Product Description

China Ball Screw Manufacturer/Factory/Supplier

Product Description

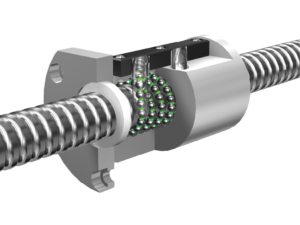

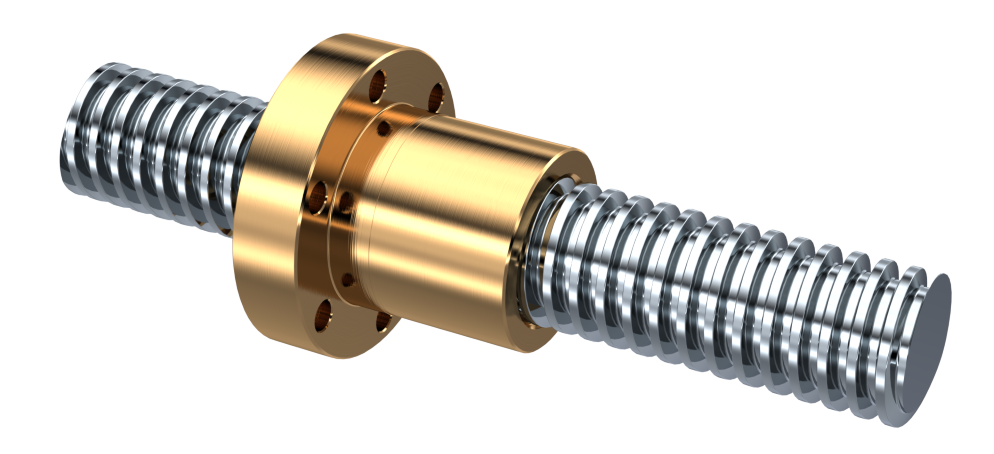

Ball Screw is made of screw and ball nut. It’s function is to turn the rotary motion into linear motion which is a future extension and development of ball screw. The significance of the development is to move into a rolling bearing from sliding action. With little frication, Ball Screw are widely used into various industrial equipment and precision instruments.

