s quantity. |

||

|

Package |

Export standard package, bundled or be required. |

||

Packing&Delivery:

Packing Method:

Our products are carefully packaged to ensure their safe delivery to you. We offer a variety of packing options to suit your needs, including standard seaworthy cartons, wooden cartons with pallets, waterproof cartons, or customized packaging. Whatever option you choose, rest assured that your order will be protected during transit.

Delivery Cycle:

We understand that you’re eager to receive your order, and we strive to get it to you as quickly as possible. Once your payment is received, we will complete the delivery within 5-10 days. This way, you won’t have to wait long to start enjoying your new stainless steel lead screw.

About Us:

Welcome to ZheJiang Ruixin Metal Products Co., Ltd.! We are a trusted company specializing in the production of high-quality stainless steel lead screws. Our factory direct stainless steel lead screws can be customized to meet your specific size requirements. With our extensive range of products and our commitment to customer satisfaction, we are confident that you will find the perfect lead screw for your needs.

Our stainless steel lead screws are made from top-grade materials, ensuring their durability and reliability. They are available in various sizes, including 0.2-200mm or customized options. Whether you need a 304 stainless steel lead screw, a 316 stainless steel lead screw, or any other type, we have you covered.

Our lead screws are designed to provide smooth and precise linear motion. They are perfect for applications that require accurate positioning, such as in machinery, robotics, and automation systems. With their excellent corrosion resistance, our stainless steel lead screws are built to withstand harsh environments and ensure long-lasting performance.

At ZheJiang Ruixin Metal Products Co., Ltd., we take pride in our exceptional product quality and customer service. We are dedicated to meeting your needs and exceeding your expectations. So why wait? Place your order today and experience the reliability and precision of our stainless steel lead screws.

Certificate:

Company Name: ZheJiang Ruixin Metal Products Co., Ltd.

Product Name: Factory Direct Stainless Steel Lead Screw

Keywords: Stainless Steel Lead Screw, 304 Stainless Steel, 316 Stainless Steel, 430 Stainless Steel, Customizable Size

Attributes: Type: Other, Transport Packaging: Wooden Pallet, Specification: 0.2-200mm or Customized

Description: This Factory Direct Stainless Steel Lead Screw from ZheJiang Ruixin Metal Products Co., Ltd. is made of high-quality 304, 316, and 430 stainless steel. It is available in various sizes and can be customized to meet your specific needs. With its durable construction and precise design, this lead screw is perfect for a wide range of applications. It comes with a wooden pallet for secure transportation and is available in a specification range of 0.2-200mm or can be customized to your requirements. Trust in the quality and reliability of this stainless steel lead screw for your industrial needs.

Dear English-speaking natives,

We are thrilled to share that we have been working closely with experienced shipping forwarders for many years. They are experts in their field and will handle all the logistics of your shipment. Whether you choose express, air, or sea transportation, we will personally track your goods every step of the way. Our goal is to ensure that your order arrives on time and in perfect condition.

Now, let’s talk about transportation and payment options. We offer a variety of convenient methods to suit your needs. You can choose the most suitable option for you, and we will make sure the process is smooth and hassle-free.

At ZheJiang Ruixin Metal Products Co., Ltd., we take pride in offering high-quality products. One of our popular items is the Factory Direct Stainless Steel Lead Screw. This lead screw can be customized to your desired size, making it a versatile option for various applications.

Our stainless steel lead screw is made from top-grade materials, ensuring durability and longevity. It is available in different types, including 304, 310, 321, 316, and more. The lead screw is crafted with precision, guaranteeing smooth and efficient performance.

When it comes to transportation and packaging, we take extra care to protect your order. Each lead screw is carefully packaged on a wooden pallet, ensuring its safety during transit. We understand the importance of delivering your goods in pristine condition, and we go above and beyond to make it happen.

The specifications of our stainless steel lead screw range from 0.2mm to 200mm, and we also offer customized options. This allows you to find the perfect fit for your specific requirements. No matter the size or specifications you choose, you can trust that our lead screw will meet your expectations.

