Product Description

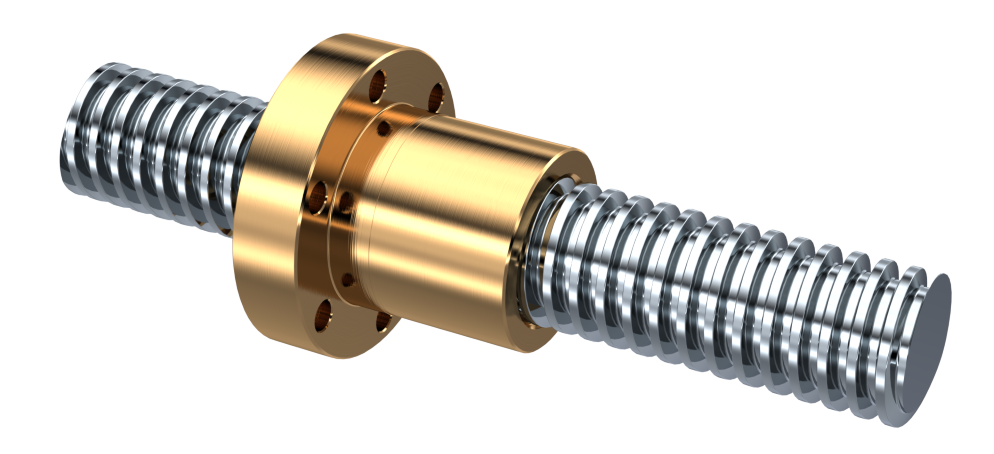

Cylinder head 10 shrinking lead screw seal

Screws are generally called wood screws; is the tip of the kind of tip, pitch larger, generally used to tighten wood parts, plastic parts. Mechanical screws, is the front of the kind of screws, the pitch is small, uniform, generally used to fasten the metal, machine parts.Our products has high quality,and long life time.Our company has passed ISO9001, ISO9001 (CQC) certification, product quality assurance.

Screw application range

1> stainless steel plate, metal plate, galvanized steel plate, engineering installation.

2> metal curtain wall metal light compartment and other indoor and outdoor installation.

3> General angle steel, channel steel, iron plate and other metal materials combined installation.

4> car trunk, container box, shipbuilding, refrigeration equipment and other assembly works.

5> automobile engine, heavy machinery, garden machinery, petrochemical.

6> aerospace, energy, machinery, chemical, military, metallurgy, mold, hydraulic.

7> motorcycles, sports equipment, cars and many other industries.

8> electronics, electrical appliances, motors, lighting, communications, home appliances, furniture.

| Brand name | HangZhou | Model | CC-153 | Type | Machine Screw |

| Head Type | Cylindrical head | Groove type | Phillips slot | Screw diameter | 8mm |

| Screw Length | 105mm | Application | Hand twist | Screw size | M6 |

| Thread tolerance | 6G | Nominal length | 110mm | Surface | Chrome |

| Material grade | Carbon steel 45H | Product grade | A | Standard type | National |

| Standard number | GB-CC-153 | Customized | yes | Specification | CC-153 |

| Material | Heat treatment |

Shipping and packaging

Via CHINAMFG shipping

North America, South America about 40 working days

Eastern Europe about 30-40 working days

Southeast Asia about 20-30 working days

Africa about 35-45 working days

India, Pakistan about 40 working days

Korea, Japan about 40 working days

Air transport

Other places around 1-3 business days

Packaging: boxes, cartons or plastic bags, or according to customer needs.

Sample service

If you need sample,you need pay the freight.

Customer Service

· 1. No question refund within 3 days.

· 2. Well trained and experienced staffs at your service.

· 3. Short lead time.

· 4. International standard matched

· 5. Non-standard / standard / OEM / ODM / customized service provided.

· 6. Small Quantity available.

· 7. Designed in accordance with customers’ request.

· 8. Packed and delivered by customers’ requirement.

Any more questions or demands, please feel free to contact us!

Our factory

GB/T 65-2000

GB/T 67-2000

GB/T 68-2000

GB/T 69-2000

GB/T 70.1-200

GB/T 70.2-2000

GB/T 70.3-2000

GB 71-85

GB-72-88

GB-73-85

GB-74-85

GB-75-85

GB/T 77-2000

GB/T 78-2000

GB/T 79-2000

GB/T 80-2000

GB 83-88

GB 84-88

GB 85-88

GB 86-88

GB/T 818-2000

GB 838-88

GB 839-88

GB 840-88

GB 946-88

GB 947-88

GB 948-88

GB 949-88

GB 2672-86

GB 2673-86

GB 2674-86

GB 5281-86

GB/T 820-2000

GB/T 821-88

GB/T 822-2000

GB 823-88

GB 825-88

GB 828-88

GB 829-88

GB 830-88

GB 831-88

GB 832-88

GB 833-88

GB 834-88

GB 835-88

GB 836-88

GB 13-88

GB 14-1998

GB 15-88

GB 29.2-88

GB 35-88

GB 37-88

GB /T794-93

GB 798-88

GB 799-88

GB 800-88

DIN 125-A GB 971-85

DIN 125-B GB97.2-85

DIN127-A GB7244

DIN 127-B GB93-87

DIN 912 GB70-85

DIN933 GB-5783-86

DIN931 GB5782-86

DIN934 GB6170-86

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Stainless Steel |

|---|---|

| Type: | Fillister |

| Groove: | Hexagon |

| Connection: | Hinged Bolts |

| Head Style: | Fillister |

| Standard: | DIN, GB, ANSI, JIS |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the design of lead screws impact their performance in different environments?