| Ball Srew Series | |

| Diameter6mm | 0601 |

| Diameter8mm | 0801 0802 |

| Diameter10mm | 1002 1004 |

| Diameter12mm | |

| Diameter16mm | |

| Diameter20mm | |

| Diameter25mm | |

| Diameter32mm | |

| Diameter40mm | |

| Diameter50mm | |

| Diameter63mm | 6310 6320 |

| Diameter80mm | 8571 |

| SFU Ball Screw Nut Model No.(plastic deflector or metal deflector ) | ||||||

| SFU1204-3;SFU1605-3;SFU1605-4; SFU1610-2; SFU2005-3;SFU2005-4;SFU2505-3; | ||||||

| SFU2505-4;SFU2510-4;SFU3205-3;SFU3205-4;SFU4005-4;SFU4571-4; SFU5571-4; | ||||||

| SFU6310-4;SFU8571-4 | ||||||

| SFK Ball Screw Model No. | ||||||

| SFK0601;SFK0801;SFK0802;SFK082.5;SFK1002;SFK1004;SFK1202;SFK1402 | ||||||

| SFS Ball Screw Model No. | ||||||

| SFS1205;SFS1210;SFS1605;SFS1610;SFS1616;SFS1620;SFS2571;SFS2510;SFS2525;SFS3210;SFS4571 | ||||||

| SFI Ball Screw Model No. | ||||||

| SFI1605;SFI1610;SFI2005;SFI2505;SFI2510;SFI3205;SFI3210;SFI4005;SFI4571 | ||||||

| SFE Ball Screw Model No. | ||||||

| SFE1616;SFE2571;SFE2525;SFE3232;SFE4040 | ||||||

| SFY Ball Screw Model No. | ||||||

| SFY1616;SFY2571;SFY2525;SFY3232;SFY4040 | ||||||

| SFA Ball Screw Model No. | ||||||

| SFA1610;SFA1620;SFA2571;SFA2510;SFA2525 | ||||||

| Ball Screw End Supports Model No. | ||||||

| BK10 BF10, BK12 BF12, BK15 BF15, BK17 BF17, BK20 BF20, BK25 BF25, | ||||||

| BK30 BF30, BK35 BF35, BK40 BF40 | ||||||

| EK06 EF06, EK08 EF08, EK10 EF10, EK12 EF12, EK15 EF15, EK20 EF20; EK25 EF25 | ||||||

| FK06 FF6, FK08 FF08,FK10 FF10, FK12 FF12, FK15 FF15, FK20 FF20, FK25 FF25, FK30 FF30 | ||||||

| Ball Screw Nut Housings Model No. (Aluminium or Iron) | ||||||

| DSG12H(1204),DSG16H(1605/1610), DSG20H(2005/2571), DSG25H(2505/2510), | ||||||

| DSG32H(3205/3210),DSG40H(4005/4571),DSG50H(5005/5571) |

Features

1.High-speed operation

2.Low friction and noise

3.High precision, duration, and reliability

4.Smooth movement

5.High efficiency of transferring

6.No gap and preloading

Applications

1.Machine tools

2.Industrial machinery

3.Printing, paper-processing, automatic machines, textiles, etc.

4.Electronic machinery

5.Robot, measuring instruments, medical equipment, X-Y table, factory automation equipment

6.Transport machinery

Product Parameters

Detailed Photos

Ball Screw Set: Ball Screw, Ball Screw Nut, Ball Screw Nut Housing,Ball Screw End Support(Fixed Side and Floated Side),Coupling; We can supply those together for you.

Ball Screw End Machining: Standard machining according to End Support Units or Customized according to drawing.

HangZhou City CHINAMFG Bearing Co., Ltd. is a professional manufacturer of linear motion products with many years’ experience. We are specialized in the producing linear shaft, linear guides, ball screws, linear bearings, linear guide blocks, ball screw end supports, linear rails, cam followers with good quality and competitive price. Our company is located in HangZhou city, ZHangZhoug province, close to HangZhou port and HangZhou city.

Our products are widely used in precise machines, fitness equipment, printing machines, packing machines, medical and food machines, textile machinery and other machines and supplementary equipment. Our products sell well in North America, West Europe, Australia, Southeast Asia, Middle East, South America and other regions.

After Sales Service

Our Quality:

Quality is the life . We use only the best quality material to ensure the standard of our product range is of the highest caliber.All products we sold out are strictly selected and tested by our QC department.

Warranty:

All products may have problem after used by a period of time. We provide 1 year warranty for all products.

Payment:

We accept payment via TT (Bank transfer), Paypal,Western Union, and Money Gram.

We accept bank transfer for large orders. For small order, you’d better pay via Paypal,Western union or Money Gram

Shipping:

We offer as many shipping options as possible, including DHL, UPS, TNT, FEDEX and EMS, Airfreight and by Sea.

FAQ

1. Are you factory or trading company?

We are professional manufacturer with most competitive price and high quality, 15 year’s experience.

2.What’s your product range?

We are specialized in producing linear shafts, linear bearings, linear guides, linear rails, ball screws,cam follower and other linear motion units.

3.Do you offer OEM&ODM services?

Yes, OEM, ODM is welcomed

4.How Can I get some samples?

We are honored to offer samples. You are requested to pay the shipping cost and some samples cost.

5.What does your factory do about quality control?

We uphold the tenet of “Quality is the future, we have passed ISO9001 certification, and we have strict procedures to control quality.

6. How can I get a quotation?

You can send quotation below or email to us. you can contact dirrectly with us through TM or WhatsApp,Skype as you like.Call any time if you are urgent.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Screw Diameter: | 11-20mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Nut Type: | Circulator |

| Customization: |

Available

|

|

|---|

What role do lead screws play in ensuring proper alignment and tightness in mechanical assemblies?

