Product Description

14-10K3 15-10K3 15-16K2 15-10K315-20K2 16-16K2 20-10K4 20-5K4 20-10K3 20-20K2 20-6K5 20-8K5 25-5K4 25-10K3 25-15K5 25-20K3 25-25K2 25-6K5 25-8K5 25-10K4 25-12K4 25-16K3 25-20K3 25-8K5 28-6K5 28-8K5 28-10K5 28-16K4 32-5K4 32-5. 08K4 32-6K5 32-8K5 32-8K5 32-10K5 32-15K4 32-20K3 32-32K2 32-40K2 32-8K5 32-10K5 32-12K5 32-20K4 32-25K3 32-32K2 32-10K5 32-12K5 32-16K4 32-20K4 36-6K5 36-10K5 36-12K5 36-16K5 36-20K4 36-20K4 36-36K2 38-8K5 38-10K4 38-15K4 38-16K5 38-20K4 38-25K4 38-40K2 40-5K5 40-6K5 40-8K5 40-10K5 40-20K4 40-16K5 40-10K5 40-12K5 40-16K5 40-20K4 40-30K3 40-25K4 40-40K2 40-12K5 40-16K5 45-8K5 45-10K5 45-12K5 45-16K5 45-20K4 45-25K4 45-40K3 45-12K5 45-16K5 45-20K4 50-5K5 50-8K5 50-10K5 50-12K5 50-15K5 50-16K51 50-20K4 50-25K4 50-30K4 50-35K3 50-40K3 50-30K2 50-12K5 50-16K5 50-20K5 50-50K2 50-20K4 55-16K5 63-10K5 63-12K5 63-20K5 63-40K2 63-12K5 63-16K4 63-20K5 63-25K5 70-16K4 70-20K4 80-10K5 80-12K5 80-16K4 80-20K4 80-25K4 80-30K4

R8-3A1 R8-5B1 R10-4B1 R10-5A1 R10-4B1 R12-5B1 R12-6B1 R12-10A1 R12-10B1 R12-20A1 14-4B1 R15-5B1 5-10B1 R15-20A1 R15-30A1 R16-5B1 R16-5B2 R16-10B1 R20-4B1 R20-4B2 R20-5B1 R20-5B2 R20-40A1 R20-10B1 R25-4B2 R25-5B2 R25-10B1 R25-12A1 R25-12B1 R25-12C1 R25-25A1 R25-8B1 R25-8B2 R25-10A2 R25-10B1 R25-10B2 R25-16B1 R25-20B1 R28-5B1 R28-5B2 R28-6B1 R28-6B2 R28-8B1R28-8B2 R28-8C1 R28-8C2 R28-10B1 R28-10B2 R28-12C2R28-16B2 R32-4B2 R32-5B2 R32-6B2 R32-10B2 R32-8B2 R32-10B2 R32-12B2 R32-20B1 R32-25B1 R32-10A2 R32-10B2 R32-10C1 R32-12A2 R32-12B2 R32-12C1 R32-16B1 R32-16B2 R32-16C1 R32-20B1 R32-12B2 R32-12C1 R32-15B2 R32-16B2 R36-6B2 R36-10B2 R36-16A2 R36-16B2 R36-20B1 R40-8A2 R40-8B2 R40-8C2 R40-10B2 R40-16B2 R40-10B2 R40-10C1 R40-12B2 R40-12C2 R40-16B2 R40-20A1 R40-20A2 R40-20B1 R40-20B2 R40-20C1 R40-25A1 R40-25B1 R40-10A2 R40-10B2 R40-10C2 R40-12A2 R40-12B1 R40-12B2R40-12C1 R40-12C2 R40-16A2 R40-16B1 R40-16B2 R40-16C1 R40-20A2 R40-20B1 R40-20B2 R40-20C1 R40-25A1 R40-25B1 R45-5B2 R45-8B2 R45-10B1 R45-10B2 R45-12A2 R45-16A2R45-20B2 R45-20C1 R45-20C1 R45-12B2 R45-25A1 R45-25B1 R45-25C1 R45-12B2 R45-20B2 R45-25B1 R50-8B2 R50-8B3 R50-12B1 R50-10B2 R50-20B2 R50-25B2 R50-12B1 R50-12B2 R50-16A2 R50-16B2 R50-16C2 R50-20A2 R50-20B2 R50-20C1 R50-25B2 R50-20B2 R55-10B2 R55-20B2 R55-24A1 R55-24A2 R55-24B2 R60-24A2 R60-32C1 R63-8B2 R63-10B2 R63-10B3 R63-12B2 R63-32B1 R63-16B2 R63-20B2 R63-25B2 R63-32A2 R70-32B1 R80-16B2 R80-16B3 R80-24B2 R80-32B2

