Product Description

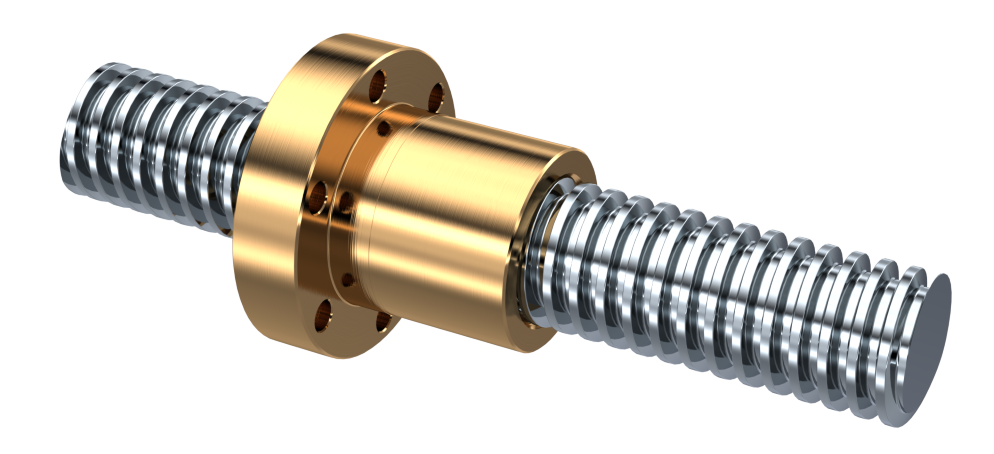

| Type: T-shaped T12 Lead screw Lead screw material:SS304 NUT material: Brass Diameter: 12mm Pitch=2mm,Lead=2mm (Nut turn a circle move 2mm) Diameter: 12mm Pitch=3mm,Lead=3mm (Nut turn a circle move 3mm) Diameter: 12mm Pitch=2mm,Lead=4mm (Nut turn a circle move 4mm) Diameter: 12mm Pitch=2mm,Lead=8mm (Nut turn a circle move 8mm) Diameter: 12mm Pitch=2mm,Lead=10mm (Nut turn a circle move 10mm) Diameter: 12mm Pitch=2mm,Lead=12mm (Nut turn a circle move 12mm) Diameter: 12mm Pitch=2mm,Lead=14mm (Nut turn a circle move 14mm) (Pitch refers to the spacing between threads.Lead refers to the rotation of the nut after a circle.) Length: 150/200/250/300/400/500/600/1000/1200mm Used for: Stepper motor driving guide rail T shape design ,make of high quality 304 stainless steel Easy to install and convenient to use |

Q.Who are we?

A.We are based in ZHangZhoug, China, start from 2015,sell to North America(30.00%),Eastern Europe(15.00%),Mid East(15.00%),Western Europe(10.00%),Southern Europe(10.00%),Southeast Asia(10.00%),South America(5.00%),Northern Europe(5.00%).

There are total about 11-50 people in our office.

Q.Can I customize the lead scew?

A.Yes, please provide your drawing, quantity and material, we can make the leas screw that you need!

Q.What’s your lead time?

A.It takes about 7-10 days for us to produce.

Q.What’s your material?

A.Material can be provided according to your requirements.

Q. How can we guarantee quality?

A.Always a pre-production sample before mass production;Always final Inspection before shipment.

Q.What can you buy from us?

A.Lead screw,Trapezoidal screw,mirror cabinet,shower cabinet.

Q. Why should you buy from us not from other suppliers?

A.specialized in producing bathroom cabinets,shower rooms and other sanitary wares. competitive price, powerful R&D ability and sincere service.

Q. What services can we provide?

A.1)Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDU,Express Delivery; Accepted Payment Currency: USD,EUR,HKD,GBP,CNY.

2)Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash;

3)Language Spoken: English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Screw Diameter: | 11-20mm |

|---|---|

| Flange: | With Flange |

| Nut Number: | Single |

| Type: | T-Shaped T12 Lead Screw |

| Lead Screw Material: | SS304 |

| Nut Material: | Brass |

| Samples: |

US$ 17.71/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that use lead screws for precise positioning?

Lead screws are widely utilized in various products and machinery that require precise positioning. Here are some examples of products and machinery that commonly use lead screws for precise positioning:

- CNC Machines: Computer numerical control (CNC) machines, including CNC mills, lathes, and routers, use lead screws to precisely position the cutting tools or workpieces. Lead screws enable accurate and repeatable movement in the linear motion systems of these machines, allowing for precise machining operations.

- 3D Printers: Lead screws are extensively used in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material, resulting in high-quality 3D prints.

- Robotics: Lead screws are integral to robotic systems that require precise positioning. They are used in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws provide accurate and controlled linear motion in robot joints, allowing for precise and coordinated movements in industrial, medical, and research robotics.

- Medical Imaging Systems: Lead screws are employed in medical imaging systems, such as computed tomography (CT) scanners and magnetic resonance imaging (MRI) machines, to precisely position the patient bed or gantry. This precise positioning is crucial for accurate imaging and diagnosis.

- Laboratory Automation Equipment: Lead screws are used in laboratory automation equipment, such as liquid handling robots and sample handling systems, for precise positioning and movement of samples, reagents, and labware. They ensure accurate and repeatable positioning required for various laboratory processes.

- Semiconductor Manufacturing Equipment: Lead screws are utilized in semiconductor manufacturing equipment, including wafer handling systems and lithography machines. They provide precise positioning and movement of wafers, masks, and other components critical for semiconductor fabrication processes.