Lead screws play a crucial role in ensuring proper alignment and tightness in mechanical assemblies. They provide a reliable means of applying axial force to securely fasten components together. Here’s how lead screws contribute to alignment and tightness:

Alignment:

Lead screws aid in achieving proper alignment in mechanical assemblies through the following mechanisms:

- Linear Motion: Lead screws convert rotary motion into linear motion, allowing for controlled movement and alignment of components. By rotating the lead screw, the connected nut or threaded component moves along the screw’s axis, enabling precise positioning and alignment of the assembly.

- Thread Engagement: The mating threads of the lead screw and nut provide a positive mechanical connection. As the nut moves along the screw, the threads engage tightly, ensuring accurate alignment between the screw and the nut. This thread engagement helps maintain the desired position and alignment of components within the assembly.

- Guidance and Support: Lead screws often incorporate guidance mechanisms, such as linear bearings or sliding surfaces, to ensure smooth and accurate linear motion. These guidance systems help prevent lateral movement, minimize misalignment, and maintain the intended trajectory of the assembly, improving overall alignment.

- Positioning Accuracy: Lead screws offer precise positioning capabilities, allowing for the accurate alignment of components. The thread pitch and design, combined with the rotational input, enable controlled linear movement and positioning. This precision is critical in applications where proper alignment is essential for optimal performance and functionality.

Tightness:

Lead screws contribute to achieving tightness and secure fastening in mechanical assemblies through the following means:

- Axial Force Application: Lead screws transmit axial force to clamp or tighten components together. By rotating the lead screw, the axial force is applied through the nut or threaded component, generating a clamping action that holds the assembly tightly. This axial force helps prevent loosening, vibration, or unintended movement of the connected components.

- Self-Locking Capability: Lead screws possess a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads provides resistance to back-driving and helps maintain the tightness of the assembly. This self-locking property ensures that the assembly remains securely fastened, even in the absence of continuous power input.

- Thread Friction: The friction between the mating threads of the lead screw and nut contributes to the tightness of the assembly. When properly lubricated, the thread friction helps increase the resistance to loosening or undesired movement. By controlling the thread friction, the tightness of the assembly can be optimized to meet the specific requirements of the application.

- Preload Adjustment: Lead screws allow for preload adjustment, which is the intentional application of axial force to achieve a desired level of tightness. Preload can be applied by adjusting the initial position of the nut along the lead screw or by incorporating preload mechanisms, such as spring washers or Belleville washers. Preload optimization ensures that the assembly remains tight and secure, even under varying loads or external disturbances.

Overall, lead screws provide a reliable means of achieving proper alignment and tightness in mechanical assemblies. Their linear motion capabilities, thread engagement, guidance mechanisms, positioning accuracy, axial force application, self-locking capability, and preload adjustability all contribute to ensuring the stability, alignment, and tightness of the assembled components.

How do lead screws contribute to the adaptability and versatility of mechanical systems in different settings?

Lead screws play a significant role in enhancing the adaptability and versatility of mechanical systems across various settings. Their unique characteristics and capabilities enable precise linear motion, load handling, and control, making them valuable components in a wide range of applications. Here are some key ways in which lead screws contribute to the adaptability and versatility of mechanical systems:

- Precise Positioning: Lead screws provide accurate and repeatable linear motion, allowing for precise positioning of components or loads within a mechanical system. By converting rotational motion into linear motion, lead screws enable controlled and incremental movement, making them ideal for applications that require precise positioning, such as CNC machinery, 3D printers, or automated assembly systems.

- Variable Speed and Velocity: Lead screws offer flexibility in adjusting speed and velocity profiles within a mechanical system. By controlling the rotational speed of the screw, the linear speed and velocity can be varied as required. This adaptability is beneficial in applications that involve changing speed requirements, such as conveyor systems, material handling equipment, or packaging machinery.