The design of lead screws plays a crucial role in determining their performance in different environments. Lead screws are mechanical devices used to convert rotational motion into linear motion. They consist of a screw (also known as the lead screw or power screw) and a nut that engages with the screw’s threads. The performance of lead screws can be influenced by various design factors, including the thread profile, lead angle, material selection, and lubrication.

Thread Profile: The thread profile of a lead screw refers to the shape of the threads on the screw and nut. Common thread profiles include square, Acme, and ball screw. The choice of thread profile affects the efficiency, backlash, and load-carrying capacity of the lead screw. For example, ball screws generally offer higher efficiency and lower backlash compared to square or Acme threads, making them suitable for applications requiring high precision and efficiency.

Lead Angle: The lead angle of a lead screw is the angle between the helix and the axis of the screw. It determines the linear distance traveled by the nut for each revolution of the screw. Lead angle influences the mechanical advantage, speed, and load-carrying capacity of the lead screw. Steeper lead angles provide higher mechanical advantage but may reduce the speed and load capacity. Shallower lead angles, on the other hand, offer higher speed but lower mechanical advantage.

Material Selection: The choice of materials for lead screws depends on the specific environmental conditions and application requirements. Factors such as mechanical strength, wear resistance, corrosion resistance, and temperature resistance need to be considered. Common materials for lead screws include stainless steel, carbon steel, and bronze. Stainless steel is often preferred for its corrosion resistance, while bronze may be chosen for its self-lubricating properties.

Lubrication: Proper lubrication is essential for the smooth operation and longevity of lead screws. Lubricants reduce friction and wear between the screw and nut, improving efficiency and reducing the chances of seizing or galling. The selection of lubricants depends on the operating conditions, such as temperature, speed, and load. For high-temperature environments, specialized high-temperature lubricants may be required.

In different environments, the design considerations for lead screws may vary. For example:

- In high-temperature environments, the selection of materials with high-temperature resistance becomes critical to prevent premature failure or deformation of the lead screw.

- In corrosive environments, materials with good corrosion resistance, such as stainless steel or specialized coatings, should be chosen to protect the lead screw from chemical degradation.

- In applications where precision is crucial, such as CNC machines or robotics, lead screws with low backlash and high efficiency, such as ball screws, are often preferred.

In summary, the design of lead screws, including thread profile, lead angle, material selection, and lubrication, significantly impacts their performance in different environments. It is important to consider the specific requirements of the application and environmental conditions to choose the most suitable lead screw design for optimal performance and longevity.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

How does a lead screw differ from other types of screws in terms of design and functionality?

A lead screw differs from other types of screws in terms of its design and functionality. Here’s a detailed explanation of the distinctions between lead screws and other screw types:

- Thread Design: Lead screws have a helical thread design, meaning the threads wrap around the screw’s cylindrical shaft in a continuous spiral. This helical thread allows for the conversion of rotary motion into linear motion. In contrast, other types of screws, such as machine screws or wood screws, typically have a straight or tapered thread design suited for fastening or joining applications.

- Linear Motion Conversion: The primary function of a lead screw is to convert rotary motion into linear motion or vice versa. It achieves this by utilizing the engagement between the helical threads on the screw and the matching threads on the nut. This capability makes lead screws suitable for applications requiring precise positioning, actuation, or adjustment of components along a linear path. In contrast, other screws are primarily used for fastening, joining, or securing objects together.

- Precision and Control: Lead screws offer precise control over linear movement due to their thread pitch and the ability to rotate the screw with precision. The pitch determines the linear distance the nut will travel for each revolution of the screw. This feature makes lead screws well-suited for applications that demand accurate positioning or adjustment. In contrast, other screws are not designed with the same level of precision or control over linear motion.

- Load Handling: Lead screws are designed to handle both axial loads (tension or compression forces) and torque. The helical threads and the engagement between the screw and nut distribute the load over a larger surface area, allowing lead screws to support and transfer significant loads. Other screw types, such as machine screws or wood screws, are primarily used for fastening and may not have the same load-bearing capabilities as lead screws.

- Applications: Lead screws find applications in various mechanical systems that require precise linear motion, such as CNC machines, 3D printers, robotic systems, and adjustable mechanisms. They are commonly used for positioning, actuation, or adjustment purposes. Conversely, other types of screws serve different purposes, such as machine screws used for fastening components together, wood screws for joining wooden materials, or self-tapping screws for creating threads in materials like metal or plastic.

Overall, the key differences between lead screws and other types of screws lie in their thread design, their ability to convert rotary motion to linear motion, the precision and control they offer, their load-handling capabilities, and the specific applications they are designed for. Understanding these distinctions is essential when selecting the appropriate screw type for a particular mechanical application.

editor by CX 2024-03-21