- Camera Sliders: Lead screws are employed in camera sliders used in photography and videography applications. They enable smooth and precise linear motion of the camera along the slider, allowing for controlled tracking shots and precise camera positioning.

- Telescopes and Astronomy Equipment: Lead screws are utilized in telescopes and other astronomy equipment to precisely position optical components and achieve accurate tracking of celestial objects. They enable fine adjustments and precise pointing of telescopes for astronomical observations.

- Industrial Inspection Systems: Lead screws are used in industrial inspection systems, such as coordinate measuring machines (CMMs) and optical inspection systems, for precise movement and positioning of the inspection probes or cameras. This ensures accurate measurement and inspection of manufactured components.

These are just a few examples of the products and machinery that utilize lead screws for precise positioning. The versatility, accuracy, and reliability of lead screws make them a preferred choice in applications that require controlled linear motion and precise positioning of components.

Can you explain the impact of lead screws on the overall durability of mechanical systems?

Lead screws have a significant impact on the overall durability of mechanical systems. As essential components in many machines and mechanisms, lead screws play a crucial role in providing precise linear motion and transferring loads. Their design, quality, and maintenance directly influence the durability and reliability of the systems they are incorporated into. Here are some key factors highlighting the impact of lead screws on overall durability:

- Load-Carrying Capacity: Lead screws are responsible for transmitting axial loads between the rotating screw and the nut. The design and material selection of the lead screw determine its load-carrying capacity. Inadequate design or material choice can lead to premature wear, deformation, or failure under heavy loads, compromising the overall durability of the mechanical system.

- Backlash and Precision: Backlash refers to the play or clearance between the screw and nut in a lead screw system. Excessive backlash can result in reduced precision, inaccuracies in positioning, and decreased overall performance. Lead screws with low backlash, such as ball screws, are often preferred in applications that require high precision and repeatability. Minimizing backlash through proper design and maintenance enhances the durability and performance of the system.

- Wear and Friction: Lead screws are subject to wear and friction during operation. Continuous contact between the screw and nut can result in surface damage and increased friction, leading to accelerated wear. Adequate lubrication, regular maintenance, and proper material selection can help minimize wear and friction, extending the lifespan of the lead screw and improving the durability of the mechanical system.

- Mechanical Efficiency: The efficiency of a lead screw system influences its durability. Inefficient systems generate more heat due to friction, which can cause thermal expansion, accelerated wear, and reduced lifespan. By selecting lead screw designs with high mechanical efficiency, such as ball screws or optimized thread profiles, the overall durability of the mechanical system can be improved.

- Environmental Considerations: Lead screws operating in different environments face varying challenges that can impact their durability. Factors such as temperature extremes, exposure to moisture, chemicals, or abrasive contaminants can accelerate wear, corrosion, or degradation of the lead screw. Proper material selection, protective coatings, sealing, and regular maintenance practices can mitigate the environmental impact and enhance the overall durability of the mechanical system.

- Maintenance and Service Life: Adequate maintenance practices, including cleaning, lubrication, inspection, and adjustment, are essential for preserving the durability of lead screws and the mechanical systems they are part of. Regular maintenance helps identify and address issues early, preventing further damage and extending the service life of the system.

In conclusion, lead screws have a significant impact on the overall durability of mechanical systems. Their load-carrying capacity, precision, wear characteristics, mechanical efficiency, environmental resistance, and proper maintenance practices all contribute to the durability, reliability, and performance of the system. By considering these factors and selecting suitable lead screw designs, materials, and maintenance strategies, the overall durability of mechanical systems can be significantly improved.

Are there specific advantages to using lead screws over other linear motion systems?

Yes, there are specific advantages to using lead screws over other linear motion systems. Here are some of the advantages associated with lead screws:

- Precision and Accuracy: Lead screws offer precise and accurate linear motion control. The thread design and pitch allow for precise positioning and movement of components, making them suitable for applications that require high levels of accuracy and repeatability.

- Cost-Effectiveness: Lead screws are often more cost-effective compared to other linear motion systems, such as ball screws or linear actuators. They provide a reliable and efficient solution for converting rotary motion into linear motion at a relatively lower cost, making them a popular choice for many applications.

- High Load Capacity: Lead screws are capable of handling significant axial loads and torque. The thread engagement between the screw and nut distributes the load over a larger surface area, allowing lead screws to support and transfer substantial loads. This makes them suitable for applications that require heavy-duty performance and load-carrying capabilities.

- Self-Locking: Lead screws have a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads helps prevent back-driving and maintains the position of the load, providing stability and safety in applications where holding the position is critical.

- Simple Design and Installation: Lead screws have a relatively simple design, consisting of a screw and a nut. This simplicity makes them easier to install and maintain compared to more complex linear motion systems. Additionally, the straightforward design allows for customization and modification to meet specific application requirements.

- Efficiency: Lead screws can achieve high mechanical efficiency in converting rotary motion to linear motion. The efficiency depends on factors such as the thread design, lubrication, and preload. With proper design and lubrication, lead screws can operate with minimal friction and energy loss, ensuring efficient power transmission.

- Versatility: Lead screws can be used in a wide range of applications across various industries. They are suitable for applications that require linear motion, precise positioning, or adjustment of components. Lead screws find applications in industries such as manufacturing, automation, robotics, aerospace, medical, and more.

These advantages make lead screws a popular choice in many applications where precise linear motion control, cost-effectiveness, high load capacity, and simplicity are essential. However, it’s important to consider specific application requirements and factors such as speed, accuracy, duty cycle, and environmental conditions when selecting the appropriate linear motion system.

editor by Dream 2024-04-29