Product Description

Product Description

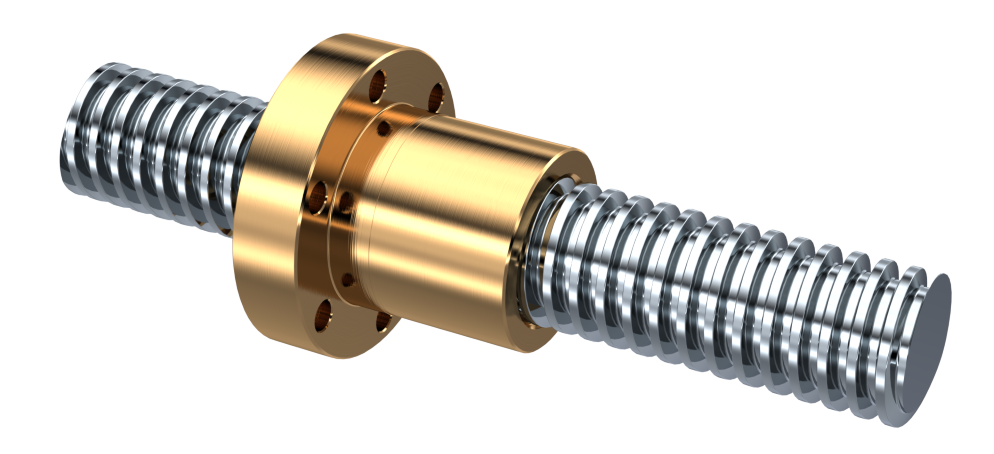

| Name | Stainless Steel Lead Screw T10*2 100mm 200mm lead screw rod with brass nut |

| Material | Chrome steel,Stainless steel Steel |

| Features | High reliability, Smooth operation, High rigidity and preload, High durability |

| Diameter | 8mm,10mm,12mm,14mm,16mm,18mm,20mm |

Product Parameters

Packaging & Shipping

Packaging Details: 1)Sample order packing by paper carton for saving freight charge;

2)bulk order sent by sea will be packed by film and wooden carton.

3) as customer’s requirements.

Delivery Detail: within 5-15 days against payment

Company Profile

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is located at Xihu (West Lake) Dis. Industrial Zone Xihu (West Lake) Dis. County which is the beautiful Xihu (West Lake) Dis. Water City and the famous painting and calligraphy village.The south is 308 National Road, the west is the 105 National Highway, the north is HangZhou-HangZhou Highway, the position is very superior. It is 1 of the biggest linear guide manufacturers in China.

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production.

Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters, production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons. We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products, and we pack them very well to make sure the goods in well protection.

5.Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products, it is really too hard to send all of catalogue and price list for you. Please inform us the style you interested, we can offer the pricelist for your reference.

6.Q:There are a lot of companies which export bearings, why do you choose us?

A: As we are a genuine linear guide supplier since 2011.and we are really factory, you need not pay the profit for middlemen. so we can offer you the lowest and competitive price.

Our Advantages

1. Our Team:

We have experienced and qualified team of marketing and sales representatives to serve our valued customers with the finest products and unsurpassed service.And have professional engineers team to assessment and development the new precision products,and make the OEM customized more easily,experienced QC team to test the products quaity ensure the goods quality before delivery out.

2. Our products:

Quality is the life .We use only the best quality material to ensure the precision of our

Product.All products we sold out are strictly selected and tested by our QC department.

3. Payment:

We accept payment via T/T (Bank transfer), Western Union.

4. Shipping method:

Including DHL, UPS, TNT, FEDEX,EMS, Airfreight and by Sea,as customer required.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Screw Diameter: | 11-20mm |

| Flange: | With Flange |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide examples of products or machinery that use lead screws for precise positioning?

Lead screws are widely utilized in various products and machinery that require precise positioning. Here are some examples of products and machinery that commonly use lead screws for precise positioning:

- CNC Machines: Computer numerical control (CNC) machines, including CNC mills, lathes, and routers, use lead screws to precisely position the cutting tools or workpieces. Lead screws enable accurate and repeatable movement in the linear motion systems of these machines, allowing for precise machining operations.

- 3D Printers: Lead screws are extensively used in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material, resulting in high-quality 3D prints.

- Robotics: Lead screws are integral to robotic systems that require precise positioning. They are used in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws provide accurate and controlled linear motion in robot joints, allowing for precise and coordinated movements in industrial, medical, and research robotics.

- Medical Imaging Systems: Lead screws are employed in medical imaging systems, such as computed tomography (CT) scanners and magnetic resonance imaging (MRI) machines, to precisely position the patient bed or gantry. This precise positioning is crucial for accurate imaging and diagnosis.

- Laboratory Automation Equipment: Lead screws are used in laboratory automation equipment, such as liquid handling robots and sample handling systems, for precise positioning and movement of samples, reagents, and labware. They ensure accurate and repeatable positioning required for various laboratory processes.

- Semiconductor Manufacturing Equipment: Lead screws are utilized in semiconductor manufacturing equipment, including wafer handling systems and lithography machines. They provide precise positioning and movement of wafers, masks, and other components critical for semiconductor fabrication processes.

- Camera Sliders: Lead screws are employed in camera sliders used in photography and videography applications. They enable smooth and precise linear motion of the camera along the slider, allowing for controlled tracking shots and precise camera positioning.

