Product Description

Introduction

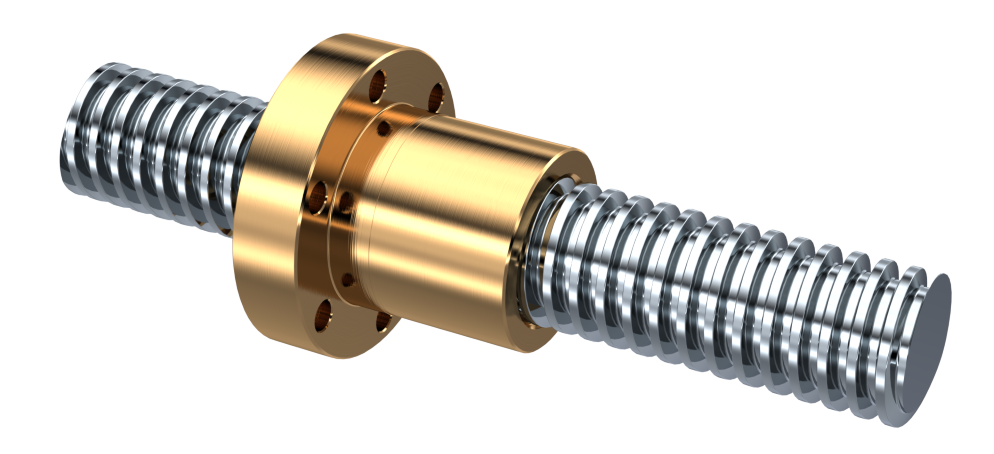

- Diameter from 4mm to 60mm for your different application, and also differenty type of nuts.

- 8mm lead screws offer an excellent way to turn rotational motion into linear motion.

-

Tr8*8-2p (4 starts),Lead Screw Diameter ∅ 8 (mm),Pitch: 2mm, Lead: 8mm

-

These Lead Screws are equipped with a large diameter that helps eliminate whipping and a high pitch which provides a quick 8mm translation for every single revolution on the screw

- The 2mm pitch offers a good trade-off between torque required to drive the screw and linear speed created. Each rotation of the lead screw will drive the mating nut precisely 8mm.

- The OD of lead-screws is just under 8mm to ensure proper fitment in an 8mm ID bearing or clamp.

-

ZS CHINAMFG screw systems feature centralizing thread forms for smooth, no-wedging performance.

-

ZS offers the largest selection of rolled CHINAMFG screw sizes in the industry. Rolled thread screws are cost effective and are stocked for quick delivery.

-

Serving a variety of functions, including fine positioning, focus adjustment, and part transport, lead screws are found in a broad spectrum of products and industries.

-

From the medical and research industries to manufacturing and packaging, lead screws are found in many applications. In addition to our basic lead screws, our design features value-added services to suit customer requirements.

-

Materials Available:Stainless Steel;Aluminum, Steel;Brass:;Bronze; Plastic;etc/as per you required

-

Processing:CNC Machining, CNC milling and turning,, grinding, bending, sheet metal fabrication,etc.

-

Surface Treatment:sand blasting, anodizing, painting,tumbling,grinding and assembling,Zinc-plated, nicke plated, chrome-plated, silver-plated, gold-plated,Passivation etc.

-

Equipments:3/4/5-axis CNC milling, CNC turning, milling machines,Grinding Machines,wire cut Machines etc;

-

Capacity:20,000 pieces per month

-

Measuring equipment:Three coordinates measuring instrument,micrometer,height gauge,hardness tester,roughness measuring instrument,caliper and various PIN gauge.

Application

- Microscopes

- Electronic Instrumentation

- Visual Inspection Equipment

- Printing, Folding, and Cutting Machines

- Blood Analyzers and ScHangZhou Machines

- 3D printers, CNC routers, lift mechanisms and automation projects.

- Precise medical devices,Industry automation,mechanical manufacturing

Feature

- High efficiency of transferring

- Good price with precision quality

- Smooth movement

- High precision, duration, and reliability

- No gap and preloading

- Produced using auto turning CNC machines

- other transmission system

- Precision ball screws

- Low friction

- Durable design

- High-speed operation* Dimension of Linear guideway

1. We have first-class testing equipment to detect linear guide various data parameters and control the quality of the linear guide.Whenever linear guides must first detected whether the quality is qualified and the unqualified linear guide will be eliminated directly.So we can get the trust of a large customer, and supply them for several years.

2. We have our own R & D capabilities, to help customers solve the problem of non-standard linear guides.We can also according to customer requirements change their own mark.

3. Price, our manufacture ensure that our prices across China are quite competitive.It is better for you to compare prices and quality among suppliers.But everyone knows you can not buy the highest quality products with the lowest price,but our product is the best quailty if you use equal price.

FAQ:

1. When can I get the quotation ?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

2. How can I get a sample to check your quality ?

After price confirmed,sample order is available to check our quality.

