Product Description

Product Description

China manufacture single thread countersunk head chipboard screw

1. Surface Treatment for the chipboard screw: white, yellow zinc plated

2. Material: C1571A steel hardend

3. Head type: countersunk head, CSK head, or double countersunk head

4. Drive type: pozi, philips,square, torx drive.

5. Point type: Sharp point

6. Thread type: single thread for wood

6. Diameter: 3.5mm, 4.0mm, 4.5mm, 5.0mm, 6mm

7. Length: from 13mm to 150mm, 1/2″ to 6″.

8. Package: Small plain box (white or brown), color print box and carton, Bulk Cartons (with big polybag), Bulk bag.

9. Mainly used for fixing and connecting chipboard.

10. Features: chipboard screw, pozi, phillips, torx or square drive, CSK head, single thread or fine thread, white, yellow zinc plated.

Detailed Photos

Certifications

CE certification

Packaging & Shipping

Company Profile

ZheZheJiang nruifeng Technology Co., Ltd., was established in 2008 and its business covers fastener design, manufacturing and export. We have 3 production bases, with a total area of 16,000 square meters. Our main products include drywall screws, chipboard screws, self-drilling screws and self-tapping screws. We can also provide other fasteners, like nails, staples, blind rivets, anchors, bolts and nuts.

We have 280 sets of automatic production equipment, including wire drawing machines, cold-heading machines, thread rolling machines, tailing machines and heat-treatment lines. We are your one-stop manufacturer from raw material to final products. Our annual production capacity reaches up to 30,000 tons, 70% of which are exported to different countries and regions.

ZheZheJiang nruifeng Technology Co., Ltd. has been in the fastener industry for 1 years and we can customize all kinds of products per your requirements. We have an established management system and quality control procedure. Excellent quality, competitive price and timely delivery are the pillars of the company’s foundation. Win-win and long-term cooperation are our final goals when dealing with different clients.

Our Advantages

1. We are the integreted company the business covers screw design, manufacturing and export.

2. We have 260 sets of automatic production equipment, including wire drawing machines, cold-heading machines, thread rolling machines, tailing machines and heat-treatment lines. We are your one-stop manufacturer from raw material to final products.

3. Advanced management system and quality control system to guarantee the best quality.

4. Attractive price due to the near the steel plant and ZheJiang sea port.

5. Welcom the customize the products, all parameter will be following your demand.

FAQ

Q: You are a manufacturing company or trading company?

A: We are screws and fastener manufacturing in ZheJiang city of china.

Q: Wonder if you accept small orders?

A: Do not worry. Please feel free to contact us, in order to give our clients more convenience ,we accept small order.

Q: Can we print our the package with own logo ?

A: Yes, we can make it according to your request.

Q: Can we provide the sample ?

A: Yes, the sample will be free to the customer, but the Express fee will be paid from you.

Q: Can you customized the head mark?

A: Yes, welcome customized, all products as your demand.

Q: How long is your delivery time?

A: Generally it is 20-30 days accoding to the order quantity, we need time the prepare the raw material and dies accoding the order.

Q: What is your payment term?

A: Generally, 30% T/T in advance ,balance payment before shippment.

Others products

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

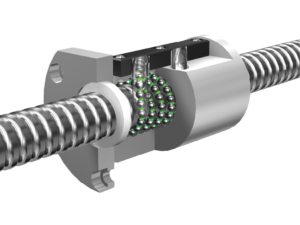

What role do lead screws play in ensuring proper alignment and tightness in mechanical assemblies?

Lead screws play a crucial role in ensuring proper alignment and tightness in mechanical assemblies. They provide a reliable means of applying axial force to securely fasten components together. Here’s how lead screws contribute to alignment and tightness:

Alignment:

Lead screws aid in achieving proper alignment in mechanical assemblies through the following mechanisms:

- Linear Motion: Lead screws convert rotary motion into linear motion, allowing for controlled movement and alignment of components. By rotating the lead screw, the connected nut or threaded component moves along the screw’s axis, enabling precise positioning and alignment of the assembly.

- Thread Engagement: The mating threads of the lead screw and nut provide a positive mechanical connection. As the nut moves along the screw, the threads engage tightly, ensuring accurate alignment between the screw and the nut. This thread engagement helps maintain the desired position and alignment of components within the assembly.

- Guidance and Support: Lead screws often incorporate guidance mechanisms, such as linear bearings or sliding surfaces, to ensure smooth and accurate linear motion. These guidance systems help prevent lateral movement, minimize misalignment, and maintain the intended trajectory of the assembly, improving overall alignment.

- Positioning Accuracy: Lead screws offer precise positioning capabilities, allowing for the accurate alignment of components. The thread pitch and design, combined with the rotational input, enable controlled linear movement and positioning. This precision is critical in applications where proper alignment is essential for optimal performance and functionality.

Tightness:

Lead screws contribute to achieving tightness and secure fastening in mechanical assemblies through the following means:

- Axial Force Application: Lead screws transmit axial force to clamp or tighten components together. By rotating the lead screw, the axial force is applied through the nut or threaded component, generating a clamping action that holds the assembly tightly. This axial force helps prevent loosening, vibration, or unintended movement of the connected components.

- Self-Locking Capability: Lead screws possess a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads provides resistance to back-driving and helps maintain the tightness of the assembly. This self-locking property ensures that the assembly remains securely fastened, even in the absence of continuous power input.

- Thread Friction: The friction between the mating threads of the lead screw and nut contributes to the tightness of the assembly. When properly lubricated, the thread friction helps increase the resistance to loosening or undesired movement. By controlling the thread friction, the tightness of the assembly can be optimized to meet the specific requirements of the application.