In summary, ZheJiang Ruixin Metal Products Co., Ltd. is your reliable source for high-quality stainless steel lead screws. With our experienced shipping forwarders, we guarantee a smooth and timely delivery. Choose us for your lead screw needs, and experience the difference in quality and service.

Thank you for considering our products. We look CHINAMFG to serving you soon!

Best regards,

[Your Name]

ZheJiang Ruixin Metal Products Co., Ltd.

We offer a wide range of transportation options including sea, air, land, and international express. Our stainless steel lead screw, available in various sizes, is a high-quality product from ZheJiang Ruixin Metal Products Co., Ltd. Customize your order to meet your specific needs.

We are thrilled to offer a variety of payment methods to make your shopping experience as convenient as possible. You can choose from LC, TT, Western Union, and more!

Now, let’s dive into some frequently asked questions:

Q1. How long does it take for delivery?

A: If the product is in stock, we will ship it within 2-5 days after receiving your deposit or T/T. For products that require new production with common materials, we usually ship within 7-10 days. And for products that require special and rare materials, the shipment may take around 15-20 days.

Q2. Can you provide samples?

A: Absolutely! We can provide samples, but please note that there will be a charge for the samples and the courier fee will be covered by the buyer.

Q3: Can we visit your factory?

A: Of course! We would be delighted to have you visit our factory. Once we have your schedule, our professional sales team will make sure to follow up with your case.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship our products using reliable services like DHL, UPS, FedEx, or ***. Typically, it takes around 3-5 days for the goods to arrive. If you prefer, we can also arrange airline or sea shipping for you. For mass products, shipping by freight is preferred.

Q5. Can you customize the products?

A: Absolutely! We are more than happy to customize the products according to your specific requests.

Product Description:

Introducing our Factory Direct Stainless Steel Lead Screw! This lead screw is made from high-quality stainless steel and can be customized to your desired size. It is perfect for various applications and offers exceptional durability and performance.

Key Features:

– Made from premium stainless steel for superior strength and corrosion resistance.

– Can be customized to meet your specific size requirements.

– Suitable for a wide range of applications.

– Provides excellent durability and long-lasting performance.

Product Specifications:

– Type: Other

– Transportation Packaging: Wooden Pallet

– Specifications: 0.2-200mm or customized

Don’t miss out on this fantastic stainless steel lead screw! Place your order now and experience the quality and reliability that ZheJiang Ruixin Metal Products Co., Ltd. is known for.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Stainless Steel Lead Screw |

|---|---|

| Length: | 4m 6m |

| Diameter: | 1~500mm |

| Samples: |

US$ 1.9/kg

1 kg(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the design of lead screws impact their performance in different environments?

The design of lead screws plays a crucial role in determining their performance in different environments. Lead screws are mechanical devices used to convert rotational motion into linear motion. They consist of a screw (also known as the lead screw or power screw) and a nut that engages with the screw’s threads. The performance of lead screws can be influenced by various design factors, including the thread profile, lead angle, material selection, and lubrication.

Thread Profile: The thread profile of a lead screw refers to the shape of the threads on the screw and nut. Common thread profiles include square, Acme, and ball screw. The choice of thread profile affects the efficiency, backlash, and load-carrying capacity of the lead screw. For example, ball screws generally offer higher efficiency and lower backlash compared to square or Acme threads, making them suitable for applications requiring high precision and efficiency.

Lead Angle: The lead angle of a lead screw is the angle between the helix and the axis of the screw. It determines the linear distance traveled by the nut for each revolution of the screw. Lead angle influences the mechanical advantage, speed, and load-carrying capacity of the lead screw. Steeper lead angles provide higher mechanical advantage but may reduce the speed and load capacity. Shallower lead angles, on the other hand, offer higher speed but lower mechanical advantage.