- Telescopes and Astronomy Equipment: Lead screws are utilized in telescopes and other astronomy equipment to precisely position optical components and achieve accurate tracking of celestial objects. They enable fine adjustments and precise pointing of telescopes for astronomical observations.

- Industrial Inspection Systems: Lead screws are used in industrial inspection systems, such as coordinate measuring machines (CMMs) and optical inspection systems, for precise movement and positioning of the inspection probes or cameras. This ensures accurate measurement and inspection of manufactured components.

These are just a few examples of the products and machinery that utilize lead screws for precise positioning. The versatility, accuracy, and reliability of lead screws make them a preferred choice in applications that require controlled linear motion and precise positioning of components.

How does the choice of lead screws affect the overall performance and reliability of linear motion systems?

The choice of lead screws has a significant impact on the overall performance and reliability of linear motion systems. Different types of lead screws offer distinct characteristics and capabilities that influence factors such as accuracy, load capacity, speed, efficiency, backlash, and durability. Here are some key ways in which the choice of lead screws affects the performance and reliability of linear motion systems:

- Accuracy and Precision: The selection of an appropriate lead screw type can directly impact the accuracy and precision of linear motion systems. Lead screws with fine thread pitches or multiple starts provide higher resolution and finer positioning capabilities, resulting in improved accuracy. Choosing a lead screw with low backlash and minimal axial play helps maintain precise motion control and repeatability.

- Load Capacity: Different lead screw designs have varying load-carrying capacities. Factors such as the diameter, pitch, material, and thread type influence the ability of a lead screw to handle axial loads. Selecting a lead screw with sufficient load capacity ensures the system can handle the required loads without compromising performance or risking premature failure.

- Speed and Efficiency: Lead screw selection affects the speed and efficiency of linear motion systems. Coarser thread pitches enable faster linear speeds, making them suitable for applications that require rapid movement. However, finer thread pitches offer increased mechanical advantage and torque conversion efficiency, making them preferable for systems requiring higher force output.

- Backlash and Repeatability: Backlash, the clearance between the lead screw and nut, can impact the accuracy and repeatability of linear motion systems. The choice of lead screw influences the amount of backlash present. Lead screws with low backlash or anti-backlash mechanisms minimize positioning errors and ensure consistent repeatability, enhancing system performance and reliability.

- Lubrication and Maintenance: Different lead screw materials and designs require specific lubrication and maintenance practices to ensure optimal performance and longevity. Some lead screws may require periodic lubrication, while others may be self-lubricating or require minimal maintenance. Choosing a lead screw that aligns with the maintenance capabilities and requirements of the system simplifies upkeep and reduces the risk of premature wear or failure.

- Environmental Considerations: The choice of lead screws should also take into account the environmental conditions in which the linear motion system will operate. Factors such as temperature, humidity, exposure to contaminants, or corrosive agents can impact the performance and reliability of lead screws. Selecting lead screws with appropriate materials, surface treatments, or protective coatings ensures compatibility with the intended operating environment.

It is crucial to carefully assess the specific requirements of the linear motion system and consider factors such as load capacity, accuracy, speed, backlash, maintenance, and environmental conditions when choosing a lead screw. Consulting with manufacturers, engineers, or industry experts can provide valuable insights and guidance to select the most suitable lead screw for achieving optimal performance, reliability, and longevity in a given application.

Are there specific advantages to using lead screws over other linear motion systems?

Yes, there are specific advantages to using lead screws over other linear motion systems. Here are some of the advantages associated with lead screws:

- Precision and Accuracy: Lead screws offer precise and accurate linear motion control. The thread design and pitch allow for precise positioning and movement of components, making them suitable for applications that require high levels of accuracy and repeatability.

- Cost-Effectiveness: Lead screws are often more cost-effective compared to other linear motion systems, such as ball screws or linear actuators. They provide a reliable and efficient solution for converting rotary motion into linear motion at a relatively lower cost, making them a popular choice for many applications.

- High Load Capacity: Lead screws are capable of handling significant axial loads and torque. The thread engagement between the screw and nut distributes the load over a larger surface area, allowing lead screws to support and transfer substantial loads. This makes them suitable for applications that require heavy-duty performance and load-carrying capabilities.

- Self-Locking: Lead screws have a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads helps prevent back-driving and maintains the position of the load, providing stability and safety in applications where holding the position is critical.

- Simple Design and Installation: Lead screws have a relatively simple design, consisting of a screw and a nut. This simplicity makes them easier to install and maintain compared to more complex linear motion systems. Additionally, the straightforward design allows for customization and modification to meet specific application requirements.

- Efficiency: Lead screws can achieve high mechanical efficiency in converting rotary motion to linear motion. The efficiency depends on factors such as the thread design, lubrication, and preload. With proper design and lubrication, lead screws can operate with minimal friction and energy loss, ensuring efficient power transmission.

- Versatility: Lead screws can be used in a wide range of applications across various industries. They are suitable for applications that require linear motion, precise positioning, or adjustment of components. Lead screws find applications in industries such as manufacturing, automation, robotics, aerospace, medical, and more.

These advantages make lead screws a popular choice in many applications where precise linear motion control, cost-effectiveness, high load capacity, and simplicity are essential. However, it’s important to consider specific application requirements and factors such as speed, accuracy, duty cycle, and environmental conditions when selecting the appropriate linear motion system.

editor by Dream 2024-04-30