8-2.5B1 10-2.5B1 10-4B1 12-4B1 16-4B1 16-5B1 16-10B1 20-5B1 20-5B2 20-5C1 20-10B1 25-5B2 25-10B1 25-10B2 28-5B1 28-5B2 28-6A2 32-5B2 32-5C1 32-6B2 32-10B1 32-10B2 40-5B2 40-6B2 40-10B2 40-12B2 40-16A2 40-16B1 50-6B3 50-6C2 50-12B2 50-20A2 63-10B2 63-10B3 63-10C2 63-20B2 80-10B3 80-10B4 80-12B3 80-16B3 80-20B2 8-2. 5T2 10-2. 5T2 10-4T2

10-20V2 12-12S2 15-10U2 15-30S2 16-1652 16-16S2 16-16S216-32V 220-20S2 20-2052 20-40V2 25-20S2 25-25S2 25-25S2 32-32S2 32-32S2 32-64V2 38-40S2 40-40S2 50-50S2 50-50S2 10-20V4 12-12S4 15-3054 16-1654 16-1654 16-16S4 16-32V4 20-2054 20-20S4 20-40V4 25-2554 25-25S4 32-32S4 32-32S4 32-64V4 38-40S4 40-40S4 50-50S4 50-50S4

15-5K3 16-5T3 20-5K3 20-5K4 25-5K3 25-5K4 25-10K5 32-5K4 32-5K6 32-10T3 32-10T4 32-10K5 32-10K6 40-5K4 40-5K6 38-10K3 40-10T3 38-10K4 40-10T4 50-5K4 50-5K6 50-10K3 50-10K4 50-10K6 63-10K6

16-1652 20-2052 25-2552 32-3252 40-40S2

R40-10B3 R45-10B3 R45-12B3 R50-10B3 R50-12B3 R50-16B3 R55-10B3 R55-12B3 R55-16B3 R63-12B3 R63-16B3 R63-16C3 R63-20B3 R80-14B3 R80-16B3 R80-20B3 R80-20C3 R80-25B3 R100-16B3 R100-20C3 R100-25B3 R100-25C3 R120-25B3 R120-25C3

2R50-30K6 2R50-40K6 2R50-40K8 2R63-40K6 2R63-40K8 2R80-50K6 2R80-50K8

R36-10Z1 R36-12X2 R40-10Y2 R40-10Z1 R50-10X1 R50-12Z2 R50-14Y2 R50-16X3 R50-16Y2 R50-16Y3 R50-16Z1 R63-10Y2 R63-14Z2 R63-16X2 R63-16Y2 R63-16Y3 R63-16Z2 R63-16Z3 R63-20X2 R63-20Y2 R63-20Y3 R63-20Z2 R80-16Y1 R80-16Z2 R80-16Z3 R80-20Y2 R80-20Y3 R80-20Z2 R80-25Y2 R80-25Y3 R80-25Z2 R100-20Y2 R100-20Y3 R100-20Z1 R100-20Z2 R100-20Z3 R100-25X2 R100-25Y2 R100-25Y3 R100-25Z2 R120-25Y2 R120-25Y3 R125-25Y2 R125-25Z2 2R50-40X2 R63-32X1 R63-32Z1 2R63-40Y2 2R63-50Y2 2R63-40X2 2R70-40X2 2R80-50X2 2R80-50Y2 R12-5K3 2R12-10K2 R15-5K4 L15-5K4 2R15-10K3 4R15-16K3 R20-5K4 2R20-10K4 4R20-20K3 R25-55 R25-10K4 4R25-25K4 R32-5K4 R32-10K5 2R32-20K3 4R32-32K2 R38-10K4 2R38-20K3 4R38-40K2 2R12-10K3 2R15-10K3 4R15-16K3 4R15-20K2 R16-5T3 R16-10T3 R20-5K4 R20-10K3 4R20-20K2 R25-5K5 R25-10K4 4R25-25K2 R32-5K4 R32-10K4 2R32-20K3 4R32-32K2 R38-10K4 2R38-20K4 4R38-40K2 R40-5K5 R40-10T3 4R40-40K2 R48-10K6 R50-5K6 R50-10T4 R63-10T4 SFK00401 SFK00601 SFK00801 SFK00802 SFK0082.5 SFK57102 SFK57104 SFK01202 SFK01402 SFK01602 SFK57102 SFK57102

