Product Description

jingbang fastener

1,customized as per the sketch

2,customized as per the 2D/3Ddrawing

3,customized as per the samples

LOW MOQ/FREE SAPMLE/FAST RESPONSE

Product Description

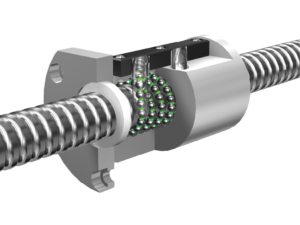

| Product Name | lead screw |

| Size | standard or non-standard according to your requirements. |

| Accept Material | AISI 303/304/316L, SUS 303/304/316, Aluminum 6061/6063/7075/2571, Brass/Bronze, Titaniumetc. |

|

Accept Finish |

Machining, Plain, Polishing, Zinc- Plated, Black Oxide, Anodizing, Passivation, Galvanized nickel alloy plated, Powder Coating, etc, as per your requirements. |

| Grade | Tempering, Hardening, Spheroidizing, Stress Relieving. 4.8,8.8,10.9,12.9etc |

| Standard | GB, DIN, ISO, ANSI/ASTM, BS, BSW, JIS, etc |

| Packing Service | We generally packing fasteners to prevent them from colliding with each other during transportation to produce scratches and surface plating, also accept customization. |

| Sample Service | Free samples will be sent to you after confirming the order, and we will charge a sample fee for some products with high value. |

Detailed Photos

Trapezoidal thread screw

We support the processing of trapezoidal screws of various diameter and can provide round flange nuts or square nuts that match them.

1.Please contact us to provide your specific requirements so that our engineers can calculate the price for you.

2. Specific operations we will try to meet customer requirements, thanks!

Packaging & Shipping

Our Advantages

1. We have Specialized QC testers to check the products quality according to customers’ needs.

2. We have IQC to check the dimensions and surface of the incoming material.

3. We have PQC to inspect full-course during the processing.

4. We have FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

FAQ

| 1, How to ensure ball lead screw every process’s quality? |

| ball lead screw Every process will be checked by our quality inspection department which insures every product’s quality. In the production of products, we will personally go to the factory to check the quality of products. |

| 2,ball lead screw delivery time? |

| For ball lead screw we have stock, within 15 days; If customized, according to your quantity, about 20-25days. |

| 3,What is your payment method? |

| Paypal, Alibaba, 30% value of T/T in advance and other 70% balance before shipping. For small order less than1000USD, would suggest you pay 100% in advance to reduce the bank charges. |

| 4, Can you provide ball lead screw sample? |

| Sure, for stocked ball lead screw, we will provide free samples and you will be charged for shipping. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C2 |

|---|---|

| Screw Diameter: | Standard or Customized |

| Flange: | Without Flange |

| Nut Number: | Single |

| Rows Number: | 1-Row |

| Nut Type: | Circulator |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What role do lead screws play in ensuring proper alignment and tightness in mechanical assemblies?

Lead screws play a crucial role in ensuring proper alignment and tightness in mechanical assemblies. They provide a reliable means of applying axial force to securely fasten components together. Here’s how lead screws contribute to alignment and tightness:

Alignment:

Lead screws aid in achieving proper alignment in mechanical assemblies through the following mechanisms:

- Linear Motion: Lead screws convert rotary motion into linear motion, allowing for controlled movement and alignment of components. By rotating the lead screw, the connected nut or threaded component moves along the screw’s axis, enabling precise positioning and alignment of the assembly.

- Thread Engagement: The mating threads of the lead screw and nut provide a positive mechanical connection. As the nut moves along the screw, the threads engage tightly, ensuring accurate alignment between the screw and the nut. This thread engagement helps maintain the desired position and alignment of components within the assembly.

- Guidance and Support: Lead screws often incorporate guidance mechanisms, such as linear bearings or sliding surfaces, to ensure smooth and accurate linear motion. These guidance systems help prevent lateral movement, minimize misalignment, and maintain the intended trajectory of the assembly, improving overall alignment.

- Positioning Accuracy: Lead screws offer precise positioning capabilities, allowing for the accurate alignment of components. The thread pitch and design, combined with the rotational input, enable controlled linear movement and positioning. This precision is critical in applications where proper alignment is essential for optimal performance and functionality.

Tightness:

Lead screws contribute to achieving tightness and secure fastening in mechanical assemblies through the following means:

- Axial Force Application: Lead screws transmit axial force to clamp or tighten components together. By rotating the lead screw, the axial force is applied through the nut or threaded component, generating a clamping action that holds the assembly tightly. This axial force helps prevent loosening, vibration, or unintended movement of the connected components.

- Self-Locking Capability: Lead screws possess a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads provides resistance to back-driving and helps maintain the tightness of the assembly. This self-locking property ensures that the assembly remains securely fastened, even in the absence of continuous power input.

- Thread Friction: The friction between the mating threads of the lead screw and nut contributes to the tightness of the assembly. When properly lubricated, the thread friction helps increase the resistance to loosening or undesired movement. By controlling the thread friction, the tightness of the assembly can be optimized to meet the specific requirements of the application.

- Preload Adjustment: Lead screws allow for preload adjustment, which is the intentional application of axial force to achieve a desired level of tightness. Preload can be applied by adjusting the initial position of the nut along the lead screw or by incorporating preload mechanisms, such as spring washers or Belleville washers. Preload optimization ensures that the assembly remains tight and secure, even under varying loads or external disturbances.