- Preload Adjustment: Lead screws allow for preload adjustment, which is the intentional application of axial force to achieve a desired level of tightness. Preload can be applied by adjusting the initial position of the nut along the lead screw or by incorporating preload mechanisms, such as spring washers or Belleville washers. Preload optimization ensures that the assembly remains tight and secure, even under varying loads or external disturbances.

Overall, lead screws provide a reliable means of achieving proper alignment and tightness in mechanical assemblies. Their linear motion capabilities, thread engagement, guidance mechanisms, positioning accuracy, axial force application, self-locking capability, and preload adjustability all contribute to ensuring the stability, alignment, and tightness of the assembled components.

How do electronic or computer-controlled components integrate with lead screws in modern applications?

In modern applications, electronic or computer-controlled components play a crucial role in integrating with lead screws to enhance functionality, precision, and automation. These components enable advanced control, monitoring, and feedback capabilities, allowing for more efficient and accurate operation of systems incorporating lead screws. Here are some ways electronic or computer-controlled components integrate with lead screws in modern applications:

- Position Control: Electronic control systems can precisely control the position of the lead screw by monitoring and adjusting the rotational movement of the motor driving the screw. Position feedback sensors, such as encoders or linear scales, provide real-time information about the screw’s position, allowing the control system to accurately position the load. This integration enables precise positioning and highly repeatable motion control in applications such as CNC machinery, 3D printers, or robotic systems.

- Speed and Velocity Control: Electronic control systems can regulate the speed and velocity of the lead screw by controlling the motor’s rotational speed. By adjusting the motor speed, the control system can achieve specific linear speeds or velocity profiles along the length of the lead screw. This integration is particularly useful in applications where controlled acceleration, deceleration, or dynamic speed changes are required, such as automated manufacturing processes or motion control systems.

- Force and Torque Control: In some applications, it is necessary to control the force or torque applied by the lead screw. Electronic control systems can monitor and adjust the motor’s current or voltage to regulate the applied force or torque. This integration allows for precise force control, load balancing, or torque limiting in applications such as material testing machines, automated assembly systems, or lifting mechanisms.

- Automation and Synchronization: Electronic or computer-controlled components facilitate the automation and synchronization of multiple lead screws or other mechanical components. Through centralized control, these components can coordinate the movements of multiple lead screws, ensuring precise and synchronized motion. This integration is commonly used in complex systems with multiple axes of motion, such as multi-axis CNC machines or robotic systems.

- Monitoring and Diagnostics: Electronic control systems can monitor the operating parameters of lead screws, such as temperature, vibration, or load conditions. By integrating sensors and monitoring algorithms, the control system can detect abnormal conditions, provide real-time feedback, and trigger appropriate actions, such as alerting maintenance personnel or implementing protective measures. This integration enhances system reliability, prevents failures, and enables predictive maintenance in applications where lead screw performance is critical.

- Human-Machine Interface (HMI): Electronic or computer-controlled components often provide a user interface through which operators can interact with the lead screw system. HMIs allow operators to input commands, monitor system status, and receive feedback. This integration simplifies system operation, enables parameter adjustments, and facilitates troubleshooting or diagnostics.

In summary, electronic or computer-controlled components play a vital role in integrating with lead screws in modern applications. Position control, speed and velocity control, force and torque control, automation and synchronization, monitoring and diagnostics, and human-machine interface capabilities enhance the functionality, precision, and automation of systems incorporating lead screws. This integration enables advanced control, improved performance, and enhanced operational capabilities in various industries and applications.

Are there specific advantages to using lead screws over other linear motion systems?

Yes, there are specific advantages to using lead screws over other linear motion systems. Here are some of the advantages associated with lead screws:

- Precision and Accuracy: Lead screws offer precise and accurate linear motion control. The thread design and pitch allow for precise positioning and movement of components, making them suitable for applications that require high levels of accuracy and repeatability.

- Cost-Effectiveness: Lead screws are often more cost-effective compared to other linear motion systems, such as ball screws or linear actuators. They provide a reliable and efficient solution for converting rotary motion into linear motion at a relatively lower cost, making them a popular choice for many applications.

- High Load Capacity: Lead screws are capable of handling significant axial loads and torque. The thread engagement between the screw and nut distributes the load over a larger surface area, allowing lead screws to support and transfer substantial loads. This makes them suitable for applications that require heavy-duty performance and load-carrying capabilities.

- Self-Locking: Lead screws have a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads helps prevent back-driving and maintains the position of the load, providing stability and safety in applications where holding the position is critical.

- Simple Design and Installation: Lead screws have a relatively simple design, consisting of a screw and a nut. This simplicity makes them easier to install and maintain compared to more complex linear motion systems. Additionally, the straightforward design allows for customization and modification to meet specific application requirements.

- Efficiency: Lead screws can achieve high mechanical efficiency in converting rotary motion to linear motion. The efficiency depends on factors such as the thread design, lubrication, and preload. With proper design and lubrication, lead screws can operate with minimal friction and energy loss, ensuring efficient power transmission.

- Versatility: Lead screws can be used in a wide range of applications across various industries. They are suitable for applications that require linear motion, precise positioning, or adjustment of components. Lead screws find applications in industries such as manufacturing, automation, robotics, aerospace, medical, and more.

These advantages make lead screws a popular choice in many applications where precise linear motion control, cost-effectiveness, high load capacity, and simplicity are essential. However, it’s important to consider specific application requirements and factors such as speed, accuracy, duty cycle, and environmental conditions when selecting the appropriate linear motion system.

<img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l1.webp" alt="China Good quality Factory Supply Single Lead Double Csk Head Screw Tornillos “><img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l2.webp" alt="China Good quality Factory Supply Single Lead Double Csk Head Screw Tornillos “>

editor by Dream 2024-10-11