SCI01604-4 SCI01605-4 SCI57104-4 SCI57105-4 SCI57104-4 SCI57105-4 SCI57110-4 SCI03204-4 SCI03205-4 SCI03210-4 SCI04005-4 SCI5711-4 SCI 0571 1-4 SCI 0571 0-4 SCI 0571 1-4

BSHR0082.5-2.5 BSHR57102-3.5 BSHR57104-2.5 BSHR01204-3.5 BSHR01205-3.5 BSHR01404-3 BSHR01604-3 BSHR01605-3 BSHR01610-2 BSHR57105-3 BSHR57105-4 BSHR57110-4

XSVR01210B1DGC5-230-P1 XSVR01210B1DGC5-280-P1 XSVR01210B1DGC5-380-P1 XSVR01210B1DGC5-480-P1 XSVR01210B1DGC5-580-P1 XSVR57171B1DGC5-399-P1 XSVR57171B1DGC5-499-P1 XSVR57171B1DGC5-599-P1 XSVR57171B1DGC5-699-P1 XSVR57171B1DGC5-799-P1 XSVR57171B1DGC5-899-P1 XSVR57171B1DGC5-999-P1 XSVR57171B1DGC5-1099-P1

XSVR0152A1DGC5-271-P1 XSVR0152A1DGC5-321-P1 XSVR0152A1DGC5-371-P1 XSVR0152A1DGC5-421-P1 XSVR0152A1DGC5-471-P1 XSVR0152A1DGC5-521-P1 XSVR0152A1DGC5-571-P1 XSVR0152A1DGC5-621-P1 XSVR0152A1DGC5-671-P1 XSVR0152A1DGC5-721-P1 XSVR0152A1DGC5-771-P1 XSVR0152A1DGC5-871-P1 XSVR0152A1DGC5-971-P1

XSVR57120A1DGC5-399-P1 XSVR57120A1DGC5-499-P1 XSVR57120A1DGC5-599-P1 XSVR57120A1DGC5-699-P1 XSVR57120A1DGC5-799-P1 XSVR57120A1DGC5-899-P1 XSVR57120A1DGC5-999-P1 XSVR57120A1DGC5-1099-P1 XSVR57120A1DGC5-1199-P1

SCR04005 SCR5711 SCR5711 SCR04040 SCR04080 SCR05005 CHINAMFG 0571 1 CHINAMFG 0571 1 SCR05050 CHINAMFG 0571 10 CHINAMFG 0571 0 CHINAMFG 0571 0 CHINAMFG 0571 1 CHINAMFG 0571 1

SSR01210 SSR01605 SSR01610 SSR01616 SSR01620 SSR57171 SSR57110 SSR57125 SSR03210 SSR03220 SSR03232 SSR5711 SSR5711 SSR04040 SSR 0571 1 SSR 0571 1 SSR05050

RFBY01616 RFBY57120 RFBY57125 RFBY03232 RFBY04040 RFBY05050

RBBY01616 RBLY01616 RBBY57120 RBLY57120 RBBY57125 RBLY57125 RBBY03232 RBLY03232 RBBY04040 RBLY04040 RBBY05050 RBLY05050

RSSY01616 RSLY01616 RSSY57120 RSLY57120 RSSY57125 RSLY57125 RSSY03232 RSLY03232 RSSY04040 RSLY04040

RFSY01616 RFSY57120 RFSY57125 RFSY03232 RFSY04040

RFBY01616-1.8 RFBY01616-3.6 RFBY57120-1.8 RFBY57120-3.6 RFBY57125-1.8 RFBY57125-3.6 RFBY03232-1.8 RFBY04040-1.8 RFBY05050-1.8

RLBF016 RLBF571 RLBF571 RLBF032 RLBF040 RLBF050

RBBY01616-1.8 RBBY01616-3.6 RBBY57120-1.8 RBBY57120-3.6 RBBY57125-1.8 RBBY57125-3.6 RBBY03232-1.8 RBBY04040-1.8 RBBY05050-1.8

RBLY01616-1.8 RBLY01616-3.6 RBLY57120-1.8 RBLY57120-3.6 RBLY57125-1.8 RBLY57125-3.6 RBLY03232-1.8 RBLY04040-1.8 RBLY05050-1.8