- Load Handling Capability: Lead screws can handle a wide range of load capacities, making them adaptable to different mechanical system requirements. They possess high load-carrying capacities and can transmit substantial axial forces, enabling the manipulation of heavy loads. Lead screws find applications in various settings, including lifting mechanisms, industrial automation, aerospace systems, or medical equipment, where load handling is a critical factor.

- Compact Design: Lead screws offer a compact and space-efficient design, allowing for their integration into systems with limited space. Their axial configuration and threaded structure make them suitable for applications where size constraints exist. Lead screws are commonly used in compact devices and systems such as miniature robotics, precision instruments, or medical devices, where space optimization is essential.

- Cost-Effectiveness: Lead screws provide a cost-effective solution for linear motion compared to alternatives such as linear actuators or ball screws. They offer a balance between performance, precision, and cost, making them an economical choice for various applications. Lead screws are widely used in industrial machinery, automotive systems, or consumer products, where cost considerations are important.

- Easy Installation and Maintenance: Lead screws are relatively easy to install and maintain, contributing to their adaptability in different settings. They can be integrated into existing systems or retrofitted without significant modifications. Maintenance tasks such as lubrication or inspection can be performed with relative ease. This ease of installation and maintenance makes lead screws suitable for applications requiring quick deployment, frequent adjustments, or serviceability.

Overall, lead screws provide adaptability and versatility to mechanical systems by enabling precise positioning, variable speed control, efficient load handling, compact design, cost-effectiveness, and ease of installation and maintenance. Their capabilities make them widely applicable across industries and settings, offering a reliable and flexible solution for achieving linear motion requirements in diverse mechanical systems.

What is a lead screw, and how is it used in mechanical applications?

A lead screw is a type of threaded shaft used in mechanical applications to convert rotary motion into linear motion or vice versa. It consists of a screw with a helical thread and a matching nut with corresponding threads. The lead screw and nut are designed in such a way that when the screw is rotated, it moves the nut along its length, resulting in linear motion.

The primary purpose of a lead screw is to transmit motion and force between rotating and linearly translating components in a mechanical system. It offers precise control over linear movement and is commonly used in various applications, including but not limited to:

- Precision Positioning: Lead screws are widely used in applications that require precise positioning, such as CNC machines, 3D printers, and robotic systems. By coupling the lead screw to a motor or handwheel, the rotational motion can be translated into precise linear movement, allowing for accurate positioning of components or tools.

- Actuation and Adjustment: Lead screws are often utilized for actuation and adjustment mechanisms in equipment and machinery. They can be employed to raise or lower platforms, adjust the height of work surfaces, control the position of tool heads, or move components along a linear path. Lead screws provide a straightforward and reliable means of achieving controlled linear motion in these applications.

- Load Transfer: Lead screws can also serve as load-bearing elements in mechanical systems. They can transmit axial loads and handle tension or compression forces, making them suitable for applications that require smooth and controlled lifting or lowering of heavy loads. In such cases, the lead screw is often combined with thrust bearings or other supporting elements to handle the applied loads.

- Manual and Handwheel Operations: Lead screws are commonly used in manual and handwheel-operated systems. By incorporating a handle or handwheel, the user can rotate the lead screw directly, enabling manual adjustment or movement of components. This is frequently seen in applications like manual stage positioning, height adjustment mechanisms, or manual clamping systems.

- Power Transmission: In some cases, lead screws can be employed for power transmission purposes. While they are not as efficient as other transmission methods like gears or belts, lead screws can be used to transfer torque between rotating shafts and linearly translating components. This is often seen in applications where the primary focus is on converting rotational motion into linear motion rather than optimizing power transmission efficiency.

Lead screws come in various designs, including single-start and multi-start threads, different thread pitches, and varying lead screw and nut materials. The selection of a lead screw depends on the specific requirements of the application, such as load capacity, desired speed, precision, and environmental conditions. Factors like backlash, efficiency, and maintenance requirements should also be considered when choosing a lead screw for a particular mechanical application.

editor by CX 2024-01-09