3. What is your main products ?

Linear motion systems,like lead screws, flexible coupling,Miniature linear guide rails,ball screws,linear rod shaft,ceramic bearings …etc. But also CNC machining centers and CNC machinable tooling boards.

4. Could you get a better price on your products ?

Yes,you can.We will give the best price on all of the products you need,which can help you to compete other companies in your markets.

5. What is the strength of your company ?

We have a engineer team,who have well experienced on product’s and machine designs.We can help you to solve the problems you meet.

Welcome to inquiry US!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Flange: | with Flange,Without Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Type: | Linear Guide Trh, Thv, Micro Type |

| Material: | Linear Guide Hgw |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended for lead screws to ensure optimal functionality?

Maintaining lead screws is crucial for ensuring their optimal functionality and longevity. Regular maintenance practices can help prevent issues such as wear, backlash, and premature failure. Here are some recommended maintenance practices for lead screws:

- Cleaning: Regularly clean the lead screw and nut to remove dirt, debris, and contaminants that can cause friction and wear. Use a soft brush or cloth to gently wipe away any buildup. Avoid using abrasive materials or harsh chemicals that can damage the surfaces.

- Lubrication: Proper lubrication is essential for reducing friction and ensuring smooth operation of the lead screw. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant for the specific application. Apply the lubricant evenly along the entire length of the screw, ensuring that it reaches the threads and engages with the nut. Be careful not to over-lubricate, as excess lubricant can attract more dirt and debris.

- Inspection: Regularly inspect the lead screw for any signs of wear, damage, or misalignment. Look for excessive backlash, unusual noise during operation, or visible signs of wear on the threads. Check the nut for any signs of wear, such as uneven or flattened threads. If any issues are detected, take appropriate measures to address them, such as replacing worn components or realigning the system.

- Tension Adjustment: If the lead screw system utilizes tensioning mechanisms, such as adjustable tension nuts or spring-loaded devices, periodically check and adjust the tension as needed. Proper tension ensures proper engagement between the screw and nut, minimizing backlash and maintaining accurate positioning.

- Protection: Protect the lead screw from environmental factors that can contribute to corrosion or damage. If the lead screw is exposed to moisture, chemicals, or extreme temperatures, consider implementing protective measures such as using covers, seals, or coatings to shield the screw and nut. This is particularly important for lead screws operating in outdoor or harsh industrial environments.

- Training and Operator Practices: Provide proper training to operators who work with lead screw systems. Ensure they understand the correct operating procedures, including any specific maintenance requirements. Encourage operators to report any abnormalities or issues promptly to prevent further damage or downtime.

By following these maintenance practices, lead screw systems can operate optimally and have a longer service life. Regular cleaning, appropriate lubrication, thorough inspection, tension adjustment, protection from external factors, and proper operator practices are all essential for ensuring the optimal functionality and reliability of lead screws.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

How does a lead screw differ from other types of screws in terms of design and functionality?

A lead screw differs from other types of screws in terms of its design and functionality. Here’s a detailed explanation of the distinctions between lead screws and other screw types:

- Thread Design: Lead screws have a helical thread design, meaning the threads wrap around the screw’s cylindrical shaft in a continuous spiral. This helical thread allows for the conversion of rotary motion into linear motion. In contrast, other types of screws, such as machine screws or wood screws, typically have a straight or tapered thread design suited for fastening or joining applications.

- Linear Motion Conversion: The primary function of a lead screw is to convert rotary motion into linear motion or vice versa. It achieves this by utilizing the engagement between the helical threads on the screw and the matching threads on the nut. This capability makes lead screws suitable for applications requiring precise positioning, actuation, or adjustment of components along a linear path. In contrast, other screws are primarily used for fastening, joining, or securing objects together.

- Precision and Control: Lead screws offer precise control over linear movement due to their thread pitch and the ability to rotate the screw with precision. The pitch determines the linear distance the nut will travel for each revolution of the screw. This feature makes lead screws well-suited for applications that demand accurate positioning or adjustment. In contrast, other screws are not designed with the same level of precision or control over linear motion.

- Load Handling: Lead screws are designed to handle both axial loads (tension or compression forces) and torque. The helical threads and the engagement between the screw and nut distribute the load over a larger surface area, allowing lead screws to support and transfer significant loads. Other screw types, such as machine screws or wood screws, are primarily used for fastening and may not have the same load-bearing capabilities as lead screws.

- Applications: Lead screws find applications in various mechanical systems that require precise linear motion, such as CNC machines, 3D printers, robotic systems, and adjustable mechanisms. They are commonly used for positioning, actuation, or adjustment purposes. Conversely, other types of screws serve different purposes, such as machine screws used for fastening components together, wood screws for joining wooden materials, or self-tapping screws for creating threads in materials like metal or plastic.

Overall, the key differences between lead screws and other types of screws lie in their thread design, their ability to convert rotary motion to linear motion, the precision and control they offer, their load-handling capabilities, and the specific applications they are designed for. Understanding these distinctions is essential when selecting the appropriate screw type for a particular mechanical application.

editor by CX 2024-03-10