RFSY01616-1.8 RFSY01616-3.6 RFSY57120-1.8 RFSY57120-3.6 RFSY57125-1.8 RFSY57125-3.6 RFSY03232-1.8 RFSY04040-1.8

RSSY01616-1.8 RSSY01616-3.6 RSSY57120-1.8 RSSY57120-3.6 RSSY57125-1.8 RSSY57125-3.6 RSSY03232-1.8 RSSY04040-1.8

RSLY01616-1.8 RSLY01616-3.6 RSLY57120-1.8 RSLY57120-3.6 RSLY57125-1.8 RSLY57125-3.6 RSLY03232-1.8 RSLY04040-1.8

SF-04 SF-06 SF-08 SF-10 SF-12 SF-16 SF-20 SF-25 SF-30 SF-32 SF-40 SF-50

SS-04 SS-06 SS-08 SS-10 SS-12 SS-16 SS-20 SS-25 SS-30 SS-40 SS-50

FK-8 FK-10 FK-12 FK-15 FK-20 FK-25 FK-30

EK-6 EK-8 EK-10 EK-12 EK-15 EK-20 EK-25

BK-10 BK-12 BK-15 BK-17 BK-20 BK-25 BK-30 BK-35 BK-40

FF-6 FF-8 FK-10 FF-12 FF-15 FF-20 FF-25 FF-30

EF-6 EF-8 EF-10 EF-12 EF-15 EF-20 EF-25

BF-10 BF-12 BF-15 BF-17 BF-20 BF-25 BF-30 BF-35 BF-40

SRJ-20C SRJ-30C SRJ-40C SRJ-55C SRJ-65C

606ZZ 608ZZ 6000ZZ 6002ZZ 6204ZZ 6205ZZ 6206ZZ

700ATYDFC8P5 7001ATYDFC8P5 7002ATYDFC8P5 7204ATYDFC8P5 7205ATYDFC8P5 7206ATYDFC8P5 708ATYDFC8P5

OUR PROMISES

Product quality standards are guaranteed. Our products have got ISO 9001 & CE international quality management system. They all produced with best advanced technology.We are proactive and we offer only products complying with top standards of quality and warranty

.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Multi-column |

| Outer Dimension: | Small (28-55mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Radial Bearing |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

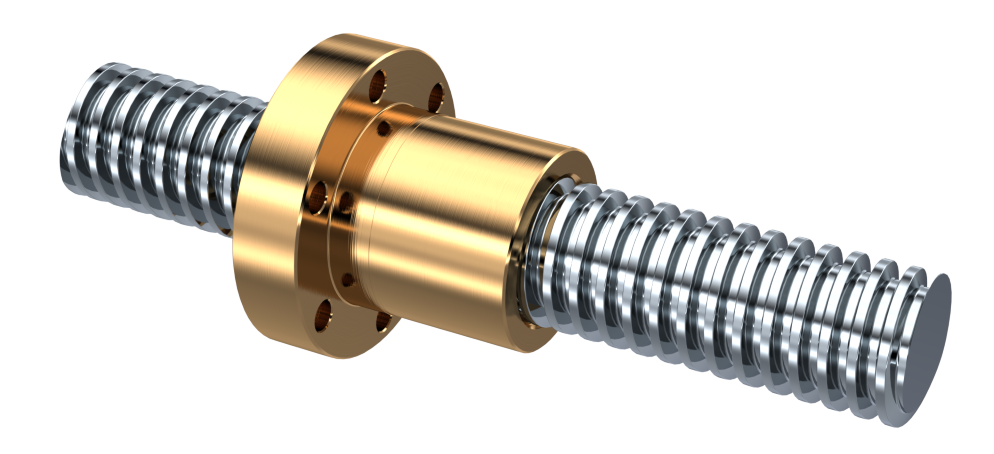

What role do lead screws play in ensuring proper alignment and tightness in mechanical assemblies?

Lead screws play a crucial role in ensuring proper alignment and tightness in mechanical assemblies. They provide a reliable means of applying axial force to securely fasten components together. Here’s how lead screws contribute to alignment and tightness:

Alignment:

Lead screws aid in achieving proper alignment in mechanical assemblies through the following mechanisms:

- Linear Motion: Lead screws convert rotary motion into linear motion, allowing for controlled movement and alignment of components. By rotating the lead screw, the connected nut or threaded component moves along the screw’s axis, enabling precise positioning and alignment of the assembly.