Overall, lead screws provide a reliable means of achieving proper alignment and tightness in mechanical assemblies. Their linear motion capabilities, thread engagement, guidance mechanisms, positioning accuracy, axial force application, self-locking capability, and preload adjustability all contribute to ensuring the stability, alignment, and tightness of the assembled components.

How does the choice of lead screws affect the overall performance and reliability of linear motion systems?

The choice of lead screws has a significant impact on the overall performance and reliability of linear motion systems. Different types of lead screws offer distinct characteristics and capabilities that influence factors such as accuracy, load capacity, speed, efficiency, backlash, and durability. Here are some key ways in which the choice of lead screws affects the performance and reliability of linear motion systems:

- Accuracy and Precision: The selection of an appropriate lead screw type can directly impact the accuracy and precision of linear motion systems. Lead screws with fine thread pitches or multiple starts provide higher resolution and finer positioning capabilities, resulting in improved accuracy. Choosing a lead screw with low backlash and minimal axial play helps maintain precise motion control and repeatability.

- Load Capacity: Different lead screw designs have varying load-carrying capacities. Factors such as the diameter, pitch, material, and thread type influence the ability of a lead screw to handle axial loads. Selecting a lead screw with sufficient load capacity ensures the system can handle the required loads without compromising performance or risking premature failure.

- Speed and Efficiency: Lead screw selection affects the speed and efficiency of linear motion systems. Coarser thread pitches enable faster linear speeds, making them suitable for applications that require rapid movement. However, finer thread pitches offer increased mechanical advantage and torque conversion efficiency, making them preferable for systems requiring higher force output.

- Backlash and Repeatability: Backlash, the clearance between the lead screw and nut, can impact the accuracy and repeatability of linear motion systems. The choice of lead screw influences the amount of backlash present. Lead screws with low backlash or anti-backlash mechanisms minimize positioning errors and ensure consistent repeatability, enhancing system performance and reliability.

- Lubrication and Maintenance: Different lead screw materials and designs require specific lubrication and maintenance practices to ensure optimal performance and longevity. Some lead screws may require periodic lubrication, while others may be self-lubricating or require minimal maintenance. Choosing a lead screw that aligns with the maintenance capabilities and requirements of the system simplifies upkeep and reduces the risk of premature wear or failure.

- Environmental Considerations: The choice of lead screws should also take into account the environmental conditions in which the linear motion system will operate. Factors such as temperature, humidity, exposure to contaminants, or corrosive agents can impact the performance and reliability of lead screws. Selecting lead screws with appropriate materials, surface treatments, or protective coatings ensures compatibility with the intended operating environment.

It is crucial to carefully assess the specific requirements of the linear motion system and consider factors such as load capacity, accuracy, speed, backlash, maintenance, and environmental conditions when choosing a lead screw. Consulting with manufacturers, engineers, or industry experts can provide valuable insights and guidance to select the most suitable lead screw for achieving optimal performance, reliability, and longevity in a given application.

Can you describe the various types and configurations of lead screws available in the market?

Lead screws are available in various types and configurations to suit different applications and requirements. Here’s an overview of the common types and configurations of lead screws found in the market:

- Acme Lead Screws: Acme lead screws are one of the most widely used types. They have a trapezoidal thread profile with a 29-degree thread angle. Acme screws are known for their strength, durability, and high load-carrying capacity. They offer efficient linear motion conversion and are commonly used in applications that require heavy-duty and high-load capabilities.

- Ball Screws: Ball screws are precision lead screws that incorporate ball bearings between the screw and nut. The ball bearings reduce friction, allowing for smoother and more efficient linear motion. Ball screws offer high accuracy, low backlash, and excellent repeatability. They are commonly used in applications that require high precision, such as CNC machines, robotics, and semiconductor manufacturing equipment.

- Stub Acme Screws: Stub Acme screws are similar to Acme screws but have a shallower thread depth. They offer higher efficiency and smoother operation compared to Acme screws. Stub Acme screws are commonly used in applications where space is limited or when a lighter load capacity is required.

- Buttress Screws: Buttress screws have a thread profile with one flank at a 45-degree angle and the other flank perpendicular to the screw axis. This design provides high load-carrying capacity in one direction while allowing for easy movement in the opposite direction. Buttress screws are commonly used in applications that require the transmission of heavy axial loads in a single direction, such as presses or jacks.

- Multiple-Start Screws: Multiple-start screws have two or more threads wrapped around the screw shaft. This design allows for faster linear travel per revolution compared to single-start screws. Multiple-start screws are used in applications where higher linear speeds or quick linear positioning is required.

- Thread Forms: Apart from the specific types mentioned above, lead screws can also come in different thread forms to suit specific applications. Some common thread forms include square threads, triangular threads, and rounded threads. These thread forms offer variations in load-carrying capacity, efficiency, backlash, and cost, providing options to meet specific application requirements.

- Lead Screw Configurations: Lead screws can be found in various configurations depending on the specific application. Some configurations include:

- – Standard Lead Screws: These are the most common configurations with a cylindrical shaft and threads along its length.

- – Flanged Lead Screws: These lead screws have a flange at one or both ends, providing support and alignment in certain applications.

- – Anti-Backlash Lead Screws: These lead screws incorporate mechanisms to minimize or eliminate backlash, providing more precise linear motion control.

- – Customized Lead Screws: Lead screws can be customized to meet specific application requirements, such as specific dimensions, thread pitch, end machining, or material selection.

These are some of the common types and configurations of lead screws available in the market. The selection of the appropriate lead screw type depends on factors such as load requirements, precision needs, speed, backlash tolerance, and specific application constraints.

editor by Dream 2024-04-26