Material Selection: The choice of materials for lead screws depends on the specific environmental conditions and application requirements. Factors such as mechanical strength, wear resistance, corrosion resistance, and temperature resistance need to be considered. Common materials for lead screws include stainless steel, carbon steel, and bronze. Stainless steel is often preferred for its corrosion resistance, while bronze may be chosen for its self-lubricating properties.

Lubrication: Proper lubrication is essential for the smooth operation and longevity of lead screws. Lubricants reduce friction and wear between the screw and nut, improving efficiency and reducing the chances of seizing or galling. The selection of lubricants depends on the operating conditions, such as temperature, speed, and load. For high-temperature environments, specialized high-temperature lubricants may be required.

In different environments, the design considerations for lead screws may vary. For example:

- In high-temperature environments, the selection of materials with high-temperature resistance becomes critical to prevent premature failure or deformation of the lead screw.

- In corrosive environments, materials with good corrosion resistance, such as stainless steel or specialized coatings, should be chosen to protect the lead screw from chemical degradation.

- In applications where precision is crucial, such as CNC machines or robotics, lead screws with low backlash and high efficiency, such as ball screws, are often preferred.

In summary, the design of lead screws, including thread profile, lead angle, material selection, and lubrication, significantly impacts their performance in different environments. It is important to consider the specific requirements of the application and environmental conditions to choose the most suitable lead screw design for optimal performance and longevity.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

Can you describe the various types and configurations of lead screws available in the market?

Lead screws are available in various types and configurations to suit different applications and requirements. Here’s an overview of the common types and configurations of lead screws found in the market:

- Acme Lead Screws: Acme lead screws are one of the most widely used types. They have a trapezoidal thread profile with a 29-degree thread angle. Acme screws are known for their strength, durability, and high load-carrying capacity. They offer efficient linear motion conversion and are commonly used in applications that require heavy-duty and high-load capabilities.

- Ball Screws: Ball screws are precision lead screws that incorporate ball bearings between the screw and nut. The ball bearings reduce friction, allowing for smoother and more efficient linear motion. Ball screws offer high accuracy, low backlash, and excellent repeatability. They are commonly used in applications that require high precision, such as CNC machines, robotics, and semiconductor manufacturing equipment.

- Stub Acme Screws: Stub Acme screws are similar to Acme screws but have a shallower thread depth. They offer higher efficiency and smoother operation compared to Acme screws. Stub Acme screws are commonly used in applications where space is limited or when a lighter load capacity is required.

- Buttress Screws: Buttress screws have a thread profile with one flank at a 45-degree angle and the other flank perpendicular to the screw axis. This design provides high load-carrying capacity in one direction while allowing for easy movement in the opposite direction. Buttress screws are commonly used in applications that require the transmission of heavy axial loads in a single direction, such as presses or jacks.

- Multiple-Start Screws: Multiple-start screws have two or more threads wrapped around the screw shaft. This design allows for faster linear travel per revolution compared to single-start screws. Multiple-start screws are used in applications where higher linear speeds or quick linear positioning is required.

- Thread Forms: Apart from the specific types mentioned above, lead screws can also come in different thread forms to suit specific applications. Some common thread forms include square threads, triangular threads, and rounded threads. These thread forms offer variations in load-carrying capacity, efficiency, backlash, and cost, providing options to meet specific application requirements.

- Lead Screw Configurations: Lead screws can be found in various configurations depending on the specific application. Some configurations include:

- – Standard Lead Screws: These are the most common configurations with a cylindrical shaft and threads along its length.

- – Flanged Lead Screws: These lead screws have a flange at one or both ends, providing support and alignment in certain applications.

- – Anti-Backlash Lead Screws: These lead screws incorporate mechanisms to minimize or eliminate backlash, providing more precise linear motion control.

- – Customized Lead Screws: Lead screws can be customized to meet specific application requirements, such as specific dimensions, thread pitch, end machining, or material selection.

These are some of the common types and configurations of lead screws available in the market. The selection of the appropriate lead screw type depends on factors such as load requirements, precision needs, speed, backlash tolerance, and specific application constraints.

editor by CX 2024-02-27