- Thread Engagement: The mating threads of the lead screw and nut provide a positive mechanical connection. As the nut moves along the screw, the threads engage tightly, ensuring accurate alignment between the screw and the nut. This thread engagement helps maintain the desired position and alignment of components within the assembly.

- Guidance and Support: Lead screws often incorporate guidance mechanisms, such as linear bearings or sliding surfaces, to ensure smooth and accurate linear motion. These guidance systems help prevent lateral movement, minimize misalignment, and maintain the intended trajectory of the assembly, improving overall alignment.

- Positioning Accuracy: Lead screws offer precise positioning capabilities, allowing for the accurate alignment of components. The thread pitch and design, combined with the rotational input, enable controlled linear movement and positioning. This precision is critical in applications where proper alignment is essential for optimal performance and functionality.

Tightness:

Lead screws contribute to achieving tightness and secure fastening in mechanical assemblies through the following means:

- Axial Force Application: Lead screws transmit axial force to clamp or tighten components together. By rotating the lead screw, the axial force is applied through the nut or threaded component, generating a clamping action that holds the assembly tightly. This axial force helps prevent loosening, vibration, or unintended movement of the connected components.

- Self-Locking Capability: Lead screws possess a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads provides resistance to back-driving and helps maintain the tightness of the assembly. This self-locking property ensures that the assembly remains securely fastened, even in the absence of continuous power input.

- Thread Friction: The friction between the mating threads of the lead screw and nut contributes to the tightness of the assembly. When properly lubricated, the thread friction helps increase the resistance to loosening or undesired movement. By controlling the thread friction, the tightness of the assembly can be optimized to meet the specific requirements of the application.

- Preload Adjustment: Lead screws allow for preload adjustment, which is the intentional application of axial force to achieve a desired level of tightness. Preload can be applied by adjusting the initial position of the nut along the lead screw or by incorporating preload mechanisms, such as spring washers or Belleville washers. Preload optimization ensures that the assembly remains tight and secure, even under varying loads or external disturbances.

Overall, lead screws provide a reliable means of achieving proper alignment and tightness in mechanical assemblies. Their linear motion capabilities, thread engagement, guidance mechanisms, positioning accuracy, axial force application, self-locking capability, and preload adjustability all contribute to ensuring the stability, alignment, and tightness of the assembled components.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

How does a lead screw differ from other types of screws in terms of design and functionality?

A lead screw differs from other types of screws in terms of its design and functionality. Here’s a detailed explanation of the distinctions between lead screws and other screw types:

- Thread Design: Lead screws have a helical thread design, meaning the threads wrap around the screw’s cylindrical shaft in a continuous spiral. This helical thread allows for the conversion of rotary motion into linear motion. In contrast, other types of screws, such as machine screws or wood screws, typically have a straight or tapered thread design suited for fastening or joining applications.

- Linear Motion Conversion: The primary function of a lead screw is to convert rotary motion into linear motion or vice versa. It achieves this by utilizing the engagement between the helical threads on the screw and the matching threads on the nut. This capability makes lead screws suitable for applications requiring precise positioning, actuation, or adjustment of components along a linear path. In contrast, other screws are primarily used for fastening, joining, or securing objects together.

- Precision and Control: Lead screws offer precise control over linear movement due to their thread pitch and the ability to rotate the screw with precision. The pitch determines the linear distance the nut will travel for each revolution of the screw. This feature makes lead screws well-suited for applications that demand accurate positioning or adjustment. In contrast, other screws are not designed with the same level of precision or control over linear motion.

- Load Handling: Lead screws are designed to handle both axial loads (tension or compression forces) and torque. The helical threads and the engagement between the screw and nut distribute the load over a larger surface area, allowing lead screws to support and transfer significant loads. Other screw types, such as machine screws or wood screws, are primarily used for fastening and may not have the same load-bearing capabilities as lead screws.

- Applications: Lead screws find applications in various mechanical systems that require precise linear motion, such as CNC machines, 3D printers, robotic systems, and adjustable mechanisms. They are commonly used for positioning, actuation, or adjustment purposes. Conversely, other types of screws serve different purposes, such as machine screws used for fastening components together, wood screws for joining wooden materials, or self-tapping screws for creating threads in materials like metal or plastic.

Overall, the key differences between lead screws and other types of screws lie in their thread design, their ability to convert rotary motion to linear motion, the precision and control they offer, their load-handling capabilities, and the specific applications they are designed for. Understanding these distinctions is essential when selecting the appropriate screw type for a particular mechanical application.

editor by CX 2024-01-30